Keep up to date with the latest research and developments from Diamond. Sign up for news on our scientific output, facility updates and plans for the future.

The Engineering and Environment village currently operates four beamlines – the High Resolution Powder Diffraction beamline (I11), the Joint Engineering, Environmental and Processing beamline (I12) also known as JEEP, the Extreme Conditions beamline (I15) and the beamline for X-Ray Pair Distribution Function (XPDF) studies (I15-1). The village’s beamlines all use X-ray diffraction with different sample environments to provide users with a way to study a diverse set of samples under a variety of conditions. A fifth beamline for the village, the Dual Imaging and Diffraction (DIAD) beamline, is in its planning and construction stage and is due to come online in 2020.

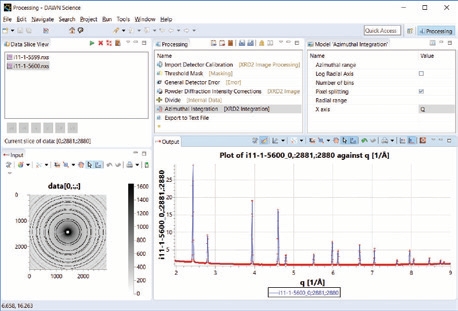

The village’s four beamlines are very distinct and together support a wide range of scientific studies which in 2016 led to more than 140 published papers. The last year has also seen the village driving the upgrade of the existing 'DAWN' software. The new software packages within 'DAWN ' now allow for the calibration and processing of powder X-ray diffraction and small-angle X-ray scattering data1. It provides users with processing and visualisation tools as well as a command-line and scripting interface for on-the-fly processing and the incorporation of complex data treatment tasks. The software is currently being rolled out across Diamond.

I11 supports high resolution and time-resolved powder diffraction studies giving users the ability to probe a sample’s structural properties and behaviour. The instrument in the first experimental hutch continued to operate reliably over the last year hosting more than 50 user experiments, not including rapid access and industrial applications. It has delivered quality science by producing many high impact publications across a range of sciences. The highlight of last year’s development was the robotic sample changer which has been upgraded to accommodate more capillary samples as well as a barcode reader for automated sample identification.

I11’s second end station focuses on long-duration experiments. These experiments can run for up to two years, with data being collected weekly. There are now more than 10 such experiments running and the design and technical features of this facility have recently been published2.

I12 (JEEP) offers users the chance to study 'real life engineering' samples. Thanks to the energy of the X-rays used by this beamline - between 50 keV and 150 keV - they are able to penetrate through samples of considerable thickness, rendering subsets of samples unnecessary. The beamline offers both imaging and X-ray diffraction techniques and supports a wide range of science including studies in chemical and material processing. This year has seen time-resolved tomography become a core technique for I12 and using this capability its first publication3. Users have benefitted, not just from the gain in speed but also from in-house research in removing systematic errors in tomographic reconstruction which lead to artefacts4,5. Another new technique on I12 is stroboscopic Energy Dispersive X-ray Diffraction (EDXD). It is used to study structural changes via diffraction during a fast periodic process when a single acquisition would not record sufficient signal. The method combines the advantage of static EDXD to define a 3D-gauge volume with the almost noise-free signal recorded by the high-purity Ge-detectors available at the beamline6.

Figure 1: View of the new DAWN software package which carries out the calibration and processing of powder X-ray diffraction and small-angle X-ray scattering data.

I15 is a diffraction beamline for samples under extreme pressure and temperature conditions. It can support studies of up to several megabar in pressure and thousands of degrees in temperature. Like JEEP it also uses high energy X-rays, ranging from 20 to 80 keV, and supports powder- and single-crystal diffraction techniques. The beamline offers users a range of pressure cells for experiments, including assistance with gas loading. This year this service has been in high demand, mainly by users studying samples at pressures below several kbar. Throughout the past year, beamline staff have been optimising the second end station, specifically the micro-focussing mirror and the laser-heating system setups. X-rays with focal spot sizes of the order of 5 μm x 8 μm can now be used for laser-heating studies in the multi-megabar pressure regime.

I15-1, the new XPDF beamline, is now working in harmony and pseudo independently with its parent beamline, I15. The last X-ray component, the 1 m long multi-layer bimorph mirror to provide vertical focussing, was installed in September 2016 and XPDF welcomed its first users in April 2016. Since then, the beamline has been undergoing a thorough commissioning of the beamline hardware and software. A variety of commissioning user experiments have been performed covering a diverse range of scientific fields. This has led to the first XPDF publication in September 20167. The first user call has been issued and peer-reviewed experiments started in April 2017.

The ambitious XPDF-software project has involved significant effort from the Scientific Software, Data Acquisition and Controls groups. It will transform the beamline into a dedicated XPDF beamline that will ultimately provide data collection, processing and analysis software to allow non-expert users to use this valuable technique. Alongside this project, emphasis will be put on the development of more advanced and diverse sample environments, e.g. devices providing access beyond the existing 100-1000 K temperature range, gas-flow cells and equipment for in situ electrochemical measurements.

