Principal Beamline Scientist:

Gwyndaf Evans

Tel: +44 (0) 1235 778164

E-mail: [email protected]

Email: [email protected]

Tel: +44 (0) 1235 778926

VMXm has a sample preparation area dedicated to the testing and preparation of sample supports prior to data collection on the beamline.

The lab contains the following equipment:

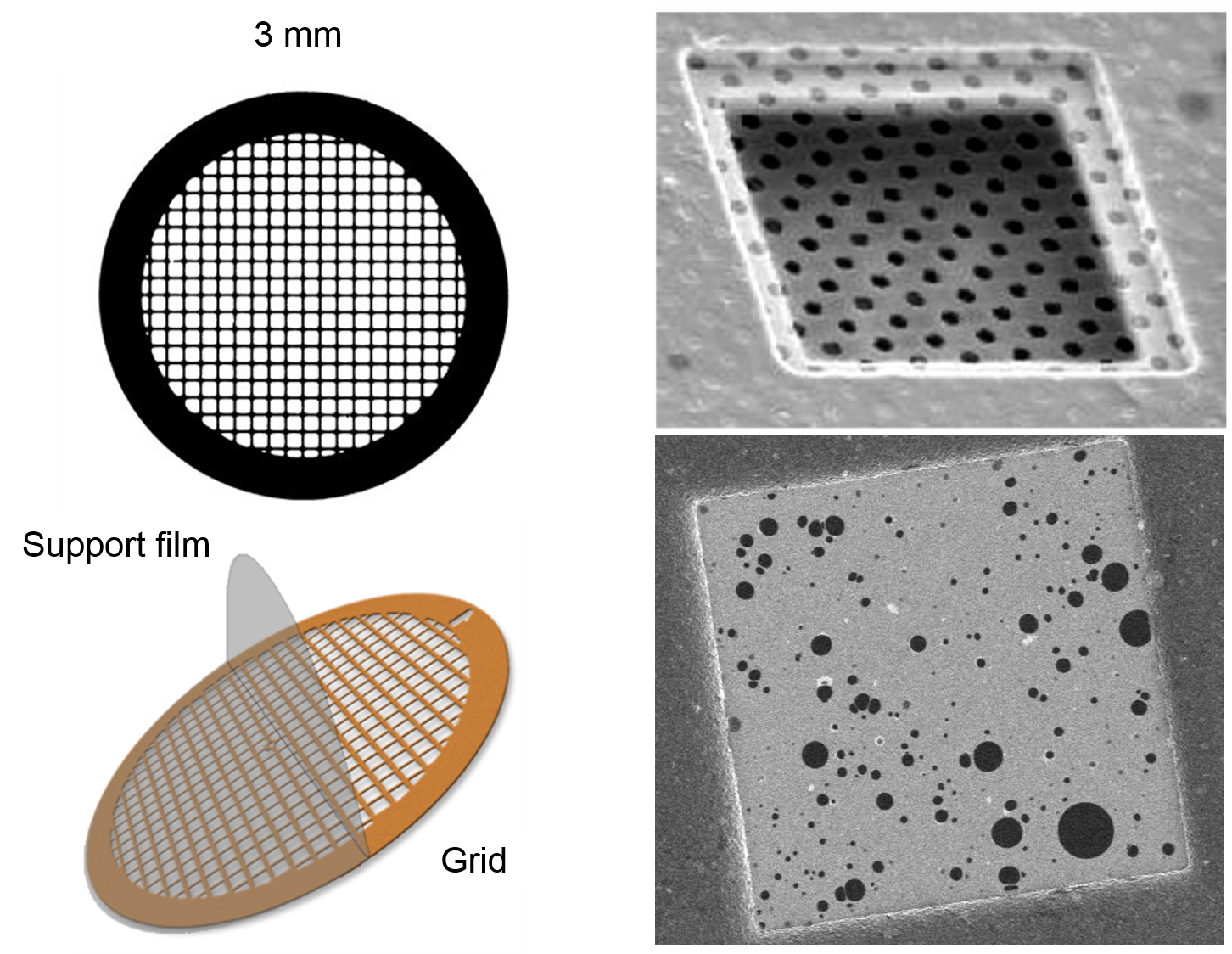

Unlike standard MX beamlines, VMXm will be using a lot of sample preparation protocols from cryo-EM. The crystals will be mounted on TEM grids. These are 3 mm diameter discs usually made from copper, gold or nickel. The grids can be purchased with varying sizes of grid spacing, and support material. Usual support materials consist of a carbon based polymer with holes that allow liquid to be wicked away.

