Keep up to date with the latest research and developments from Diamond. Sign up for news on our scientific output, facility updates and plans for the future.

The Engineering and Environment village currently operates four beamlines – the High Resolution Powder Diffraction beamline (I11), the Joint Engineering, Environmental and Processing beamline (I12) also known as JEEP, the Extreme Conditions beamline (I15) and the beamline for X-Ray Pair Distribution Function (XPDF) studies (I15-1). The village’s beamlines all use X-ray diffraction with different sample environments to provide users with a way to study a diverse set of samples under a variety of conditions. A fifth beamline for the village, the Dual Imaging and Diffraction (DIAD) beamline, is in its planning and construction stage and is due to come online in 2020.

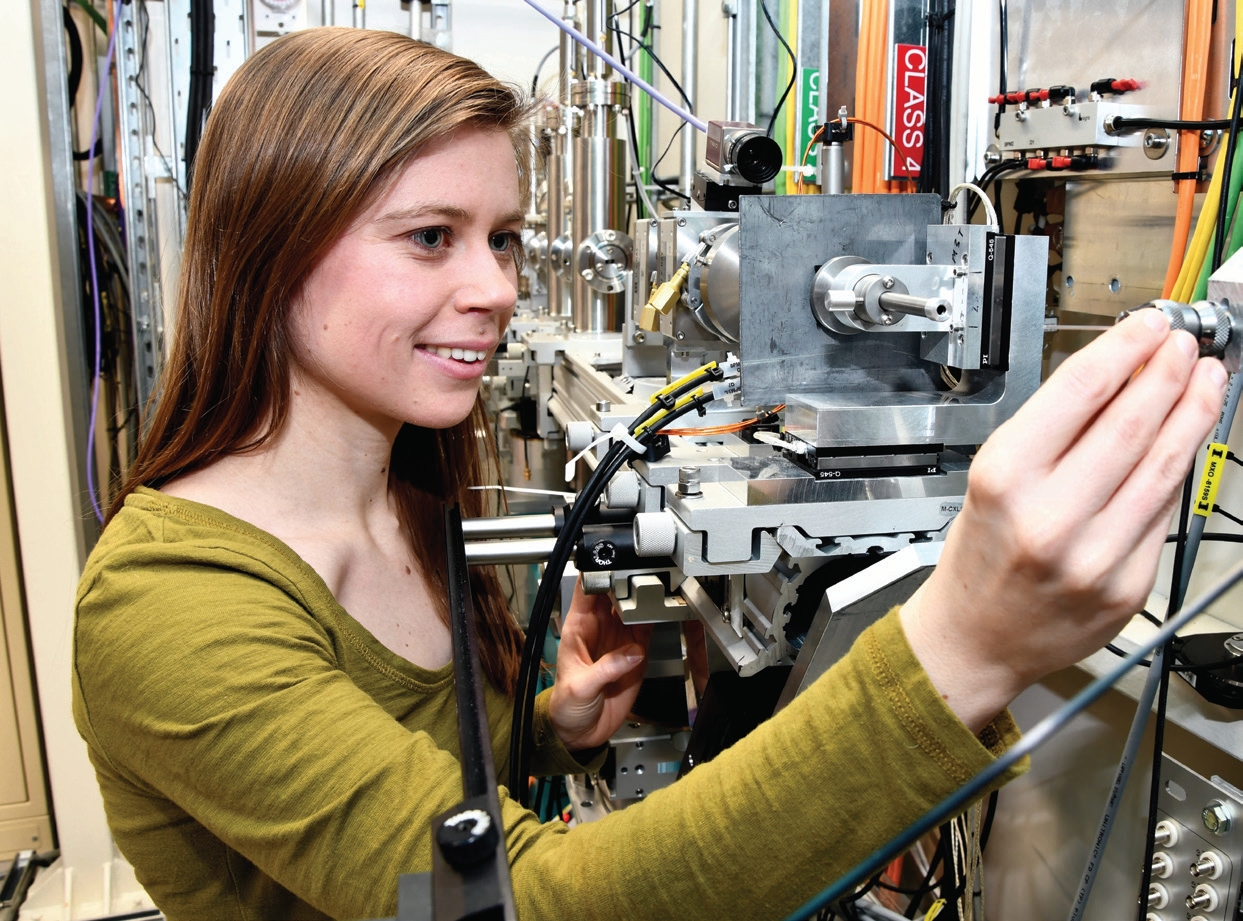

Materials such as seashells, teeth and bones often have remarkable physical properties that are far better than those of equivalent artificially produced substances. These biominerals contain brittle minerals and flexible polymers, and often show highly organised structures. Together, these features combine to give the correct level of strength and durability required for their applications.

