Beamline phone numbers:

+44 (0) 1235 77 8617

+44 (0) 1235 77 8713

Principal Beamline Scientist:

Nick Terrill

Tel: +44 (0) 1235 778047

E-mail: [email protected]

Email: [email protected]

Tel: +44 (0)1235 56 7675

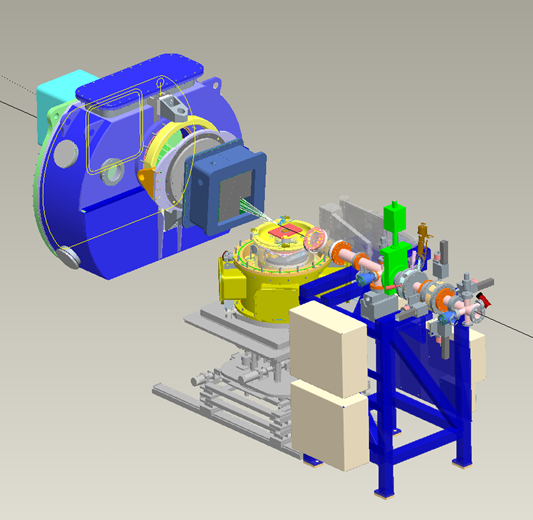

The beam conditioning section for I22, just upstream of the sample, had grown organically since first designed. The I22 BCO upgrade Project, planned to improve the performance and usability of the experimental hutch beamline components, to deliver quality, versatile beam to the sample area is now complete. The upgrade moved I22's microfocus capability from a drop-in endstation to a permanently installed solution that can be driven in and out of the beam dramatically reducing swap-over time between these two modes of operation (days to minutes) and improving data quality.

We have included a number of additional or improved components that will enhance the capability of this section of the beamline.

These include:

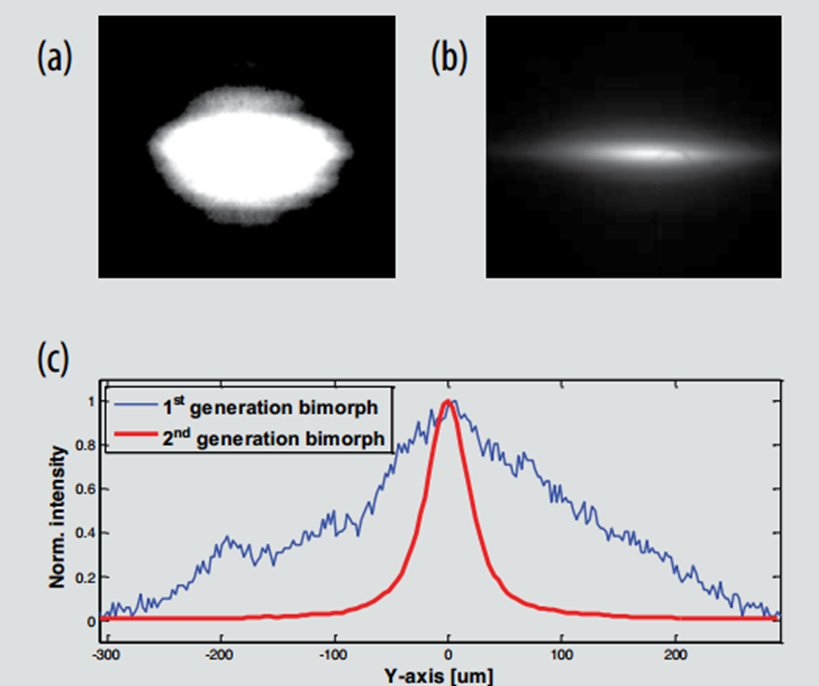

This project, to sequentially repolish the two bimorph mirrors of I22 while keeping the beamline operational with Diamond’s spare bimorph mirror, is now complete.

I22’s bimorph mirrors were in the first batch of bimorph mirrors received by Diamond. They appear to have suffered from surface damage at the piezo ceramic junctions during their early life cycle. As such it was initially impossible to fully optimise the performance of the I22 beamline to deliver the variable focus expected. It also prevented full exploitation of the Micro Focus end station on I22. Repolishing of the two I22 mirrors has seen significant improvements for I22 with this modest upgrade.

Both mirrors have now been repolished and have lead to significantly improved focusing capability. The results for the VFM are shown below

We have established a new Sample Environment Development lab in Lab 38. Supported by a Sample Environment Support Scientist the lab will be the first port of call for all users who wish to incorporate their sample environment into the data acquisition system on I22. This infrastructure capability includes a cut down mock-up of the essential beamline equipment including breadboards, motorised stages, geobricks and some of the data acquisition infrastructure as well as a dedicated, fully featured, GDA and EPICS environment.

We are finalising the infrastructure for the lab and would welcome ideas for potential consortia for collaboration on sample environment development. Please contact [email protected] or your local contact to discuss further.

This upgrade enables I22 to work in grazing incidence mode for thin film materials and includes a hexapod sample platform and environmental chamber together with a remodelled SAXS detector platform with multiple beamstops for direct, reflected and specular beams.

