Magnetic thin films and multilayers form the foundation of many novel device technologies and are key to the operation of practically any computer hard drive memory in use today. Desirable high-speed performance is underpinned by our understanding, and our ability to manipulate the magnetization dynamics in such materials. However, until now, it is common to only measure the average dynamic behaviour. In new research published in Physical Review Letters, scientists reveal for the first time how the magnetization dynamics in multilayered materials can actually vary between the layers hidden below the surface.

Magnetic multilayered materials are typically sandwich-like structures, composed of magnetic layers in combination with non-magnetic spacer layers and layers formed from heavier elements (which exhibit a strong relativistic quantum effect known as the ‘spin-orbit interaction’). By varying the layer thicknesses, the contributions from, and the interactions between the different layers can be tuned to manipulate the overall properties of the material.

The dynamic magnetization behaviour of a material is the way in which scientists describe how the magnetization of the material changes in time. In computing devices, this is particularly important as it underpins the ultimate high-speed performance that has become so desirable in our electronic gadgets. A common technique to measure this dynamic behaviour is ferromagnetic resonance. This works great for measuring the overall properties of a magnetic material, however, information on the contributions from each constituent layer, or insight into the interactions between neighbouring layers, remains unknown. In their recent publication, scientists at Diamond, along with their collaborators at Oxford University and ShanghaiTech University, demonstrate that their multilayered samples contain complex internal dynamics, which can be explained as a phase lag between the magnetization precessions in the different layers. This discovery is surprising and very different from single layered films which do not show any depth dependent effects.

This new insight into the depth dependence of the magnetization dynamics has been made possible due to new developments at Diamond. This advancement has put a novel spin on traditional ferromagnetic resonance measurements using the unique properties of the X-rays from a synchrotron source.

The light at Diamond consists of ultra-short X-ray flashes which occur 500-million times per second. These X-ray pulses were synchronized with the oscillations in the magnetization and reveal a snapshot of the dynamic state of the system. This technique is known as stroboscopic probing and is similar to the way in which fast oscillating or rotating objects appear stationary when viewed under strobe light. By measuring many snapshots at different stages through the dynamic precession, the time evolution of the system can be reconstructed.