Grids are first treated with a glow discharge treatment, creating a negatively charged surface which allows easy spreading of the crystal suspension on the grid. The VMXm sample preparation lab houses a Pelco easiGlow discharge cleaning system for this purpose.

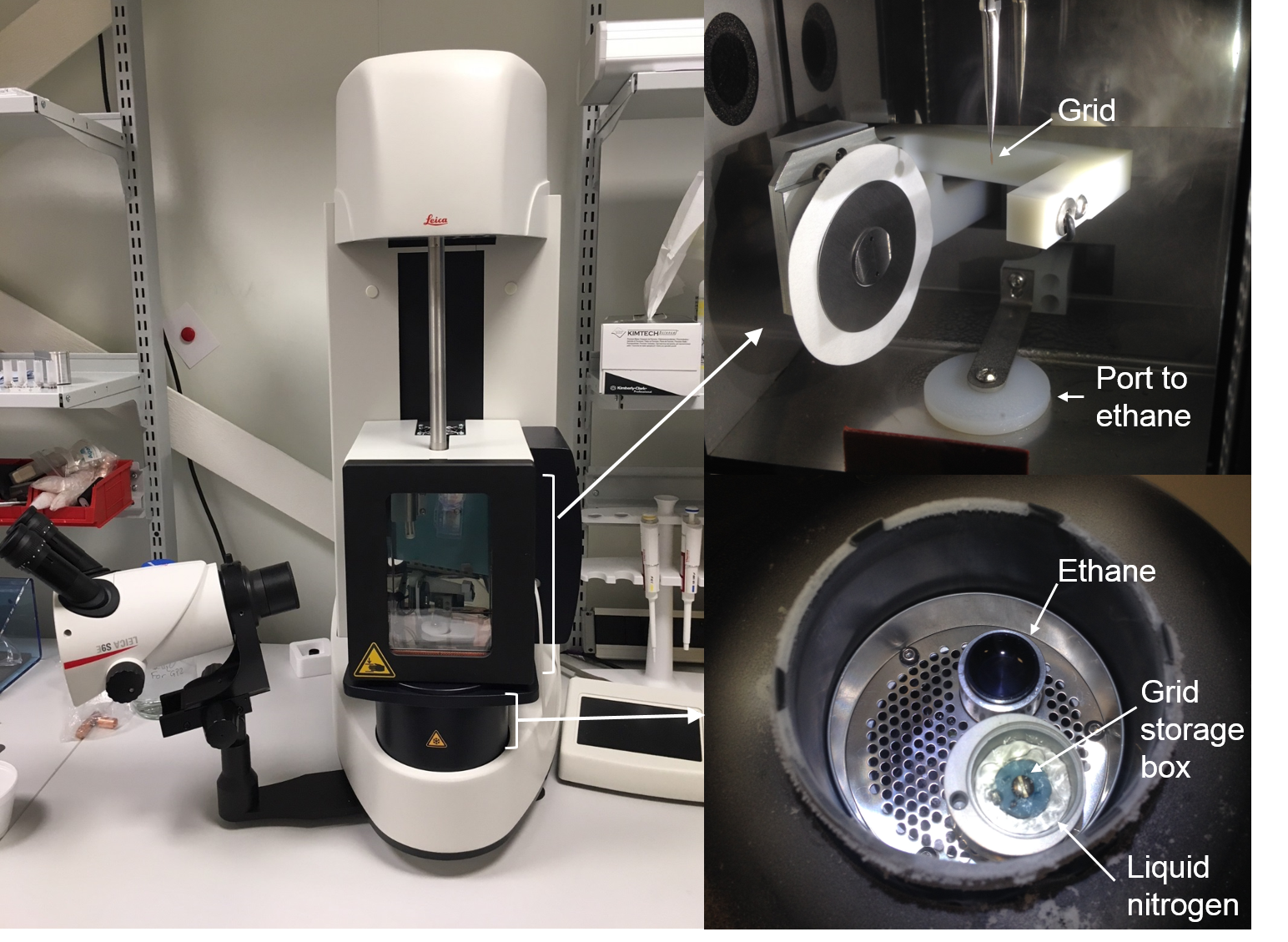

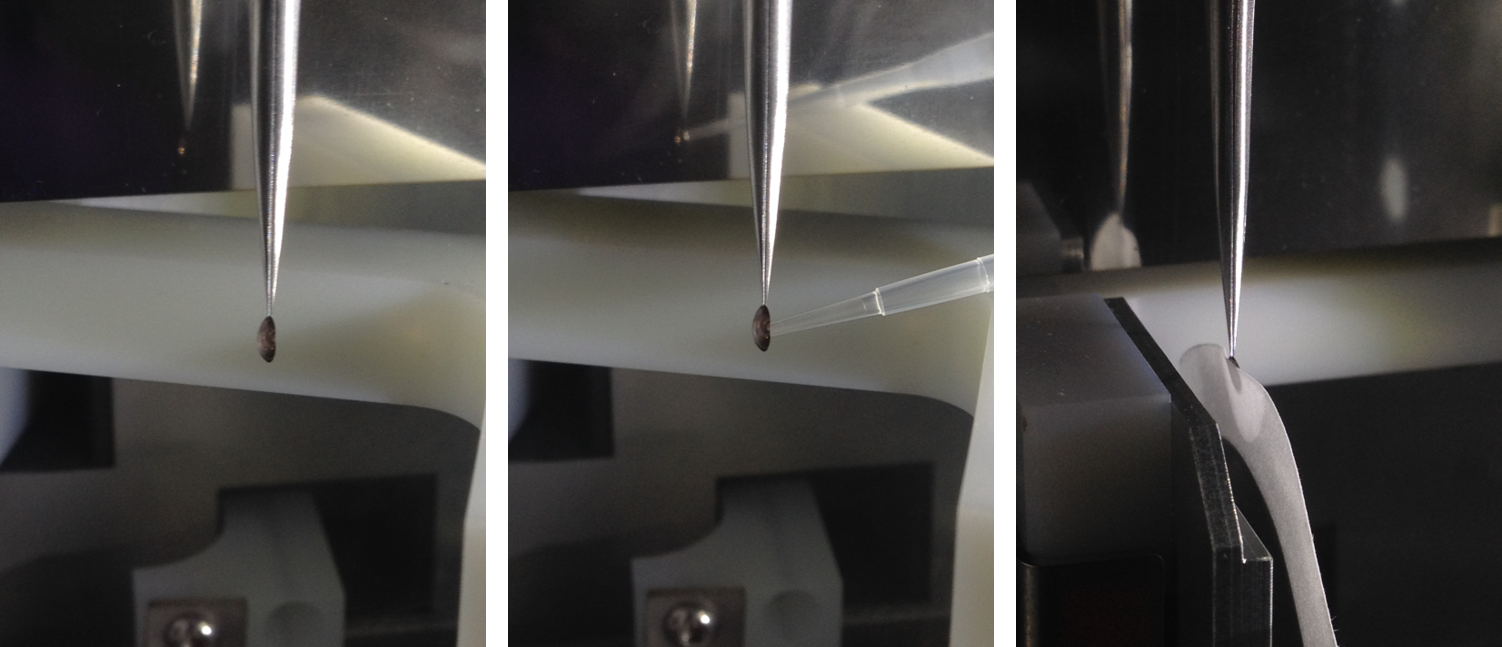

Crystal suspensions are then applied to these pre-prepared grids inside the humidity chamber of the Leica EM GP2. Samples are maintained at a high humidity to keep the crystals hydrated, while they are then blotted with filter paper to remove excess liquid. This leaves the crystals mounted nicely on the thin carbon support of the grids, with a small amount of mother liquor remaining around the crystals. The majority of the liquid is removed to improve the signal to noise when diffraction data is collected on the beamline. Once blotted the crystals are then quickly plunge cooled into a container of liquid ethane.