Materials such as seashells, teeth and bones often have remarkable physical properties that are far better than those of equivalent artificially produced substances. These biominerals contain brittle minerals and flexible polymers, and often show highly organised structures. Together, these features combine to give the correct level of strength and durability required for their applications.

Read more about this I11 highlights.

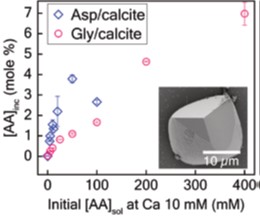

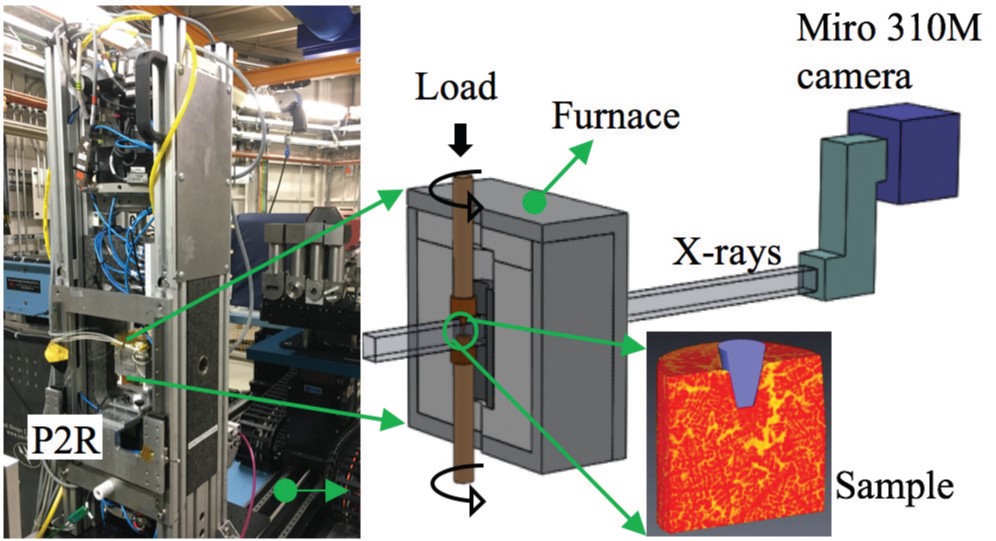

Semi-solid materials – fine mixtures of liquid and solid - are an important class of material that appears in industry and nature. Magma rising in the core of a volcano is often such a mixture, and so is the casting of a semi-solid metal which is used in modern manufacturing techniques. However, their mechanical and chemical behaviour is not understood well enough, limiting the ability to predict the kinetics of volcanic eruptions as well as to improve the design of casting processes. This is particularly the case for granular flow near the melting point, when the material behaves partially as a solid and partially as a liquid. It is known that the nature of this flow can influence the chemistry and microstructure of semi-solid materials, as well as leading to the formation of defects such as damage voids and hot cracking. Diamond Light Source’s Joint Engineering, Environment, and Processing beamline (I12) has revealed, for the first time, how semi-solid materials develop at the microstructural scale as they are deformed.

