___________________________________

Industrial Liaison Group:

Tel: +44 (0) 1235 778797

E-mail: [email protected]

Imaging is defined as "the process of producing an exact picture of something". In the case of synchrotrons, imaging isn't just about seeing what is on the outside of an object, but what is inside of it. Whether it's metals, engineering components, rocks, biological samples or even delicate archaeological samples, X-ray imaging allow us to view what is contained within the sample, at a molecular level.

X-ray imaging allows detailed information to be gathered from below the surface of a material through either full-field imaging, where the whole sample is illuminated, or through scanning, where the beam is focused to a small spot which is scanned across the sample. The high intensity and energy of the synchrotron X-rays we produce here at Diamond make it possible to image a much larger range of materials and sample thicknesses than conventional X-ray sources, and the brilliance of the synchrotron source produces very high resolution images.

These high intensity X-rays also permit very fast measurements for high speed imaging experiments which allow you to look at changes in your sample during real-time, in situ experiments. A technique called X-ray computed tomography can create three dimensional reconstructions of the internal sample volume which makes it possible to view any cross-section of the virtual image at any angle.

The most common imaging technique is called absorption contrast imaging and it is the technique used in hospital X-ray imaging that we are most familiar with. An absorption contrast image is essentially a shadowgraph, the contrast being generated by the different attenuating power of materials in the sample. The small spot size and high intensity of synchrotron X-rays make is possible to carry out absorption contrast imaging in much finer detail than from conventional sources. Combining absorption contrast imaging with other X-ray techniques allows more detailed complementary information to be gathered, as in diffraction enhanced imaging, or recreation of three dimensional objects from two-dimensional scans as in tomography.

X-ray tomography is the construction of a three dimensional image from two dimensional projections taken at different orientations. High energy synchrotron X-rays can penetrate through thicker materials, providing a tool for examining the internal features of a sample in a non-destructive way. The parallel, monochromatic beam enhances the image quality beyond what is possible with laboratory techniques.

Tomography has many applications in the material science, engineering and biomedical fields. It can be used to characterise the internal structure of porous materials such as trabecular bone or metal foams. Tomography can be used to determine the size and shape of cracks and other defects inside components such as aircraft and automotive parts, where unexpected failures could have catastrophic results. Because it is non-destructive, X-ray tomography can be used to study the internal structure of precious and unique objects in archaeology and palaeontology – for example studying ancient insects fossilised in amber.

