Cavities, or radiofrequency (RF) cavities, as they are known, produce an electromagnetic field. This field interacts with the electrons in the synchrotron to accelerate them to have exactly the right amount of energy to produce the Diamond X-ray beam. The cavities are tuned to a specific frequency so that electrons always pass through at the same phase and gain the same amount of energy as they lose traveling around the storage ring.

Historically, Diamond has used Superconducting Cavities to do this. Superconducting Cavities allow electric currents to flow with almost no resistance. This is important as electrical resistance produces heat which is unused in synchrotron radiation and amounts to wasted energy.

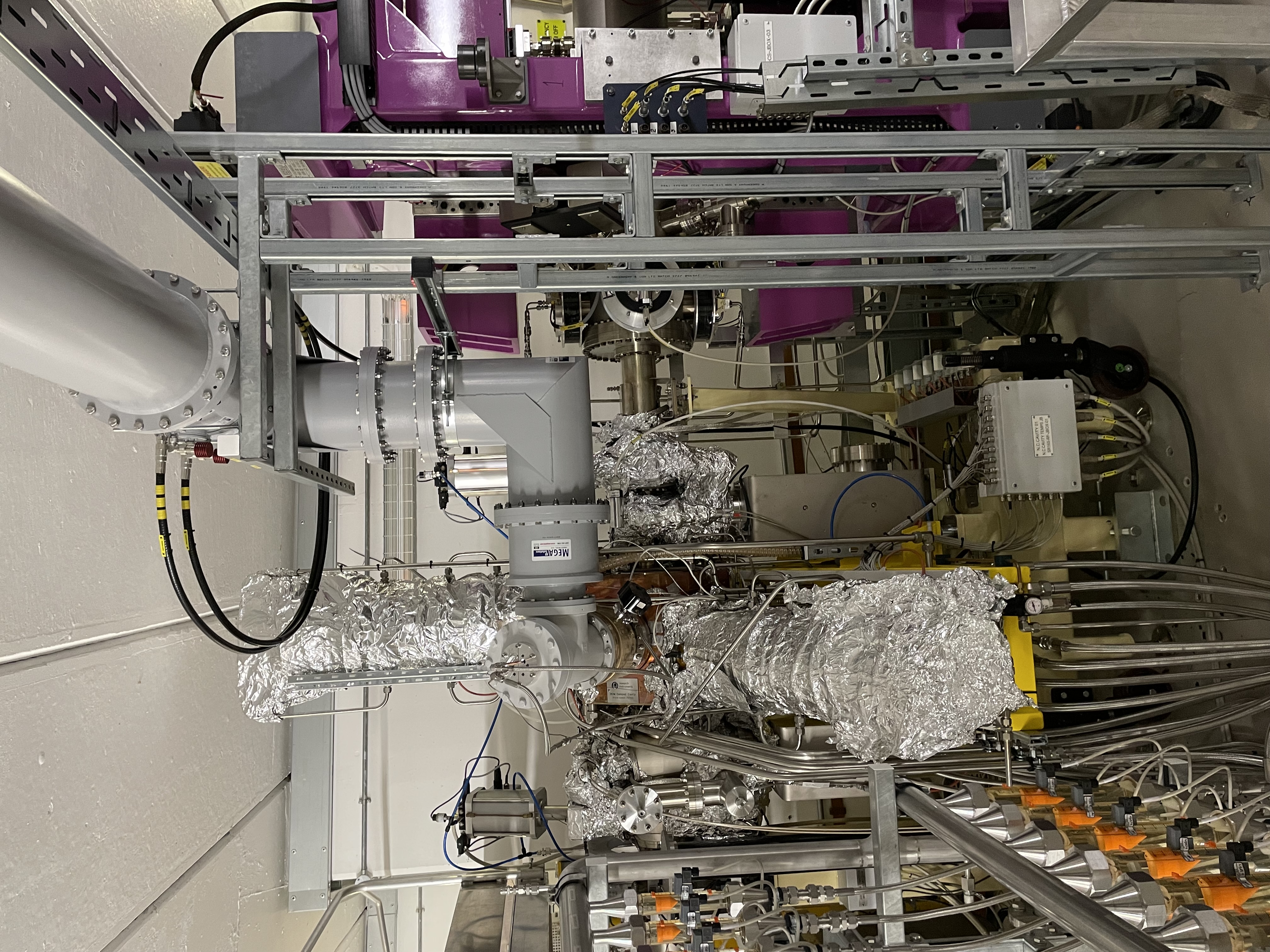

However, superconducting cavities are not without their drawbacks. Firstly, these cavities have to be cooled to near absolute zero in large liquid helium cryostats. This makes the cavity assemblies big and reduces the number that can be placed on a storage ring. Fortunately, you don’t need many superconducting cavities to power a synchrotron as they produce a lot of energy.

Despite being efficient and not wasting very much energy to heat, superconducting cavities still require a lot of power which is today provided by inductive output tubes (IOTs). IOTs are linear beam vacuum tubes that can amplify high frequency radio waves. These radio waves are passed to the RF cavities which convert them into the electric fields used to give energy to the electrons.

IOTs in Diamond are the same high-powered vacuum valves as used in TV transmitters around the world. Without the broadcast market, synchrotron research on its own could not support the IOT industry with its relatively low demand.

However, just as vacuum valve electronics died out, IOTs in TV transmitters and synchrotrons are becoming obsolete and have to be replaced. The need to update critical infrastructure at Diamond presents an opportunity to do things differently, so how would you power the Diamond synchrotron if you could start again?

Dr. Chris Christou, project lead from the RF group at Diamond says the answer to improvement is in redundancy. He explains,

Diamond runs on two superconducting cavities, each powered by four IOTs. If one IOT fails, then the superconducting cavity will not work and the beam will be lost. To build redundancy and security, it would be better to have multiple smaller cavities in the ring which are not all needed to deliver the beam.

This desire for redundancy is leading Diamond away from Superconducting Cavities and towards smaller, Normal Conducting Cavities. Without IOTs they also need to be powered in a completely different way and the IOTs will be replaced with solid state amplifiers.