Leica EM GP2 housed within the VMXm sample preparation lab.

A TEM grid held with tweezers inside the Leica EM GP2 humidity chamber. A crystal suspension is pipetted onto the grid and then blotted before plunge freezing in liquid ethane. After plunge freezing the grid is transferred into the grid storage box which is surrounded in liquid nitorgen to maintain the low temperature. The grid box can hold four prepared grids.

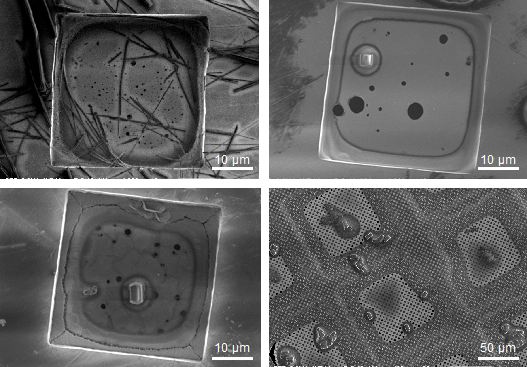

Once the grids have been prepared in the Leica EM GP2, they can be imaged within the offline SEM at cryogenic temperatures. This is a useful step to ensure samples are well prepared, and that the concentration of crystals on the grid is optimal before taking them to the beamline. This can also be a useful step to confirm whether microcrystals are present in solution. With crystals smaller than a few microns it can be hard to confirm this under a normal optical microscope.