Semi-solid materials – fine mixtures of liquid and solid - are an important class of material that appears in industry and nature. Magma rising in the core of a volcano is often such a mixture, and so is the casting of a semi-solid metal which is used in modern manufacturing techniques. However, their mechanical and chemical behaviour is not understood well enough, limiting the ability to predict the kinetics of volcanic eruptions as well as to improve the design of casting processes. This is particularly the case for granular flow near the melting point, when the material behaves partially as a solid and partially as a liquid. It is known that the nature of this flow can influence the chemistry and microstructure of semi-solid materials, as well as leading to the formation of defects such as damage voids and hot cracking. Diamond Light Source’s Joint Engineering, Environment, and Processing beamline (I12) has revealed, for the first time, how semi-solid materials develop at the microstructural scale as they are deformed.

Read more about this I12 highlights.

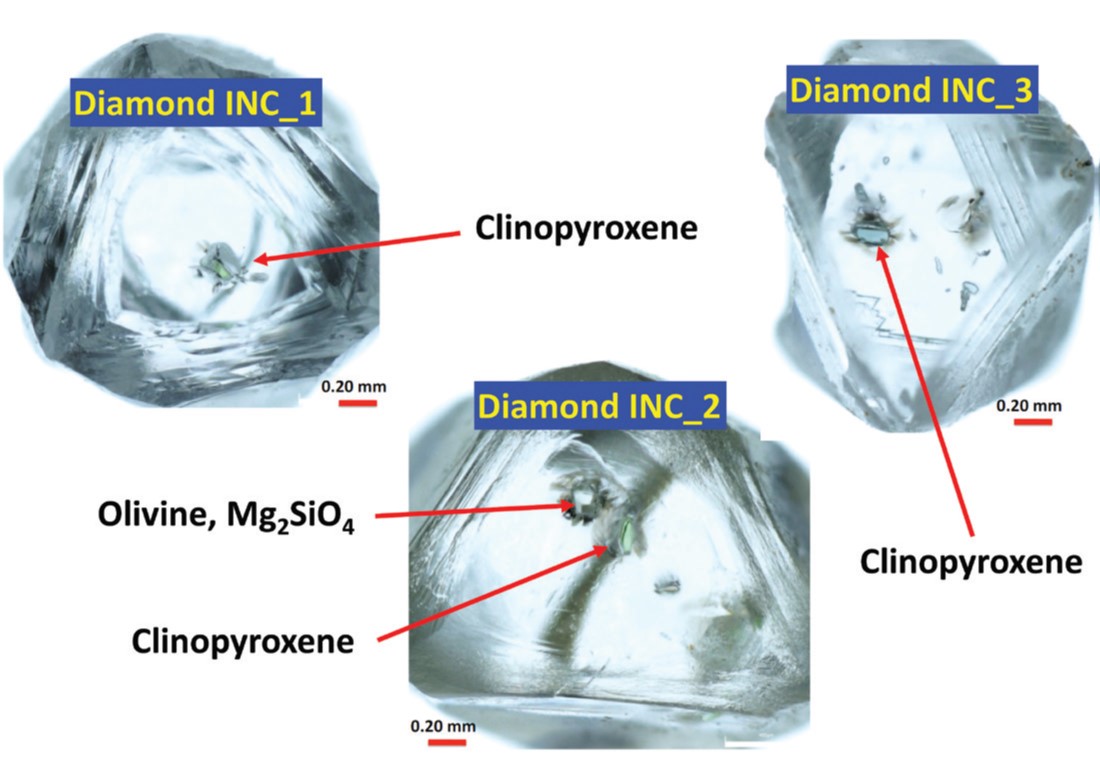

Diamonds are the deepest and oldest terrestrial samples reaching the Earth’s surface after a long journey through the Earth’s mantle. They form between about 120 and 1000 km depth and can incorporate minerals at great depths before bringing them to the surface, allowing us to study directly ”deep fragments of our planet” inaccessible by any other means. Thanks to the study of such fragments we can understand in which type of rocks diamonds were formed and at which depth and temperature within the Earth. However, only 1% of diamonds contain mineral inclusions suitable for scientific investigations and thus a non-destructive approach is very often crucial.

