The synchrotron XAS community, including Industrial Liaison’s Anna Kroner, are all heading to Karlsruhe for XAFS16, the 16th International Conference on X-ray Absorption Fine Structure this week. Organised by the Karlsruhe Institute of Technology in close collaboration with Helmholtz-Institutes DESY (Hamburg) and HZB (Berlin), the triennial conference is dedicated to information exchange and discussion on current research using X-ray Absorption Fine Structure spectroscopy and related methods. The conference provides a forum for the presentation of new scientific results and underlying theoretical approaches and technological developments in XAFS via plenary lectures, invited and contributed talks and posters.

Anna’s talk featured in the Industrial Session at XAFS16 on the topic of “Industrial Research on Catalysis at Diamond Light Source”. Co-authors on her contribution include Miren Agote Aran from the UK Catalysis Hub at the Research Complex at Harwell (RC@H), Andy Beale from University College London and RC@H, Paul Collier from Johnson Matthey and Paul Webb from Sasol. Anna’s presentation highlighted the key role for the Industrial Liaison team in

working with industry partners to gaining a real understanding of customers’ needs and translating this to find the best ways to solve real industrial problems by applying synchrotron-based methodologies. As

catalysis is major area of interest for Diamond’s industrial partners, she was able to provide an overview of the current research activities at Diamond based on our collaborative work with industrial partners in the field of catalysis.

Topics under discussion included the requirements for high selectivity and activity of catalysts; among the most crucial demands for a successful commercial application. Catalyst characterisation therefore provides a unique opportunity for industry to develop new challenging materials for energy, chemistry and environmental technologies. Over the past decades, great efforts have been devoted to developing methods for catalyst characterisation under real operating conditions. In order to facilitate such experiments, the Industrial Liaison team at Diamond has