Examples of a range of crystals prepared with the Leica EM GP2 and imaged within the SEM.

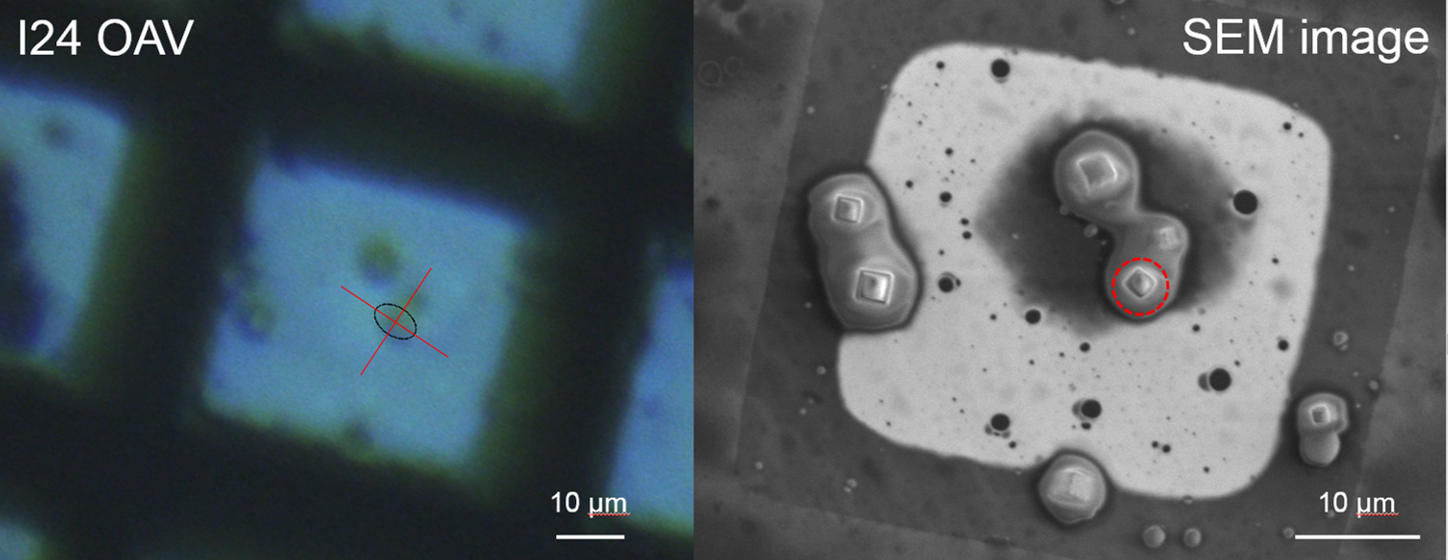

An image of crystals prepared on a TEM grid on the I24 on-axis microscope on the beamline. These are compared with the same area of the grid imaged with the SEM.

Once samples have been prepared on TEM grids and checked in the offline SEM, samples can be loaded in the custom sample holders. Grids are carefully placed in the 3mm diameter hole, where there is a small ledge to hold the grids in a place. A cicrclip is then inserted on top of the grid, compressing and holding the grid in place within the holder.

Once grids have been placed in the sample holders they are ready to be loaded into the sample cartridge for loading onto the beamline. The catridge holds 5 sample, and is loaded in a custom foam dewar designed to fit the beamline loading station.

Diamond Light Source is the UK's national synchrotron science facility, located at the Harwell Science and Innovation Campus in Oxfordshire.

Copyright © 2022 Diamond Light Source

Diamond Light Source Ltd

Diamond House

Harwell Science & Innovation Campus

Didcot

Oxfordshire

OX11 0DE

Diamond Light Source® and the Diamond logo are registered trademarks of Diamond Light Source Ltd

Registered in England and Wales at Diamond House, Harwell Science and Innovation Campus, Didcot, Oxfordshire, OX11 0DE, United Kingdom. Company number: 4375679. VAT number: 287 461 957. Economic Operators Registration and Identification (EORI) number: GB287461957003.