Solid state amplifiers are much smaller than IOTs. If you compare them, an IOT can produce 80 kW of power whereas a single solid state amplifier can produce only 1 kW. However, 120 solid state amplifiers can be combined to produce 120 kW of power. In this configuration, if one amplifier fails, only 1 kW of power is lost and the beam will continue to shine.

Implementing a completely new type of technology represents many technical, logistical and communications challenges. Complete synchronisation across diverse teams from engineering to RF is needed and as Electrical Design Engineer, Nelson Medina-Pereira MIET, noted,

“Often, we don’t speak the same language. RF differs from electrical design which differs from engineering, we have to overcome these communication challenges to make any kind of progress.”

Even with smooth communication, the project was still incredibly complex. The electrical drawings alone were over 100 pages and designs for this project started several years previously. This is something completely new for Diamond and so there were not templates or similar projects to fall back on, everything was new.

The final design required more floor space than was available at Diamond meaning that a mezzanine floor had to be custom built to accommodate the new Solid State Amplifier (SSA). A large penetration also had to be made into the walls of the synchrotron and this required a lot of work by Roy Grant and the engineering team to make sure that cost-effective and well-functioning shielding solution could be found.

Despite these challenges, testing and validation progressed until the point where a new cavity currently sits in the Diamond storage ring.

Its very presence there is a testament to the huge work and cooperation of the teams both within and outside of Diamond. The ability to perform an upgrade like this also gives a glimpse of what Diamond-II will be capable of when it comes online.

Diamond Light Source is the UK's national synchrotron science facility, located at the Harwell Science and Innovation Campus in Oxfordshire.

Copyright © 2022 Diamond Light Source

Diamond Light Source Ltd

Diamond House

Harwell Science & Innovation Campus

Didcot

Oxfordshire

OX11 0DE

Diamond Light Source® and the Diamond logo are registered trademarks of Diamond Light Source Ltd

Registered in England and Wales at Diamond House, Harwell Science and Innovation Campus, Didcot, Oxfordshire, OX11 0DE, United Kingdom. Company number: 4375679. VAT number: 287 461 957. Economic Operators Registration and Identification (EORI) number: GB287461957003.