The University of Manchester museum herbarium was founded in 1860 and contains over a million specimens from all over the world, with collections spanning hundreds of years. The challenge of how to preserve botanical specimens is centuries old, and a wide range of techniques have been used to prevent decay by bacteria, fungi, insects and rodents. The effectiveness of the treatments is demonstrated in the excellent preservation of many museum specimens, but could the pesticides used present a health risk to museum staff?

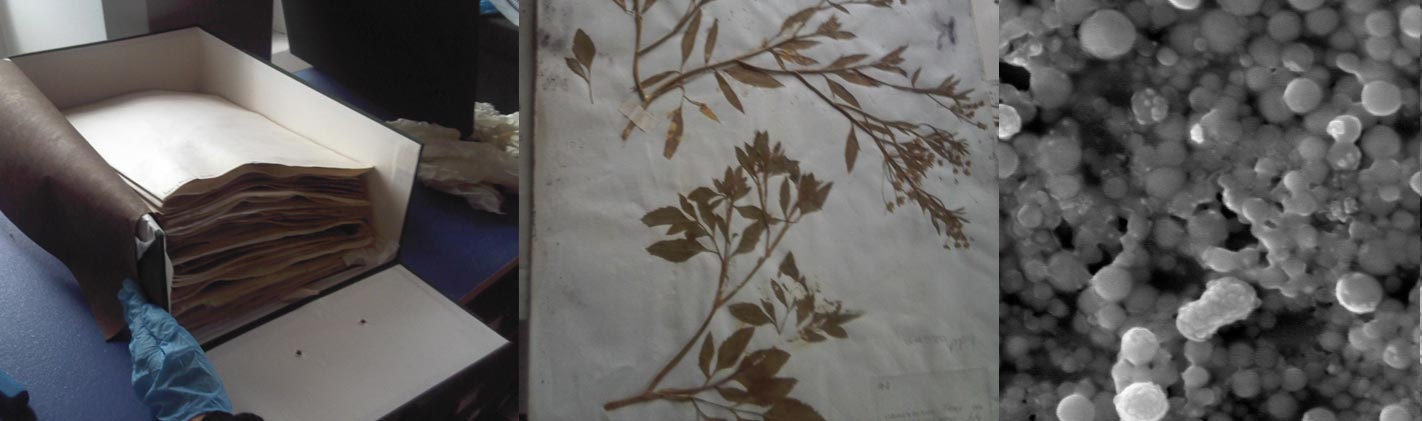

Left to right, Sample specimen box, Hg contaminated specimens and the some of the reacted Se nanoparticles.

Mercury salt solutions have been used to preserve specimens from as early as 1687 right up until to the 1980s. However, for large collections like the University of Manchester museum, where small botanical collections with undocumented histories have been amalgamated, mercury contaminated specimens are unevenly distributed and the concentration is unknown. Potential health risks from these specimens are not confined to those who handle the plants; mercury vapour was seen to be released from the specimen containers whenever they were accessed. A team from the University of Manchester have been using beamline B18 at Diamond Light Source to characterise the mercury in herbarium specimens to identify ways of limiting the release of mercury vapour from contaminated specimen boxes. Their work has been published in the Journal of Hazardous Materials.

The study found that elevated levels of mercury in the museum’s work areas remained well below guideline levels (1.7 µgm-3, compared to guideline levels of 25 µgm-3), but in the actual specimen boxes levels rose to 90 µgm-3. This could present a risk to museum staff accessing specimens from sealed boxes. To try and reduce the concentration, the researchers inserted membrane filters impregnated with biologically derived selenium nanoparticles into the specimen boxes. The samples were then placed in the beamline to understand how the mercury was being trapped, and to identify whether this is a suitable long term solution. What they found was that the selenium efficiently sequestered the mercury vapour, reducing the level by around 47%.

The study found that the contact time between the mercury vapour and the selenium nanoparticles affected the reaction rate, and in fact was most efficient at low gas flow rates, similar to the low level continuous release expected in the specimen boxes. This process therefore seems to present a safe mechanism for limiting the release of mercury vapour from sealed specimen boxes into the atmosphere. Jon Fellowes from the University of Manchester was the lead author on the paper.

“Our research showed that the selenium nanoparticles effectively captured the Hg0v, forming stable HgSe on the surface of the nanoparticles. This presents a promising new way to capture mercury vapour from within contaminated specimen boxes, reducing the risk to museum staff. The Diamond synchrotron provided information on the Hg species that was not obtainable by other methods. The potential to use biogenic Se nanospheres that are formed as a byproduct of biological treatment of selenium contaminated wastewater provides an opportunity to link bioremediation strategies to the production of new nanomaterials for environmental protection.”Jon Fellowes, University of Manchester

Use of biogenic and abiotic elemental selenium nanospheres to sequester elemental mercury released from mercury contaminated museum specimens, JW Fellowes,Richard Pattrick,DI Green,Andrew Dent,JR Lloyd,Carolyn Pearce, JOURNAL OF HAZARDOUS MATERIALS 189 DOI: 10.1016/j.jhazmat.2011.01.079

Diamond Light Source is the UK's national synchrotron science facility, located at the Harwell Science and Innovation Campus in Oxfordshire.

Copyright © 2022 Diamond Light Source

Diamond Light Source Ltd

Diamond House

Harwell Science & Innovation Campus

Didcot

Oxfordshire

OX11 0DE

Diamond Light Source® and the Diamond logo are registered trademarks of Diamond Light Source Ltd

Registered in England and Wales at Diamond House, Harwell Science and Innovation Campus, Didcot, Oxfordshire, OX11 0DE, United Kingdom. Company number: 4375679. VAT number: 287 461 957. Economic Operators Registration and Identification (EORI) number: GB287461957003.