Diamonds are the deepest and oldest terrestrial samples reaching the Earth’s surface after a long journey through the Earth’s mantle. They form between about 120 and 1000 km depth and can incorporate minerals at great depths before bringing them to the surface, allowing us to study directly ”deep fragments of our planet” inaccessible by any other means. Thanks to the study of such fragments we can understand in which type of rocks diamonds were formed and at which depth and temperature within the Earth. However, only 1% of diamonds contain mineral inclusions suitable for scientific investigations and thus a non-destructive approach is very often crucial.

Read more about this I15 highlights.

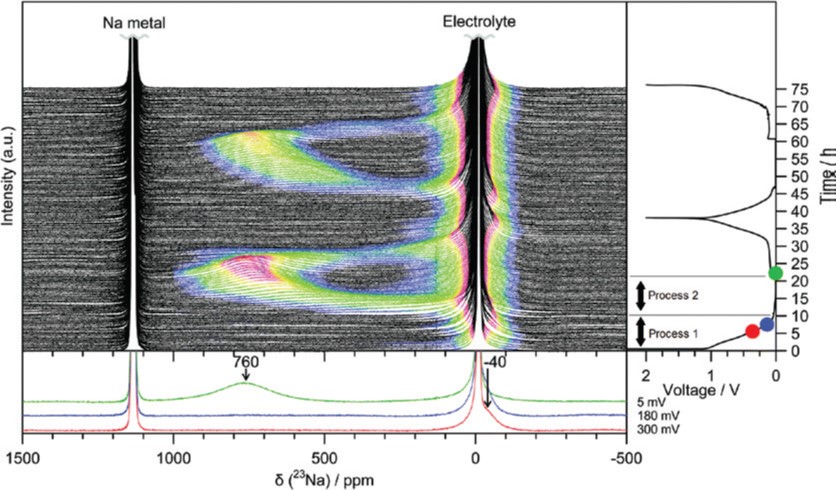

Rechargeable lithium-ion batteries are commonly used in a myriad of electronic devices and even vehicles, but lithium itself is a limited and expensive resource. Sodium-ion batteries are a cost-effective alternative to lithium-ion batteries as sodium is so abundant; however, their implementation is severely hindered by the poor electrochemical performance of current electrodes. 'Hard carbon' is one of the most promising materials to use for sodium-ion anodes, but little is known of the way in which sodium is stored within the carbon.

Rechargeable lithium-ion batteries are commonly used in a myriad of electronic devices and even vehicles, but lithium itself is a limited and expensive resource. Sodium-ion batteries are a cost-effective alternative to lithium-ion batteries as sodium is so abundant; however, their implementation is severely hindered by the poor electrochemical performance of current electrodes. 'Hard carbon' is one of the most promising materials to use for sodium-ion anodes, but little is known of the way in which sodium is stored within the carbon.

Read more about this I15-1 highlights.

Diamond Light Source is the UK's national synchrotron science facility, located at the Harwell Science and Innovation Campus in Oxfordshire.

Copyright © 2022 Diamond Light Source

Diamond Light Source Ltd

Diamond House

Harwell Science & Innovation Campus

Didcot

Oxfordshire

OX11 0DE

Diamond Light Source® and the Diamond logo are registered trademarks of Diamond Light Source Ltd

Registered in England and Wales at Diamond House, Harwell Science and Innovation Campus, Didcot, Oxfordshire, OX11 0DE, United Kingdom. Company number: 4375679. VAT number: 287 461 957. Economic Operators Registration and Identification (EORI) number: GB287461957003.