Beamline Phone Number:

+44 (0)1235 778905

Principal Beamline Scientist:

Stephen Thompson

Tel: +44 (0)1235 778546

E-mail:

[email protected]

Email: [email protected]

Tel: +44 (0)1235 4494052

The call for proposals for Long Duration Experiments is permanently OPEN

The LDE operates as a “roll-off roll-on” facility.

Due to the number of experiments running and the often long lead time associated with designing, setting up and commissioning long duration experiments, there is no periodic call for proposals.

If you wish to make an enquiry, please contact beamline scientists Prof Chiu Tang and/or Dr. Sarah Day.

Please also refer to the technical information (in the tabs above) and our Application Guidelines.

To complement the existing I11 high resolution and fast time-resolved facilities, the LDE facility opens up new opportunities for those experiments which require weeks to months of periodically monitoring “slow” changes.

It is of particular benefit to research areas where important information on the development of phases over time cannot be obtained via ex-situ methods (e.g. batteries, fuel cells).

Other research areas that will similarly benefit include studies of crystallisation, gas storage, mineral evolution, seasonal effects, thermal and electrical power cycling and corrosion science, etc.

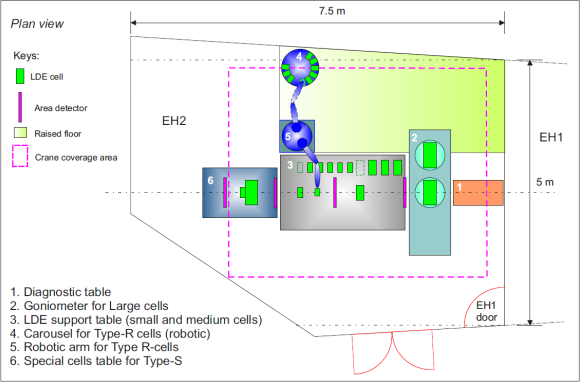

The key instrumental parameters for the LDE upgrade are given below. A large second experimental hutch (EH2) houses the LDE facility and a new larger control room and lab space have been constructed to the side of the beamline.

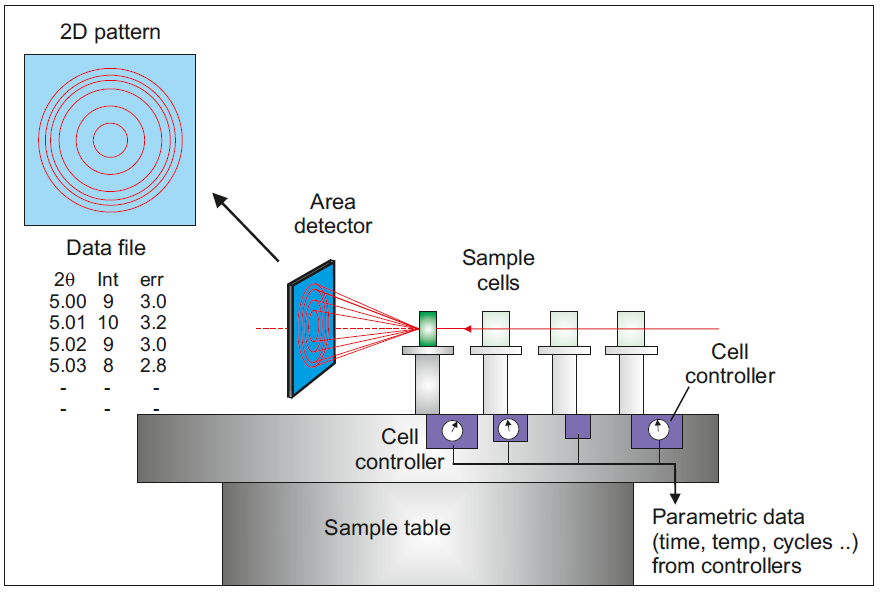

LDEs are mounted on a large sample table equipped with adjustable linear drives, to automatically and periodically move sample cells in and out of the beam. A Pixium area detector is driven by a motorised stage to record diffraction patterns. LDEs are set up and left in place with programmed automated data collections. Sample environments such as cryogenic systems, incubators, heating stages, climate simulators and high pressure gas cells can be accommodated for user operation.