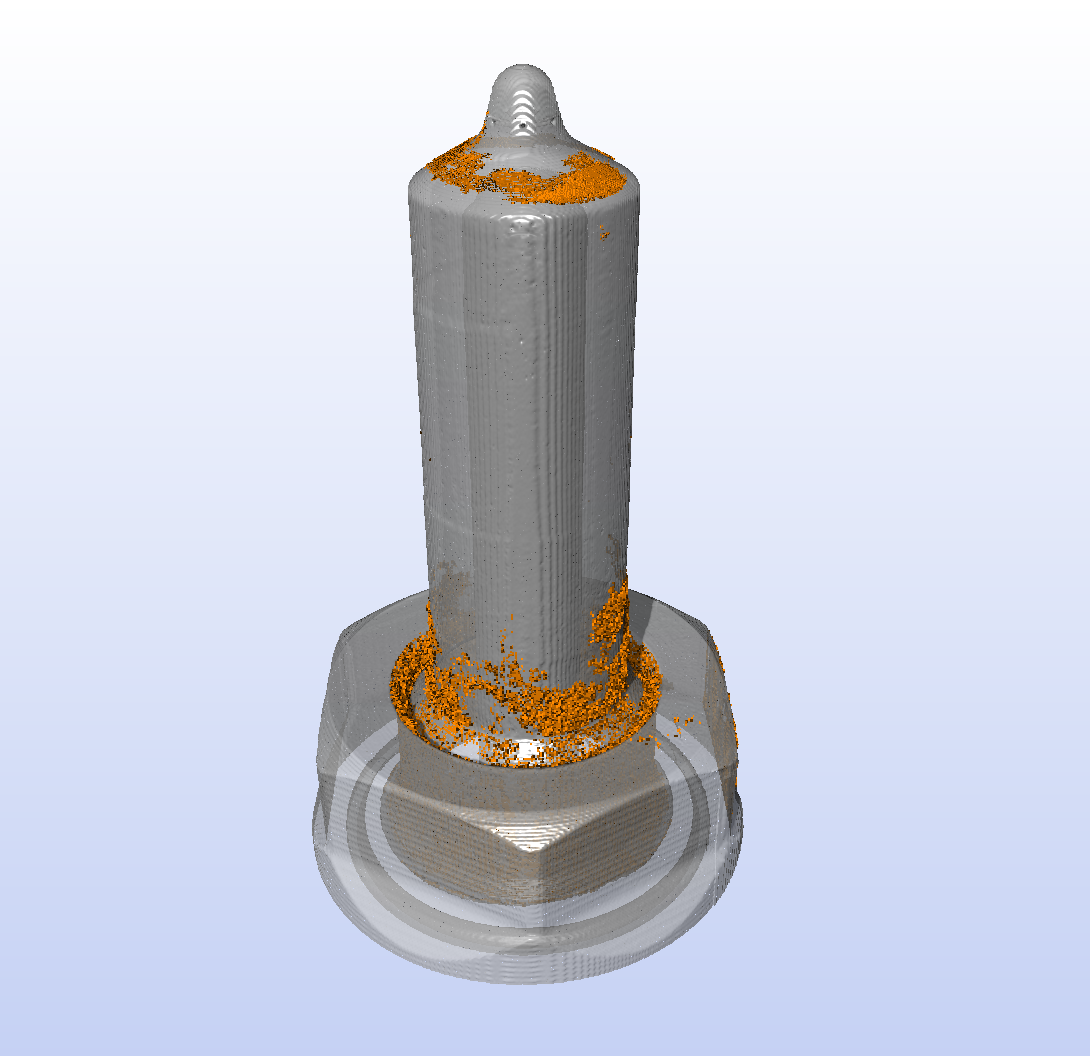

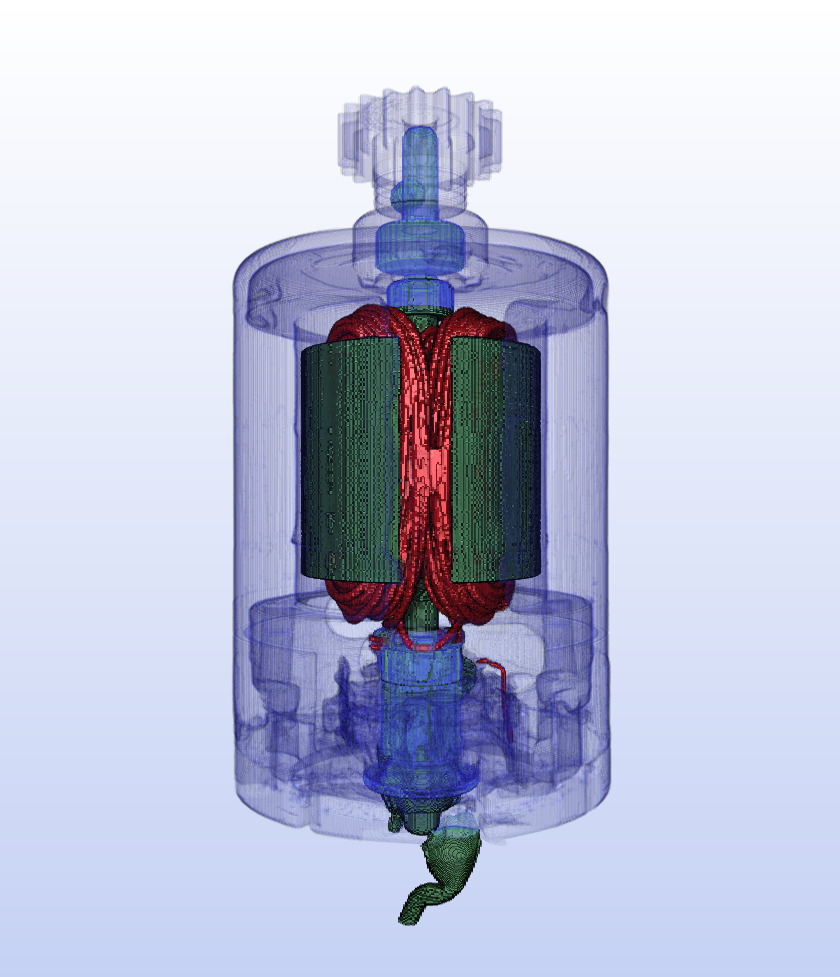

In the diagram below, a fuel injector was imaged at Diamond. The X-ray beam was passed over the sample as it rotated through 180o and 2 dimensional images were collected on a detector. Each of these 2D projection images was then turned into what is known as a Sinogram ( a plot of intensity vs. rotation angle) and it is these sinograms that allow researchers to calculate a Tomogram - a reconstructed cross-sectional slice of the sample.

This is where the 3D picture really starts to build. With a full stack of tomograms, you have a 3D map of the imaged sample, allowing you slice into and view the inside of the sample in any plane. With the 3D reconstruction of the fuel injector, we are able to visualise, measure and analyse the sample components.

Would you like to know more about X-ray imaging and Tomography and how you can apply it to your research? Do you perhaps have a structural problem that you are unable to solve in your lab or a material you wish to find out more about? Then please get in touch with the Industrial Liaison Team at Diamond.

The Industrial Liaison team at Diamond is a group of professional, experienced scientists with a diverse range of expertise, dedicated to helping scientists and researchers from industry access the facilities at Diamond. We’re all specialists in different techniques and have a diverse range of backgrounds so we’re able to provide a multi-disciplinary approach to solving your research problems. We offer a range of services, from full service; a bespoke experimental design, data collection, data analysis and reporting service through to providing facilities for you to conduct your own experiments.

We’re always happy to discuss any enquiries or talk about ways in which access to Diamond’s facilities may be beneficial to your business so please do complete an enquiry form, or give us a call on 01235 778797. You can keep in touch with the latest development by following us on Twitter @DiamondILO or LinkedIn

Diamond Light Source is the UK's national synchrotron science facility, located at the Harwell Science and Innovation Campus in Oxfordshire.

Copyright © 2022 Diamond Light Source

Diamond Light Source Ltd

Diamond House

Harwell Science & Innovation Campus

Didcot

Oxfordshire

OX11 0DE

Diamond Light Source® and the Diamond logo are registered trademarks of Diamond Light Source Ltd

Registered in England and Wales at Diamond House, Harwell Science and Innovation Campus, Didcot, Oxfordshire, OX11 0DE, United Kingdom. Company number: 4375679. VAT number: 287 461 957. Economic Operators Registration and Identification (EORI) number: GB287461957003.