___________________________________

Industrial Liaison Group:

Tel: +44 (0) 1235 778797

E-mail: [email protected]

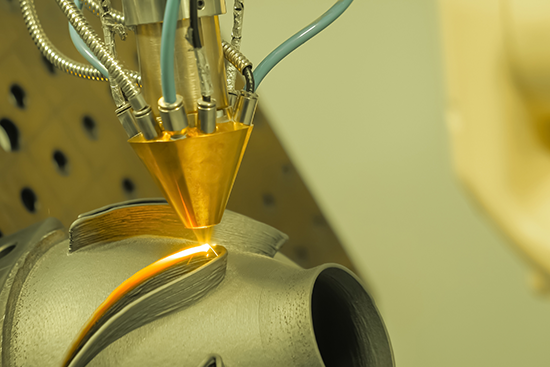

Directed energy deposition (DED) is a method used for 3D printing and repairing metal parts. Although it provides a very flexible and efficient means for the manufacture and repair of high-value components, DED often results in surface irregularities called humping, which can lead to cracks and reduce the strength of the printed parts. To better understand this problem and find solutions, researchers from Rolls Royce plc, Queen’s University and University College London, used a combination of two imaging techniques: inline coherent imaging (ICI), and in situ X-ray imaging at Diamond1.

Directed energy deposition (DED) is a method used for 3D printing and repairing metal parts. Although it provides a very flexible and efficient means for the manufacture and repair of high-value components, DED often results in surface irregularities called humping, which can lead to cracks and reduce the strength of the printed parts. To better understand this problem and find solutions, researchers from Rolls Royce plc, Queen’s University and University College London, used a combination of two imaging techniques: inline coherent imaging (ICI), and in situ X-ray imaging at Diamond1.

By aligning the ICI system with the DED system and the I12 beamline, the researchers were able to accurately monitor the surface of the printed parts and detect cracks as small as 7 micrometers. This is important because cracks can significantly weaken the parts and reduce their lifespan. The researchers also found that the humping on the surface of the parts increased the likelihood of crack formation.

Thin-walled structures, which are commonly used in industries like aerospace and automotive, are particularly prone to humping and cracking. The use of X-ray imaging and ICI will provide valuable insight into the formation and growth of cracks during the DED process. This knowledge can be used to improve the quality and reliability of 3D-printed metal parts, especially in industries where thin-walled structures are used.

1. ICI is a type of optical imaging that can monitor the surface of the printed parts in real-time and detect cracks as they form. It provides detailed information about the roughness and waviness of the surface. On the other hand, synchrotron X-ray imaging allows the researchers to see what's happening beneath the surface, specifically the growth and healing of cracks.

Diamond Light Source is the UK's national synchrotron science facility, located at the Harwell Science and Innovation Campus in Oxfordshire.

Copyright © 2022 Diamond Light Source

Diamond Light Source Ltd

Diamond House

Harwell Science & Innovation Campus

Didcot

Oxfordshire

OX11 0DE

Diamond Light Source® and the Diamond logo are registered trademarks of Diamond Light Source Ltd

Registered in England and Wales at Diamond House, Harwell Science and Innovation Campus, Didcot, Oxfordshire, OX11 0DE, United Kingdom. Company number: 4375679. VAT number: 287 461 957. Economic Operators Registration and Identification (EORI) number: GB287461957003.