| Energy range: |

25 keV |

| EH2 size: | ~5 x 8 m |

| Beam size: | 400 um2 |

| Photon flux: | ~1013 phs/s/0.1% at 25 keV |

| Detector: | Pixel area detector, active area of 420x420 mm2 or bigger, pixel size = 200 um or less, speed = minutes – ms per frame (pattern) |

Schematic layout of the new hutches and control cabins

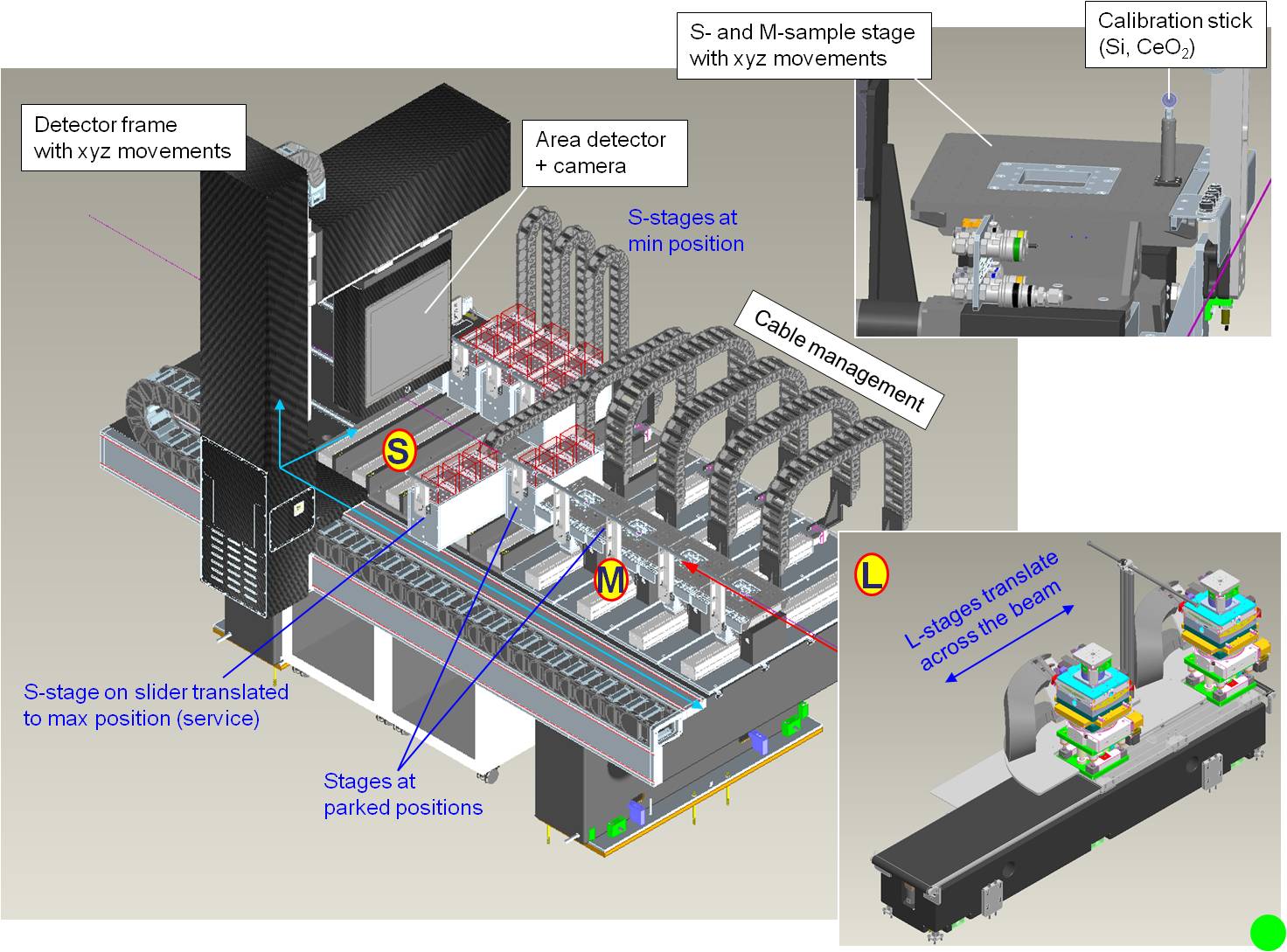

Schematic layout of experimental components and equipment in EH2

We define five groups of sample cells or environments:

(i) Small cells with services (electrical, water and/or other coolants). These are small scale environments which could have heating, cooling, liquid circulation or electrical cycling to study long term effects of materials subjected to these conditions, e.g. seasonal changes, solution crystallisation and charged/discharged battery materials.

(ii) Medium cells with services (electrical, water and/or other coolants). Their functions are very similar to the small cells, but have a larger capacity to handle more material, or allow space or more services.

(iii) Large cells with services (electrical, water and/or other coolants). These are heavy duty systems to simulate industrial conditions, e.g. alloy degradation under tension and humidity effect in pharmaceuticals in large volume storage. Each sample environment should be placed on a goniometer (heavy duty) to be manipulated into position.

