Beamline Phone Number:

+44 (0) 1235 778711

Principal Beamline Scientist:

Alessandro Bombardi

Tel: +44 (0) 1235 778087

E-mail: [email protected]

Email: [email protected]

Tel: +44 (0) 1235 778056

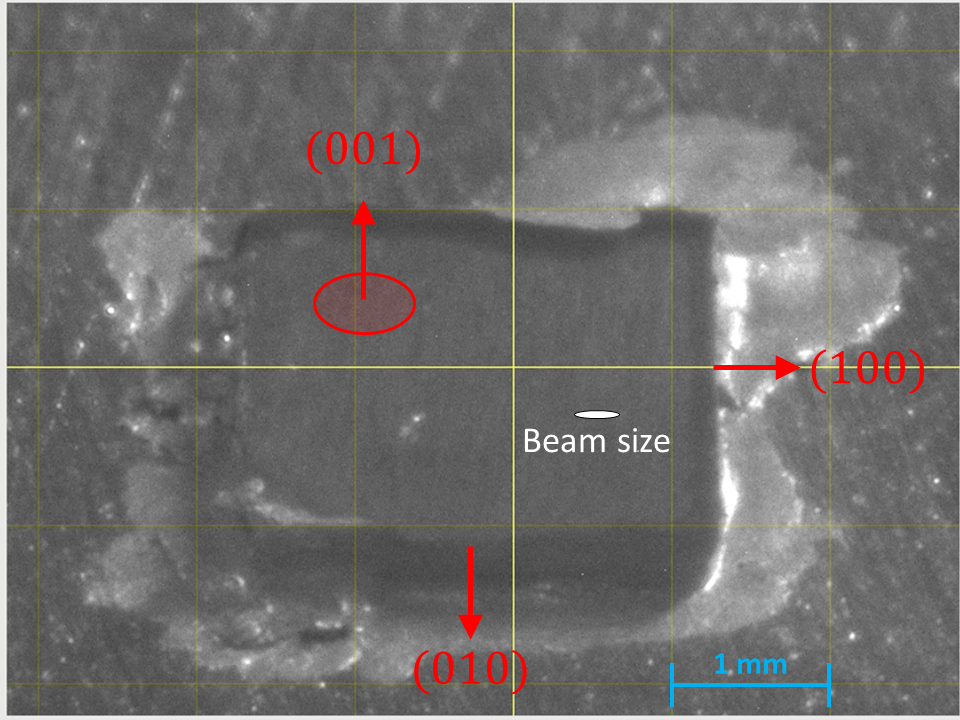

On I16, single crystal samples are typically mounted in reflection geometry, requiring an clean, flat surface to achieve maximum reflected intensity.

Typically samples are mounted in the beam position on the diffractometer. In the case where cryogenic temperatures are not required, the "wedding cake" is used that supports standard Huber goniometric heads. If low temperatures are required, the ARS cryocooler is used and this takes specific copper mounts.

The diffractometer has an x/y/z stage with motion range:

|

Sample axis |

Motion range |

|---|---|

| x | ~4.5 mm |

| y | ~4.5 mm |

| z | ~20 mm |

To get the best diffracted intensity from the sample, it is important to have a smooth, flat surface with a well known orientation. Ideally this surface should be close to the direction along which you want to measure - for example, if you want to look at a magnetic moment directed along the c* axis, the strongest magnetic reflections are typically along at high (00L) reflections with θ close to 90 degrees, so a sample should be prepared with a shiny / polished {001} surface oriented normal to the mounting plate.

|

|

|

Samples are typically adhered directly to the sample mount. Silver paint or silver epoxy is a common choice due to the ease of use and the thermally conductive properties. GE Varnish, carbon tape and stycast can also be used an all have advantages and disadvantages.

