___________________________________

Industrial Liaison Group:

Tel: +44 (0) 1235 778797

E-mail: [email protected]

With the impending deadline to become net zero by 2050, governments across the world are setting out their plans on how to power the ever-increasing demands on energy.

With the impending deadline to become net zero by 2050, governments across the world are setting out their plans on how to power the ever-increasing demands on energy.

Many, like France, have strongly backed plans to build new nuclear reactors, and the UK is likely to follow suit, declaring nuclear power as the key to achieving its targets for clean electricity generation and meeting its net zero target.

But what happens to the waste produced from these reactors?

The UK has already accumulated a whopping 500,000 cubic metres of high and intermediate level nuclear waste since the second world war. With plans to build new reactors in the coming years, this is likely to rise to 750,000 cubic metres.

Most of this waste can, and is, stored in drums at surface level, followed by 5-8 years in a spent fuel pool where radiation levels are able to decay as they are cooled with water; the waste is then transferred to ‘dry cask’ storage. While these measures are effective, they can only be sustained in the short term.

Most of this waste can, and is, stored in drums at surface level, followed by 5-8 years in a spent fuel pool where radiation levels are able to decay as they are cooled with water; the waste is then transferred to ‘dry cask’ storage. While these measures are effective, they can only be sustained in the short term.

Many countries such as Finland and Switzerland have made a head start in addressing this issue, investing in Geological Disposal Facilities (GDFs) which store long-term nuclear waste in metal or concrete containers in vaults hundreds of metres beneath solid rock.

The UK currently uses 30 sites for its surface disposal; it also plans to establish GDFs in key areas of the country; however, this has been met with resistance from local communities who worry about the long-term effects to both the economies of these regions, and the potential harm to the local ecology and human health.

Any repository would have to house nuclear waste for at least 100,000 years so it can decay to safe levels without the risk of human interference or natural events, such as earthquakes or a rise in sea levels that could trigger a leak. That means that any storage materials used must stand the test of time to ensure their integrity.

The use of new, durable materials and the vitrification of nuclear by-products have helped to stabilise nuclear waste; however, stress developed at weld seams during manufacture can cause failures when corrosion occurs, or when casks react with the natural environment e.g. when exposed to sea salt (many UK reactors are close to the sea) and small cracks can occur releasing harmful material and radiation.

The use of new, durable materials and the vitrification of nuclear by-products have helped to stabilise nuclear waste; however, stress developed at weld seams during manufacture can cause failures when corrosion occurs, or when casks react with the natural environment e.g. when exposed to sea salt (many UK reactors are close to the sea) and small cracks can occur releasing harmful material and radiation.

So how can these dangers be mitigated and how can we measure the real long-term effects of nuclear waste?

Only by truly understanding how and why these processes take place can we prevent them occurring. For this we need highly sensitive analytical tools to follow chemical and microstructural processes and gain a deeper insight into the behaviour and performance of the materials used for storage. We also need to replicate the local environment in which they are stored in order to predict any long-term effects.

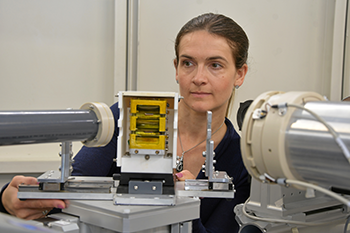

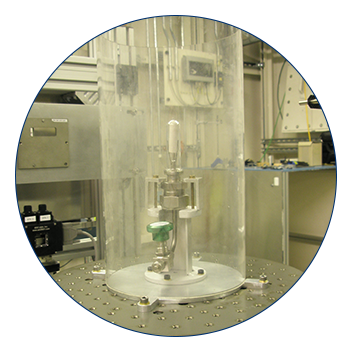

Diamond produces high-brilliance, hard X-rays which allow non-destructive in situ measurements with high spatial and temporal resolution coupled with expert staff to exploit these facilities for maximum benefit across a wide range of projects. Having access to extreme bright light means we can apply a range of advanced characterisation techniques such as X-ray diffraction (XRD), X-ray absorption spectroscopy (XAS), X-ray imaging and small angle X-ray scattering (SAXS) to get a better understanding of the structure and chemistry of radioactive waste materials at the atomic to micrometre scale.

This insight is essential to design effective storage materials that are appropriate for nuclear waste, and to ensure their safe disposal for many years to come.

The key techniques used for this purpose, at Diamond, are:

radionuclides, and to monitor speciation changes that result from changes in their chemical environment.

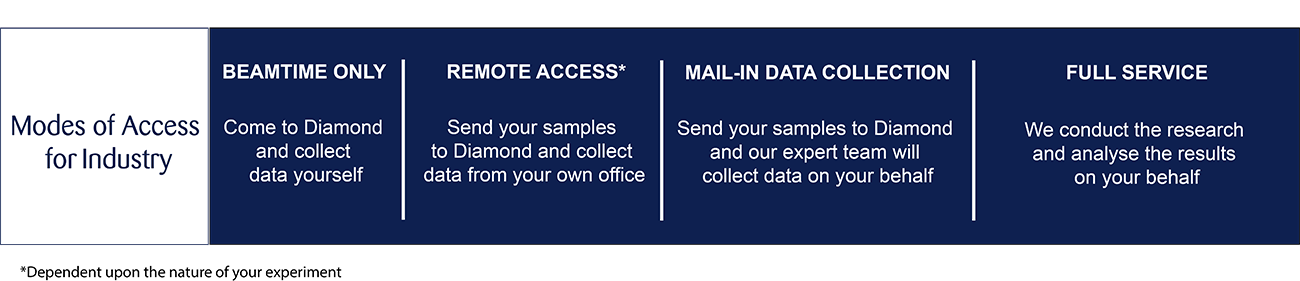

radionuclides, and to monitor speciation changes that result from changes in their chemical environment.Our team of experts provides a wide range of services for commercial users of Diamond - from renting time on our instruments to full-service where we apply the latest tools and expertise to conduct the experiment and analyses (if required) on your behalf.