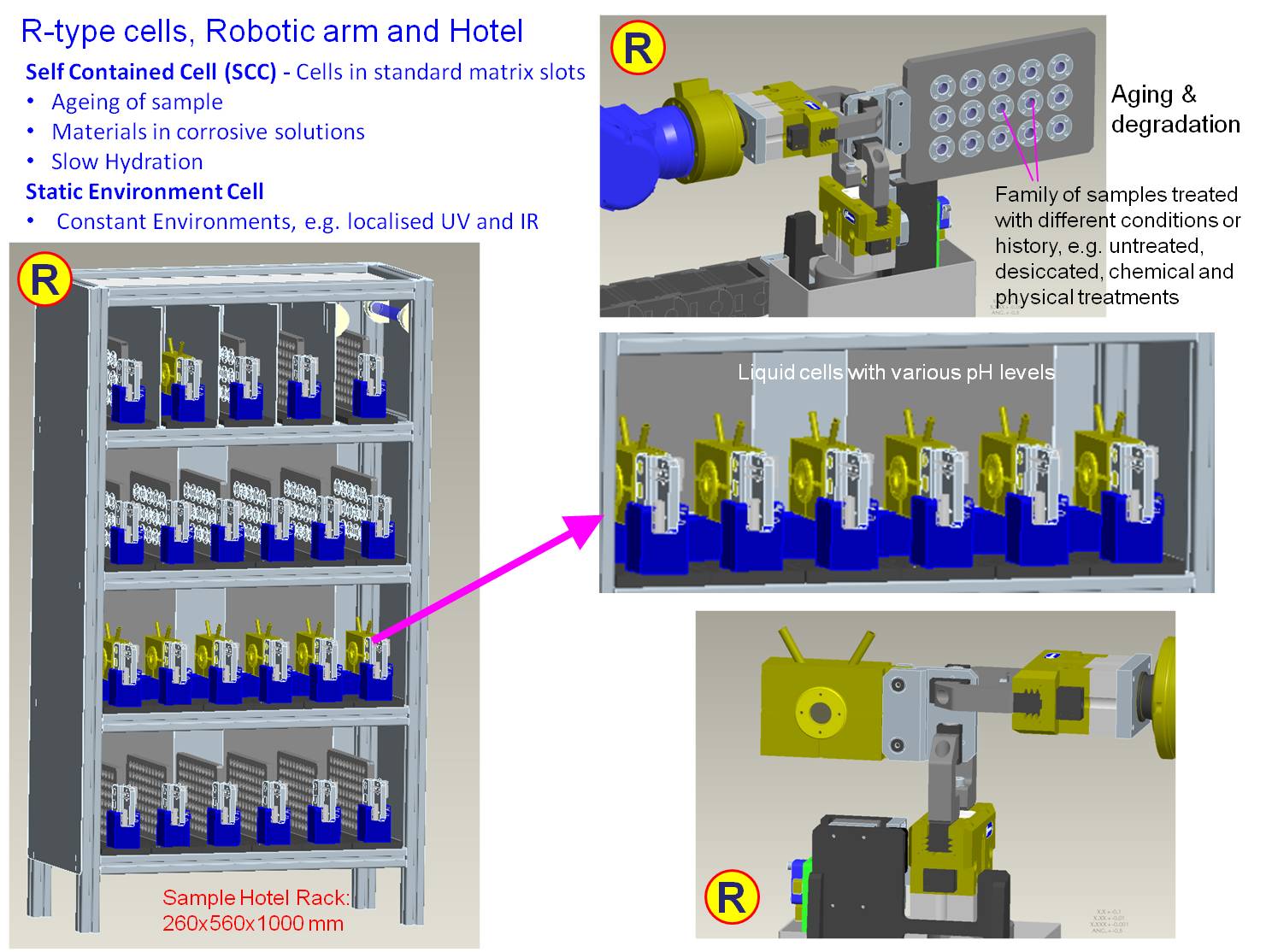

(iv) Small cells (Type-R) are cells with the size module defined in 1, but without the service requirement. These will be stored on a carousel or shelves and designed with a locating pin for pick/place by robotic arm. These are for self contained systems such as slow chemical reactions, corrosion or the aging of materials such as pharmaceuticals and biofuels.

(v) Special cells (Type-S) are those that do not fit to any of the above specifications and will be treated as special cases to be dealt with individually. A platform with sufficient room will be set aside to accommodate one or two such cells.

The dimensions and other specifications for these classes are summarised in the table below. The classification of an individual cell is important, allowing its assignment to a particular platform or stage stated in the table and above figure.

Summary of LDE sample cell classification.

| Class |

Cell dimensions (mm) |

Weight (kg) |

Services* required | Platform, stage | No. of bases |

| (i) Small cell | ≤ 100x100x50 |

≤ 2 |

yes | Large sample table (3) |

6 |

| (ii) Medium cell |

≥ 100x100x50 ≤ 300x300x150 |

≥ 2 ≤ 5 |

yes | Large sample table (3) |

4 |

| (iii) Large cell |