Below is a list of common methods used to adhere samples. Methods routinely available in the beamline lab are starred (*).

|

Glue |

Advantages |

Disadvantages |

|---|---|---|

| Silver paint* |

|

|

| Sliver Epoxy |

|

|

| GE Varnish* |

|

|

| Thermoplastic wax |

|

|

| Carbon tape* |

|

|

| Double sided-tape* |

|

|

|

Silicon grease Silicone Oil Vacuum grease* |

|

|

| Superglue* |

|

|

| Stycast |

|

|

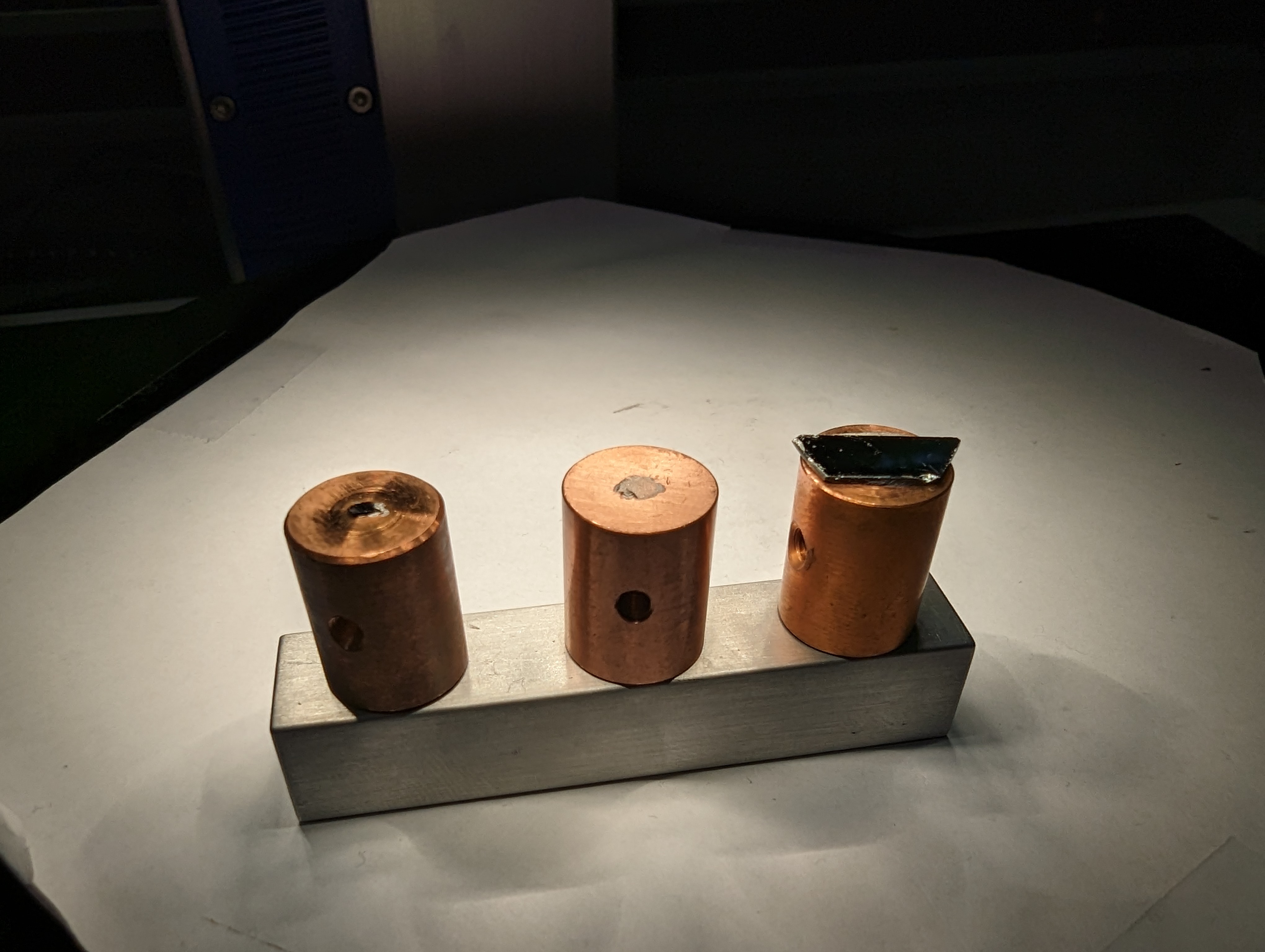

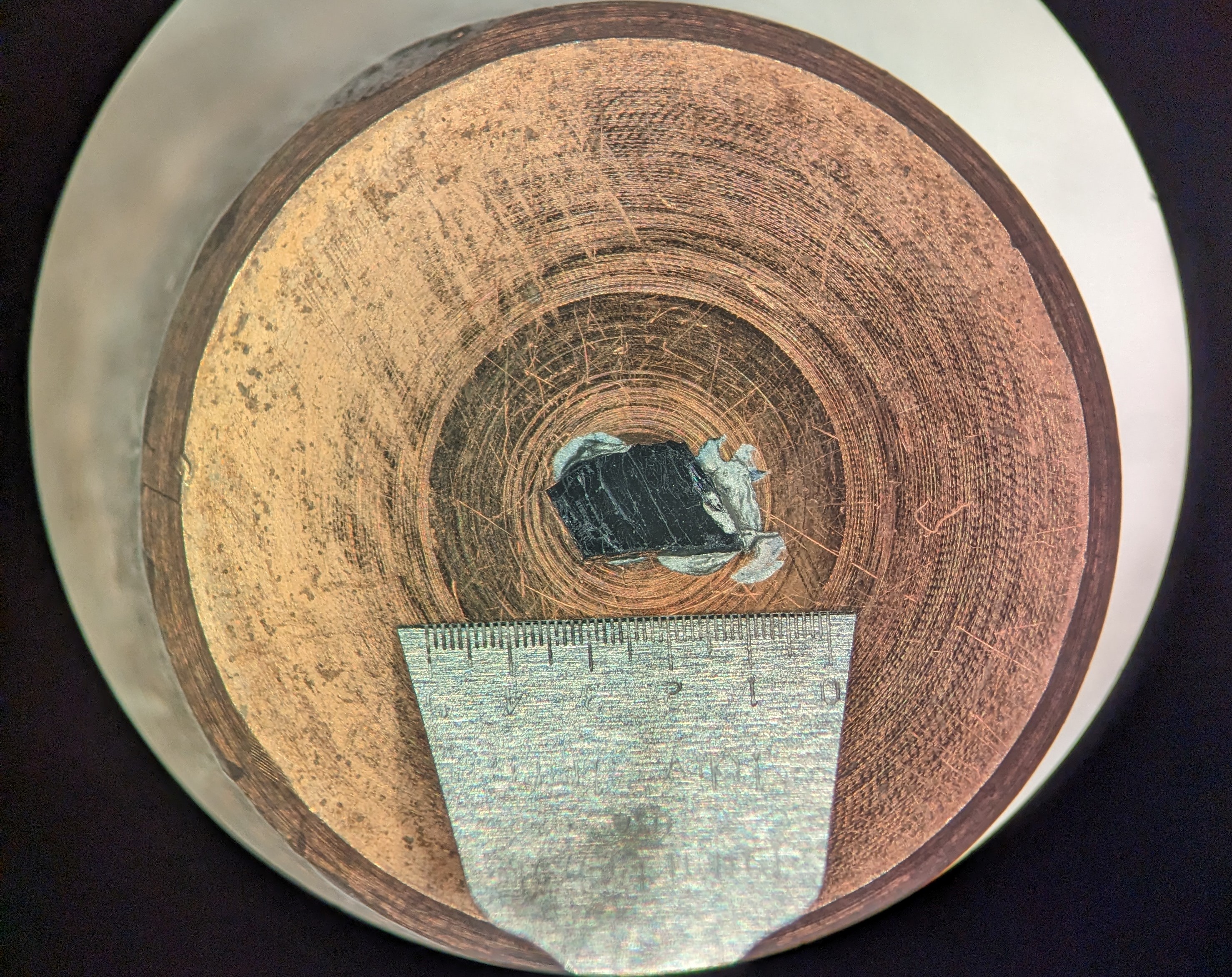

For the ARS cryostats, samples are mounted onto a copper mount as shown below.

Samples are adhered to the mount typically using silver paint, or another thermally conductive epoxy.