Each member of the Industry team is an expert in their specific field. They will guide and support you throughout your experiment - as much or as little as you require - and will help you to choose the most effective technique to meet your needs.

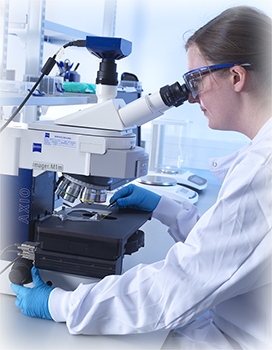

Diamond has supported research into nuclear materials for many years, and now has a dedicated Active Materials laboratory to provide enhanced capabilities and a fully integrated end-to-end resource for experiments related to active materials. Previously we were able to support active experiments on our instruments only; now we are also able to provide on-site facilities for sample preparation and manipulation before, during and after synchrotron experiments.

Diamond has supported research into nuclear materials for many years, and now has a dedicated Active Materials laboratory to provide enhanced capabilities and a fully integrated end-to-end resource for experiments related to active materials. Previously we were able to support active experiments on our instruments only; now we are also able to provide on-site facilities for sample preparation and manipulation before, during and after synchrotron experiments.

Below are some examples of how Diamond’s research facilities have been applied to projects for the nuclear industry:

Nano-scale processes in radwaste management: The most common disposal choice for the long-term treatment of nuclear waste is containment within a deep geological disposal facility (GDF). To remain effective over the long term, the design of a GDF must limit the mobility and migration of radionuclides.

treatment of nuclear waste is containment within a deep geological disposal facility (GDF). To remain effective over the long term, the design of a GDF must limit the mobility and migration of radionuclides.

Using in situ and ex situ X-ray techniques at Diamond, a team of scientists from the University of Manchester were able to study the interaction of radionuclides with geological materials to understand the mechanisms by which radionuclides can become mobile.

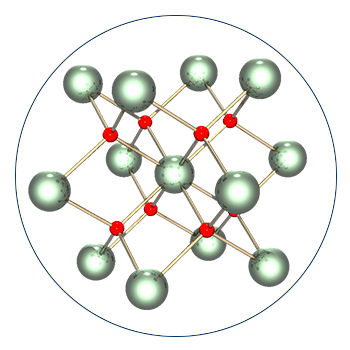

Long term storage of spent nuclear fuels: The predominant component of nuclear fuel is uranium dioxide (UO2), which is insoluble in water. However, the residual radioactivity of the fission daughter products, and of the fuel itself, cause the radiolytic splitting of water into highly oxidising species. These products then cause the dissolution of the fuel with the subsequent release of fission products into the environment. To support modelling efforts, high resolution, surface sensitive and time resolved experimental data were needed to monitor structural changes during the radiolytic dissolution process.

Researchers from the University of Bristol used X-ray diffraction at Diamond to monitor structural changes in single crystal thin films of UO2. These films were exposed simultaneously to pure water and the high intensity incident X-ray beam. The X-rays mimicked the radiation fields found in a spent fuel store, and they probe the surface morphology, oxide layer density and, ultimately, the dissolution of UO2, in real time.

Results from these measurements may help to refine predictive models of the spent fuel/water interface. By investigating the effects of radiation lattice damage and fission product implantation, the group hope to provide a more complete understanding of the corrosion behaviour of spent nuclear fuel.

Non-invasive analysis of ILW containment:

The UK’s intermediate level waste (ILW) is encapsulated in grout and sealed within stainless steel canisters in preparation for interim storage and eventual disposal. Understanding corrosion processes that may occur in these U-containing waste canisters is critical to ensuring the safe long-term containment of this ILW (>100 years).

steel canisters in preparation for interim storage and eventual disposal. Understanding corrosion processes that may occur in these U-containing waste canisters is critical to ensuring the safe long-term containment of this ILW (>100 years).

Researchers from the University of Bristol used a combination of techniques at Diamond to safely observe the evolution of corrosion products of U samples encapsulated in grout. They used non-invasive tomography to image the samples, to identify and locate the products of the corrosion process. Diffraction experiments were conducted to allow the identification of the species present; this technique enabled the group to identify both incidents of UO2 and UH3.

We have a dedicated industry specific team who are specialists in a range of different research techniques. They can guide and support you throughout your research. Please get in touch for further information and to find out how we can support your nuclear research.

Diamond Light Source is the UK's national synchrotron science facility, located at the Harwell Science and Innovation Campus in Oxfordshire.

Copyright © 2022 Diamond Light Source

Diamond Light Source Ltd

Diamond House

Harwell Science & Innovation Campus

Didcot

Oxfordshire

OX11 0DE

Diamond Light Source® and the Diamond logo are registered trademarks of Diamond Light Source Ltd

Registered in England and Wales at Diamond House, Harwell Science and Innovation Campus, Didcot, Oxfordshire, OX11 0DE, United Kingdom. Company number: 4375679. VAT number: 287 461 957. Economic Operators Registration and Identification (EORI) number: GB287461957003.