≥ 300x300x150 ≤ 500x500x300 |

≥ 5 ≤ 30 |

yes | Heavy-duty goniometer (2) |

2 |

| (iv) Type-R | ≤ 100x100x50 |

≤ 2 |

No (robotic) |

Carousel/ shelf (4,5) |

10 |

| (v) Type-S | TBD (user) |

TBD |

TBD | TBD (6) |

TBD |

* Services include electricity, gases, water and/or other coolants, etc.

Technical drawing of the LDE End Station highlighting the locations of the large (L), medium (M) and small (S) sample cells

Technical drawing of the sample hotel, where small cells will be stored when not being studied on the beamline

Schematic of the LDE Hutch during experiments

Diamond Light Source is the UK's national synchrotron science facility, located at the Harwell Science and Innovation Campus in Oxfordshire.

Copyright © 2022 Diamond Light Source

Diamond Light Source Ltd

Diamond House

Harwell Science & Innovation Campus

Didcot

Oxfordshire

OX11 0DE

Diamond Light Source® and the Diamond logo are registered trademarks of Diamond Light Source Ltd

Registered in England and Wales at Diamond House, Harwell Science and Innovation Campus, Didcot, Oxfordshire, OX11 0DE, United Kingdom. Company number: 4375679. VAT number: 287 461 957. Economic Operators Registration and Identification (EORI) number: GB287461957003.