| 12 mm | 2 mm | 20 mm |

|---|---|---|

|

|

|

|

|

|

| Diameter | Photo | Notes |

|---|---|---|

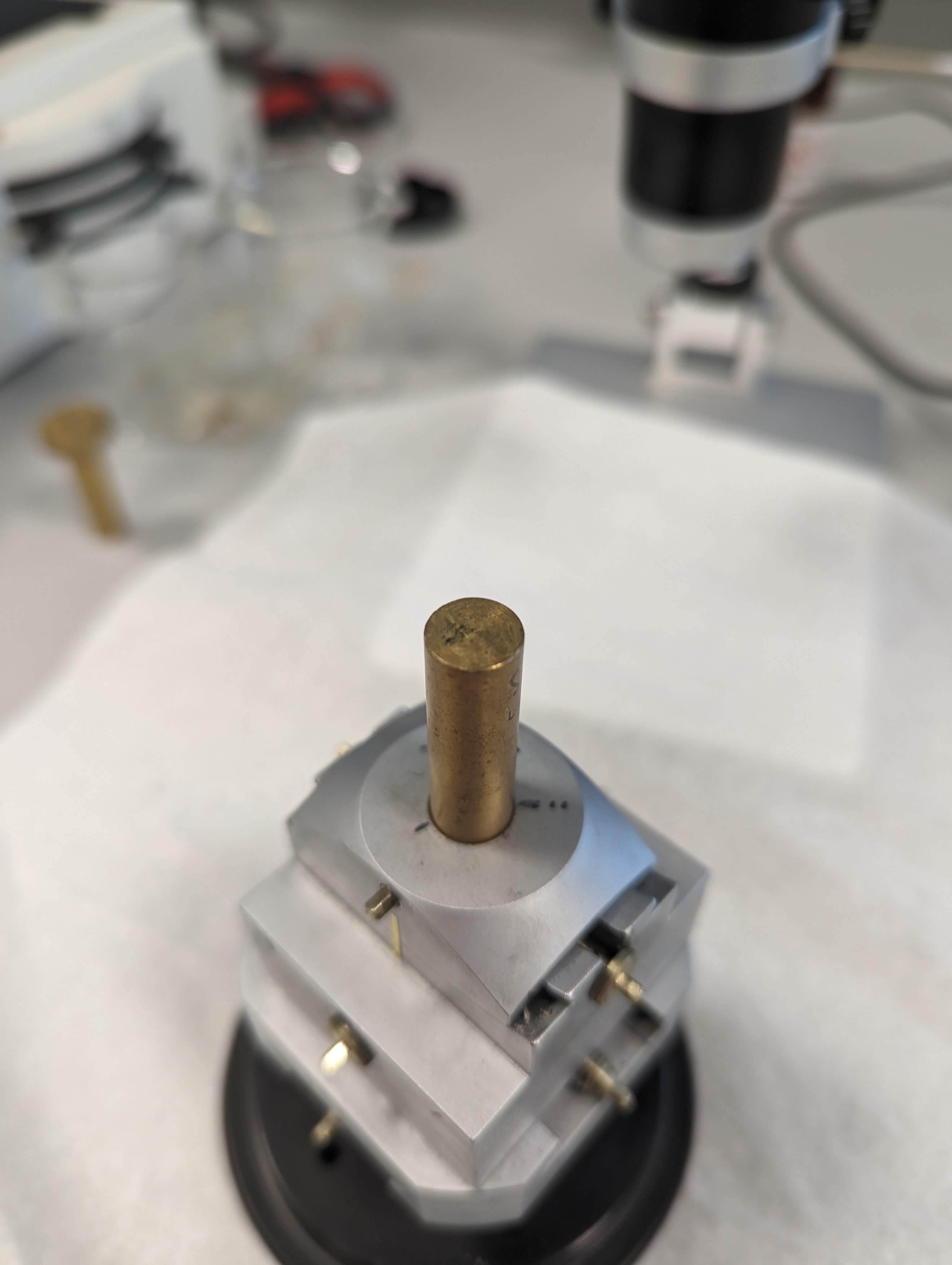

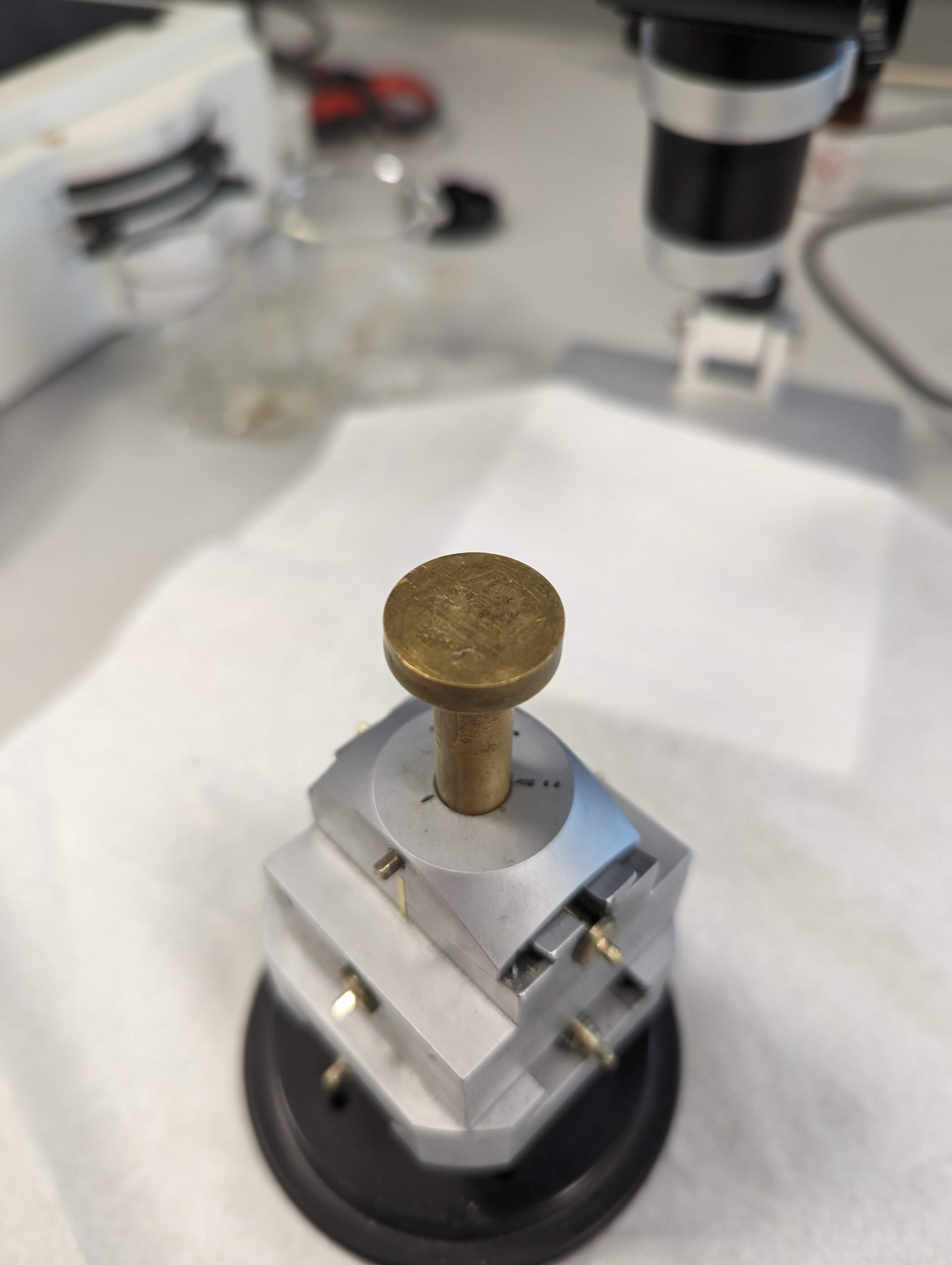

| 9 mm (6/16") |  |

Standard, sits in 4 axis goniometric head with fitting ~9mm. Height from head=38 mm Samples can be adhered to the brass pin using silver paint or carbon tape etc. |