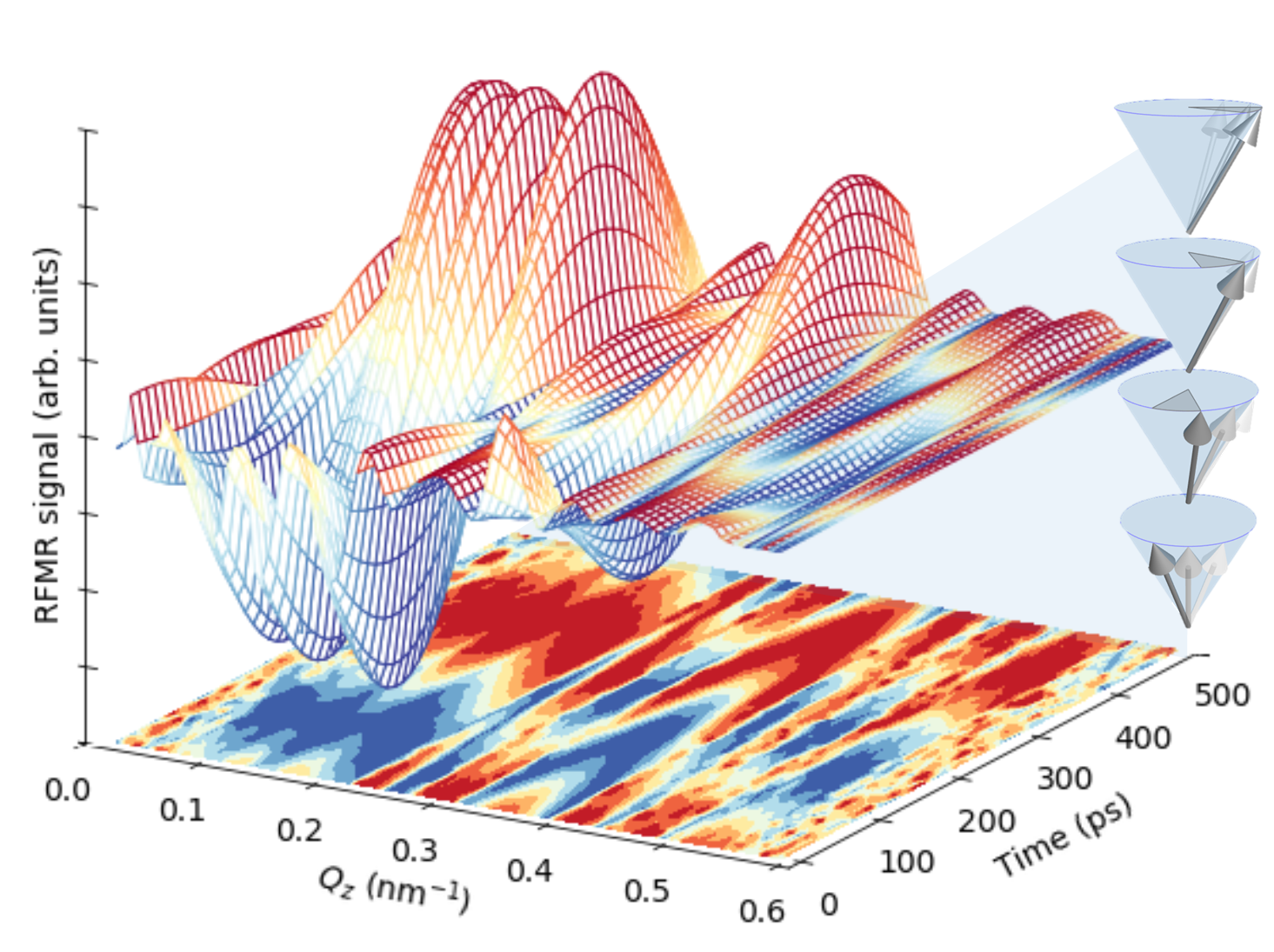

This stroboscopic probe was used in combination with soft X-ray reflectometry measurements in the RASOR scattering chamber on beamline I10. Interference effects occur between the light scattered from different interfaces in a layered system, in a similar way as one can see a rainbow effect in the reflection from a puddle of water covered with an oil film. Careful analysis of this reflectivity is used to reveal the structural depth dependence through the system. By using polarised light, small variations in the reflectometry due to the X-ray magnetic circular dichroism (XMCD) contrast reveal the depth dependence of the magnetization in these systems. The combination of the reflectometry and stroboscopic probing is referred to as reflectometry ferromagnetic resonance (RFMR)

Multilayered magnetic materials are, and will continue to be, the bedrock of novel technological devices for data storage and processing. With the ability to tune the material properties, increasing attention is turning towards generating chiral and multiferroic properties in which ordered magnetic moments can be manipulated with electric or magnetic fields.

With RFMR, the team have developed a key tool with the ability to probe the magnetization dynamics through the depths of layered systems. The ability to reveal insight into the behaviour in the hidden layers is invaluable.

Lead author, Dr David Burn, said:

The ability to measure magnetization changes on picosecond time-scales within the different layers hidden inside a multilayered nanostructure is significant. This is a huge leap forwards and will enable critical developments in future magnetic logic and memory technologies.

With the ability to distinguish how the dynamic behaviour varies through the depth of modern magnetic materials, this technique may pave the way towards exploiting the third dimension of device design in the quest to develop the next generation of high-density and low-energy consumption data processing solutions.

For more information on RFMR, please contact either Dr David M. Burn: [email protected] or Professor Gerrit van der Laan: [email protected].

To find out more about the I10 beamline, or to discuss potential applications, please contact Principal Beamline Scientist Paul Steadman: [email protected]

D. M. Burn, S. L. Zhang, G. Q. Yu, Y. Guang, H. J. Chen, X. P. Qiu, G. van der Laan, and T. Hesjedal. Depth-resolved magnetization dynamics revealed by x-ray reflectometry ferromagnetic resonance. Phys. Rev. Lett. 125, 137201.

See also Physics viewpoint "Shining a Light on Hidden Spin Dynamics" Physics 13, 151 (2020)

Diamond Light Source is the UK's national synchrotron science facility, located at the Harwell Science and Innovation Campus in Oxfordshire.

Copyright © 2022 Diamond Light Source

Diamond Light Source Ltd

Diamond House

Harwell Science & Innovation Campus

Didcot

Oxfordshire

OX11 0DE

Diamond Light Source® and the Diamond logo are registered trademarks of Diamond Light Source Ltd

Registered in England and Wales at Diamond House, Harwell Science and Innovation Campus, Didcot, Oxfordshire, OX11 0DE, United Kingdom. Company number: 4375679. VAT number: 287 461 957. Economic Operators Registration and Identification (EORI) number: GB287461957003.