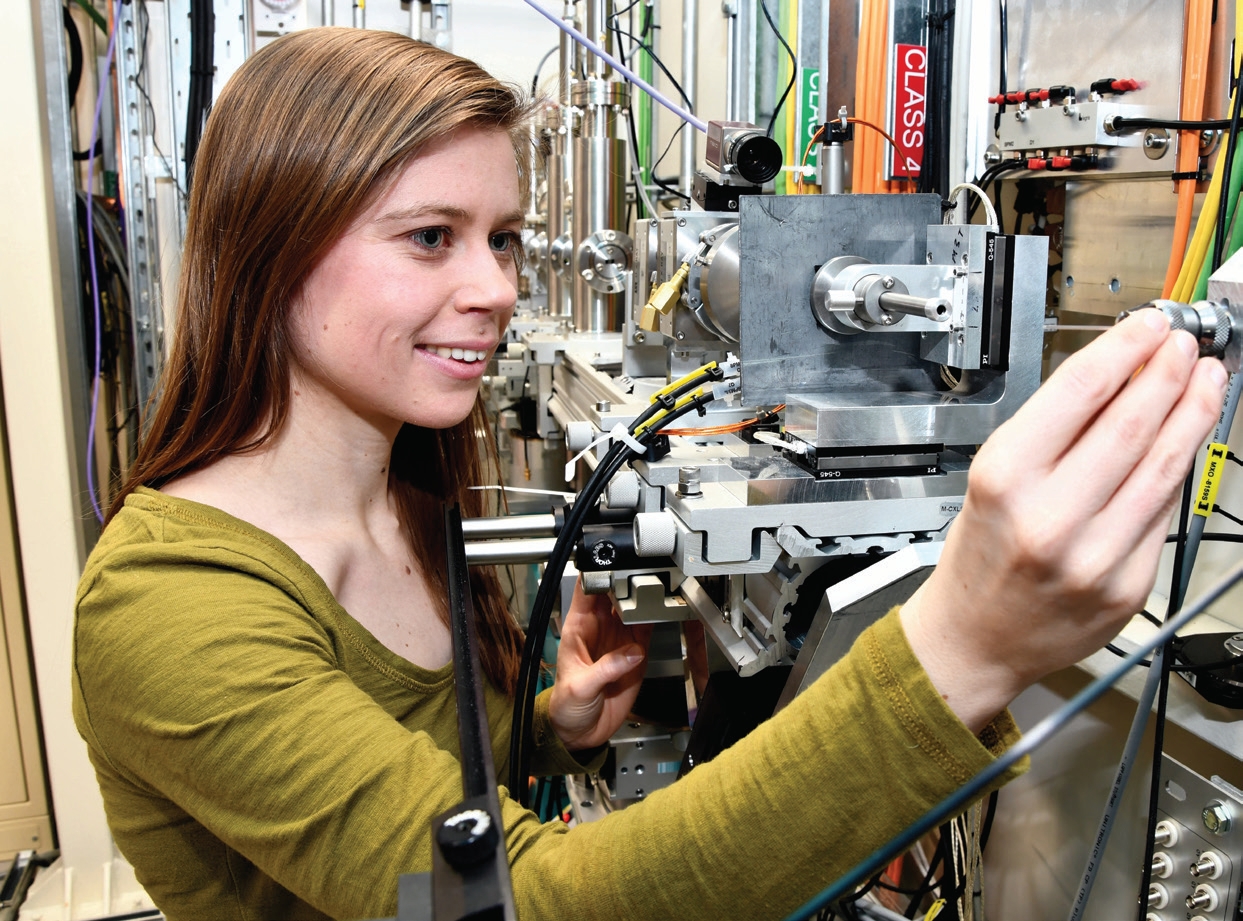

Figure 3: Senior Support Scientist for DIAD, Phoebe Allan, changess the sample for a commissioning experiment on I15-1.

DIAD, which has benefited from a financial contribution from University of Birmingham, is the village's final beamline. It will be the first to offer imaging and diffraction synchronously with an interlacing period of 20 Hz. This will enable in situ structural characterisation experiments that can take advantage of both techniques simultaneously. DIAD’s concurrent wide field imaging and local diffraction will open up a multitude of applications in the research fields such as biomaterials, biological imaging, geological applications, energy and electrochemistry engineering and material science. DIAD began construction in 2016 and the first users are planned for early 2020.

Figure 2: Tobias Warmbier welding sections of the DIAD experimental hutch.

References:

Diamond Light Source is the UK's national synchrotron science facility, located at the Harwell Science and Innovation Campus in Oxfordshire.

Copyright © 2022 Diamond Light Source

Diamond Light Source Ltd

Diamond House

Harwell Science & Innovation Campus

Didcot

Oxfordshire

OX11 0DE

Diamond Light Source® and the Diamond logo are registered trademarks of Diamond Light Source Ltd

Registered in England and Wales at Diamond House, Harwell Science and Innovation Campus, Didcot, Oxfordshire, OX11 0DE, United Kingdom. Company number: 4375679. VAT number: 287 461 957. Economic Operators Registration and Identification (EORI) number: GB287461957003.