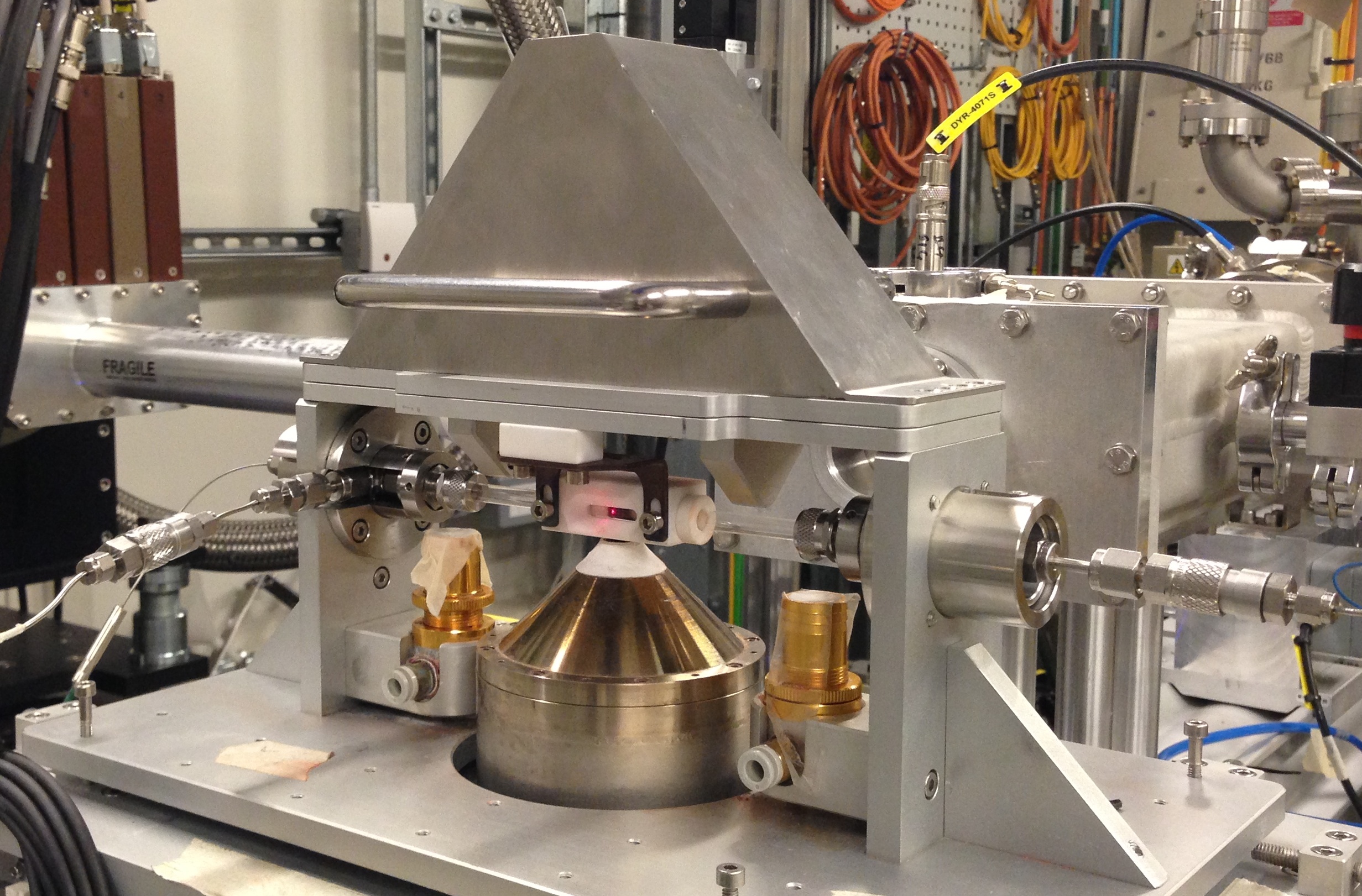

developed a gas flow reactor (picture below) for use on multiple beamlines which Anna described in detail.

The sample environment is a generic capillary-based cell with temperature control and gas mixing/switching capabilities which covers a wide range of catalytic processes. This set-up allows us to mimic operational conditions and, at the same time, gives the flexibility to study structural properties of the catalysts using a wide range of techniques. The reactor has been combined with

X-ray absorption spectroscopy, mass spectrometry, Raman spectroscopy, and

X-ray powder diffraction and has been used by a number of industrial users from around the world.

By increasing our understanding of individual industry sector’s needs, the Industrial Liaison team at Diamond is open for collaboration with industrial partners in various applications. Specific examples of our collaborative work with industrial partners on catalysis research were highlighted during the presentation including a recent collaboration between

Johnson Matthey, UCL and RC@H where we have a joint PhD studentship. The project is focused on the development of new catalytic materials based on Mo containing zeolites that can be efficiently applied in the process of methane dehydroaromatisation (MDA). MDA process is an alternative route to syngas which consist of a non-oxidative reaction using Mo containing zeolites as the catalyst. The MDA converts methane directly into light olefins and aromatics giving hydrogen as a co-product. In spite of the promising activities and selectivity obtained

via this route, the rapid deactivation of the catalyst is a limiting factor for the commercialisation of this process. The goal of the project is therefore to perform catalyst development studies in combination with novel operando (X-ray absorption, emission and scattering) experimental methods to investigate the influence of the zeolite topology and transition metal on selectivity to hydrocarbons and carbon deposits.

Another ongoing collaborative project has been undertaken with

Sasol Technology Ltd working on the Fischer-Tropsch (FT) catalysts.

In situ XAS studies on the FT-based catalysts under

in situ conditions carried out during beamtime on B18 at Diamond have revealed crucial information on the local structure and oxidation state of FT catalysts.

Anna was also able to showcase the results from a series of experiments including

in situ X-ray absorption spectroscopy, high resolution powder diffraction and synchrotron-based infrared microspectroscopy measurements to characterise catalytic materials and membranes as part of the CARENA project.

CAtalytic REactors based on New mAterials (CARENA) is a large EU-funded (FP7) collaborative project to create technologies enabling efficient conversion of light alkanes and CO

2 into higher-value chemicals.

To reduce the dependency of the European community on imported oil, the CARENA project focused on the implementation of catalytic membrane reactors in the European chemical industry. Diamond took the lead role in the project in developing cells for studies of structural properties of catalysts under operating conditions which are now available for all our users.

These examples serve to highlight how collaborative projects between industrial partners and Diamond scientists have contributed significantly to the development of next generation of materials and industrial processes.

If you would like to know more about

catalysis or

XAFS research at Diamond, please do

get in touch and we’d be very happy to help.