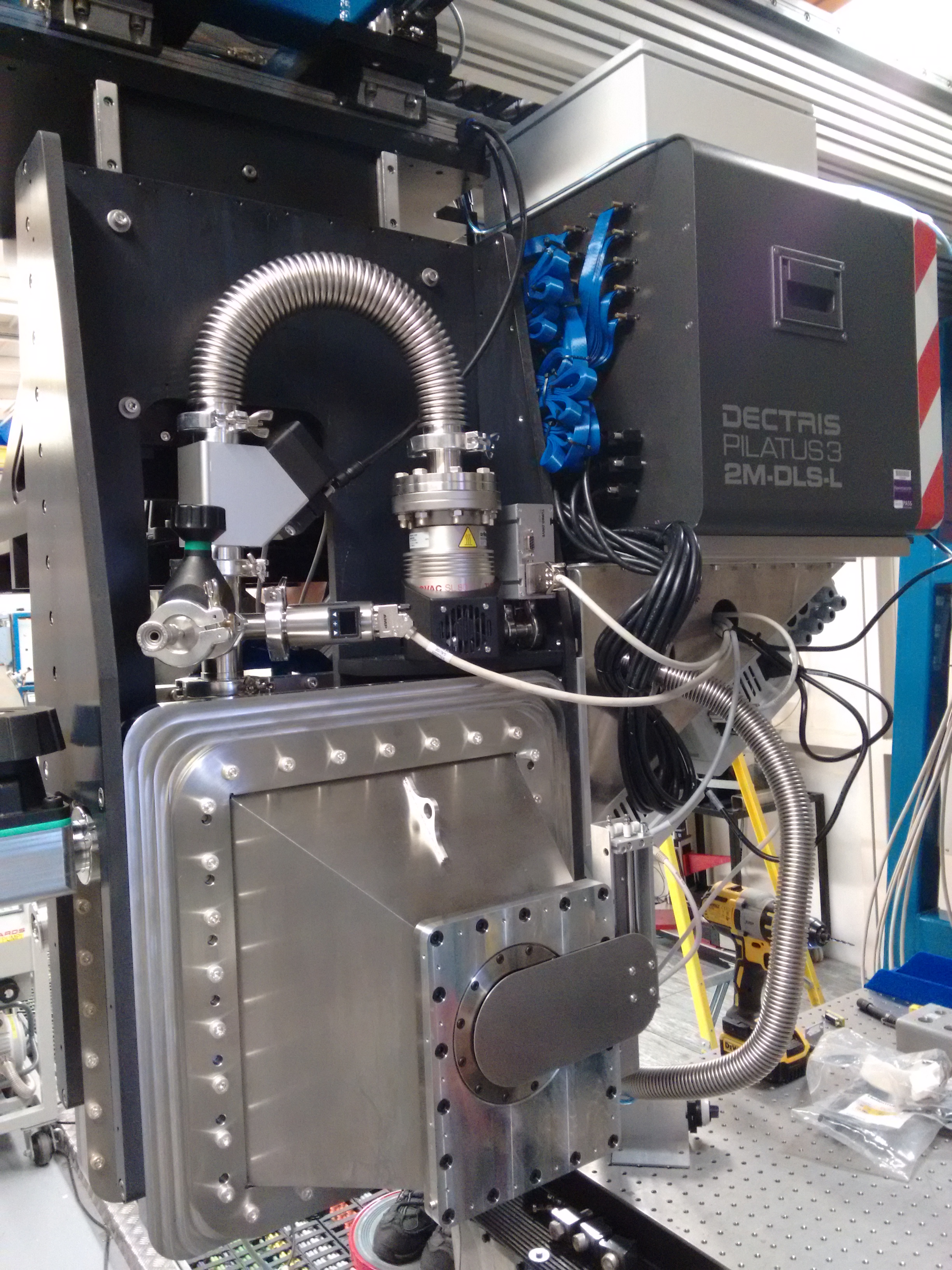

This project has now delivered a replacment Silicon pixel based system for the final gas based detector on I22, HOTWAXS. I22 has purchased a 21 module device in L shaped geometry with P3 technology from Dectris. This gives I22 some 2D capability in simultaneous 2D SAXS/WAXS measurements.

The project has included the purchase of the detector and infrastructural changes to I22 to accommodate the new in vacuum detector shape.

Diamond Light Source is the UK's national synchrotron science facility, located at the Harwell Science and Innovation Campus in Oxfordshire.

Copyright © 2022 Diamond Light Source

Diamond Light Source Ltd

Diamond House

Harwell Science & Innovation Campus

Didcot

Oxfordshire

OX11 0DE

Diamond Light Source® and the Diamond logo are registered trademarks of Diamond Light Source Ltd

Registered in England and Wales at Diamond House, Harwell Science and Innovation Campus, Didcot, Oxfordshire, OX11 0DE, United Kingdom. Company number: 4375679. VAT number: 287 461 957. Economic Operators Registration and Identification (EORI) number: GB287461957003.