| 20 mm |  |

Large version of the above |

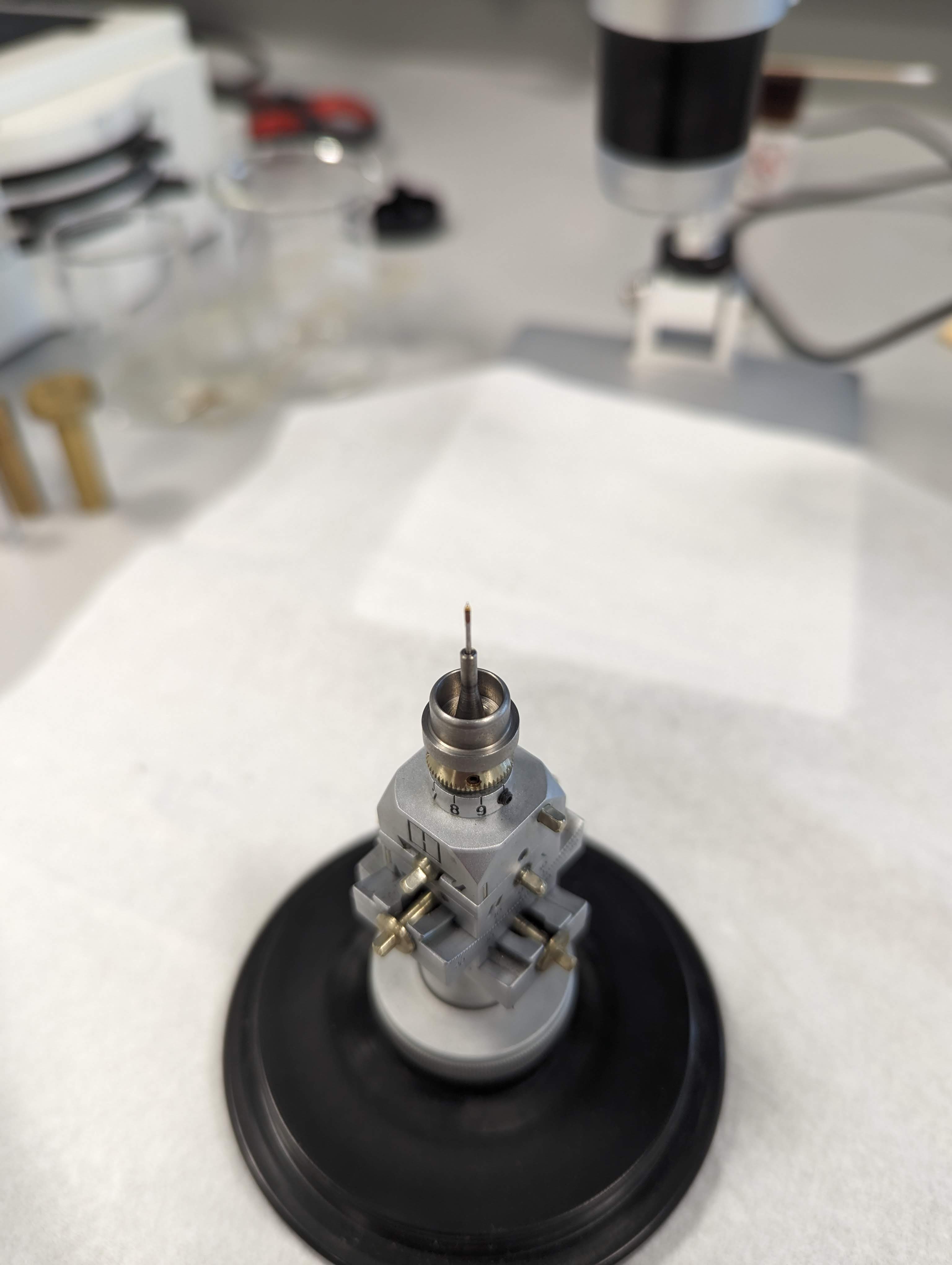

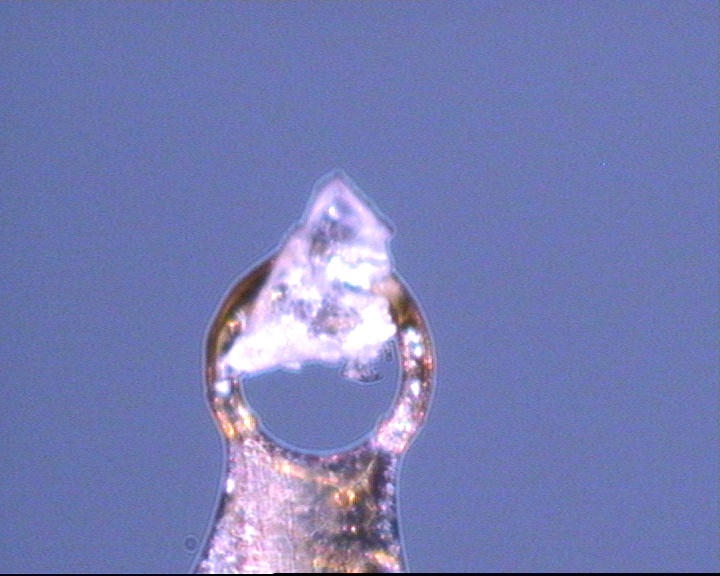

| - |   |

Standard crystallographic magnetic mount for mitegen style pins. |

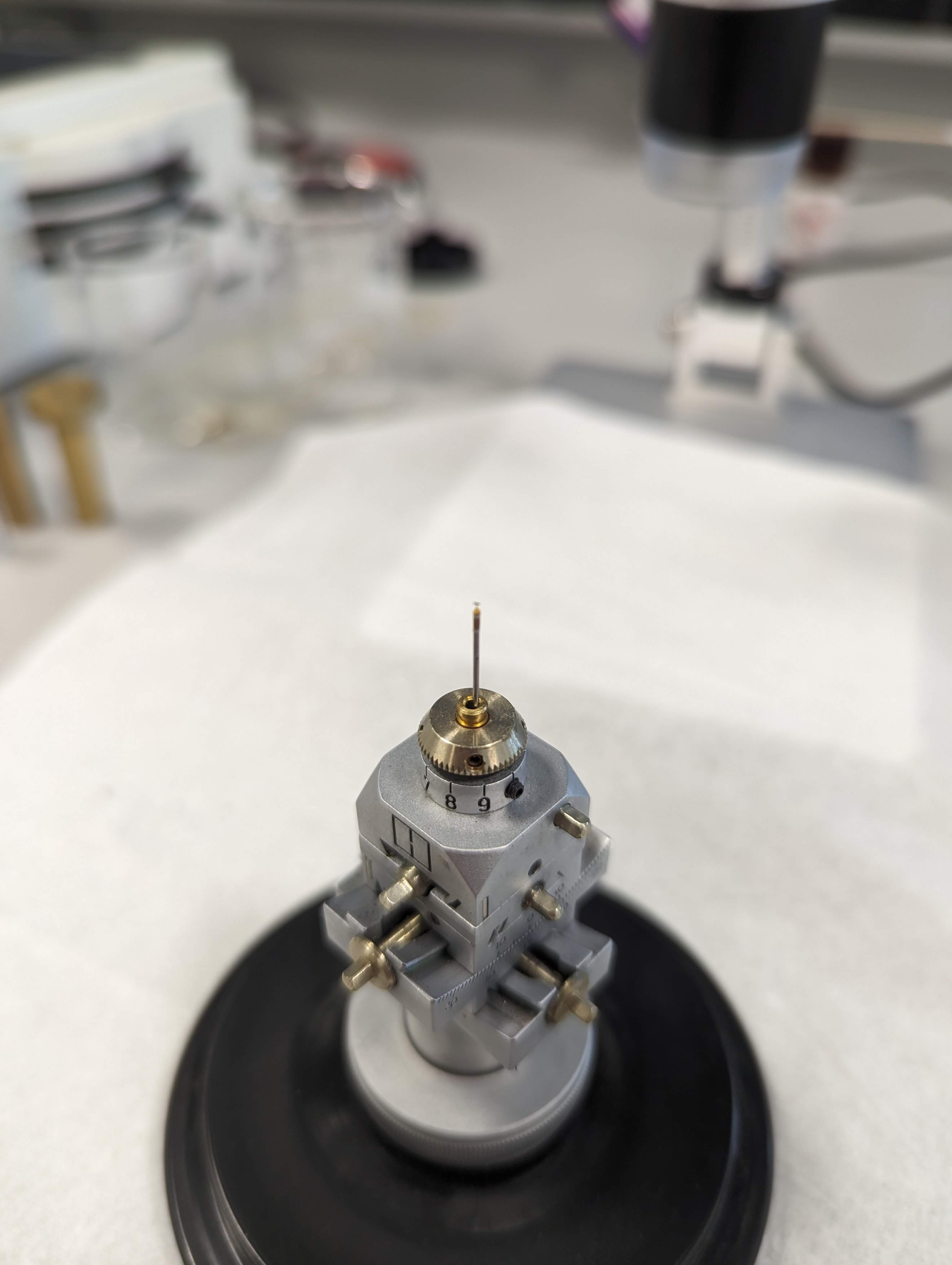

| 3.2 mm |  |

Standard brass pin for mitegen style pins and glass capillaries |

If you have any comments, suggestions or corrections, please contact a member of the beamline staff.

Diamond Light Source is the UK's national synchrotron science facility, located at the Harwell Science and Innovation Campus in Oxfordshire.

Copyright © 2022 Diamond Light Source

Diamond Light Source Ltd

Diamond House

Harwell Science & Innovation Campus

Didcot

Oxfordshire

OX11 0DE

Diamond Light Source® and the Diamond logo are registered trademarks of Diamond Light Source Ltd

Registered in England and Wales at Diamond House, Harwell Science and Innovation Campus, Didcot, Oxfordshire, OX11 0DE, United Kingdom. Company number: 4375679. VAT number: 287 461 957. Economic Operators Registration and Identification (EORI) number: GB287461957003.