Better understanding of the distribution of elastic and plastic strains in deformed polycrystalline, multiphase materials is important for structural engineering. The deformation response depends upon the interaction of grains of different orientations, and the anisotropy associated with each phase. Strain partitioning and tensile-compressive hardening asymmetry arises due to mismatches in modulus and ductility between grains and phases in alloys such as Ti-6Al-4V, or Ni-base superalloys used in aeroengine manufacturing. For example, Ti-6Al-4V displays both strong anisotropy of mechanical properties within one phase, and significant differences between phases. On the high-energy white-beam synchrotron beamline I12 (JEEP) at Diamond Light Source, we used the energy-dispersive X-ray diffraction setup to study simple four-point beam bending samples of Ti-6Al-4V. Diffraction patterns from the bent polycrystalline Ti6Al4V samples were collected using the new 23-cell “horseshoe” detector and interpreted using Pawley refinement to extract unit cell parameters, thus allowing elastic strain to be determined. The tensile-compressive yielding asymmetry was quantified for the grains oriented with the basal plane perpendicular to the loading direction. Initial evaluation of the performance of the new instrument is reported.

The new JEEP beamline possesses excellent versatility: a broad spectrum of high energy X-ray photons (50 to 150 keV), and the capacity to perform imaging and diffraction experiments in the monochromatic and white beam modes. The two large hutches (internal and external) provide flexible arrangements for performing complex experiments involving in situ processing operations.

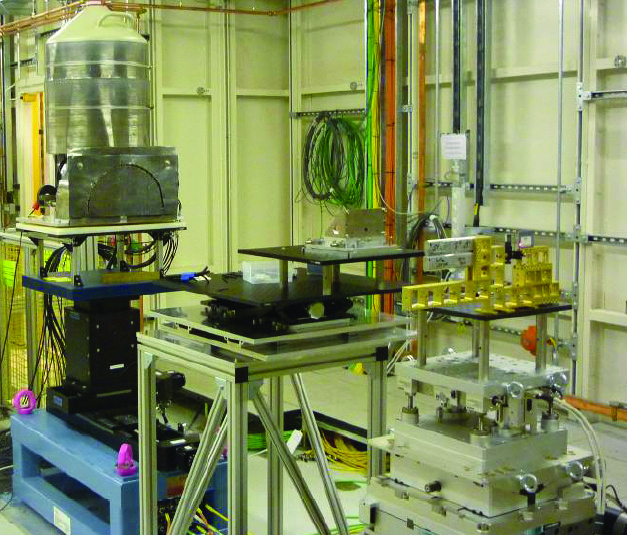

Figure 1: (a) Energy dispersive setup in the internal I12 JEEP hutch with the “horseshoe” detector. (b) Example diffraction pattern data from all 23 detector cells.

One further direction of technique development pursued by the Oxford group concerns the use of small beams to interrogate the orientation and strain within individual grains using collimated or focused high energy polychromatic X-ray beams (micro-beam Laue). Preliminary studies have been carried out on ESRF beamlines BM32 and ID15A. Of particular interest has Laue diffraction methods that have the potential to provide fast and reliable methods for determining 3D microstructure and strain within alloy samples of practical applied interest e.g. to the aerospace industry.

Most engineering metallic alloys are used in polycrystalline form. Internal stresses at the microscopic scale (inter-granular and intra-granular) play a crucial role in determining the deformation response of these alloys, both under monotonic and cyclic loading, as well as their resistance to fatigue crack initiation and propagation. Understanding the nature and evolution of micro-stresses in polycrystals requires the combination of deformation modelling with experimental data obtained non-destructively and at the appropriate scale. Diffraction of penetrating radiation, such as the high flux, high brightness synchrotron X-rays, provides a uniquely powerful tool for the purpose of experimental characterisation. The strains associated with each phase can be quantified separately, allowing strain partitioning between phases to be assessed.

The purpose of the recent I12 JEEP experiment was to study a pre-deformed sample of polycrystalline alloy Ti-6Al-4V: collect multi-peak polycrystal diffraction patterns, deduce the state of (residual) strain within it, and to interpret the results in terms of the deformation response of individual phases and grain groups. This mode of polycrystal deformation analysis may be most appropriately described as “mesoscopic”, since the interpretation is carried out at the level of sub-macroscopic selective averaging across the grain ensemble. An additional purpose of the study was to provide an initial evaluation of the new energy-dispersive X-ray diffraction (EDXD) setup at Diamond Light Source.

The experimental setup is illustrated in Fig.1a. The multiple peak diffraction patterns obtained simultaneously from the 23 cells of the horseshoe detector are shown in Fig.1b.

In hexagonal close-packed (HCP) crystals of α-Ti, the elastic and plastic properties exhibit a large degree of anisotropy, with a 30% difference between single crystal Young’s moduli perpendicular and parallel to the basal plane. Easy slip in HCP crystals is associated with the close-packed directions in the basal plane, resulting in the easiest yield and highest ductility when loaded perpendicular to the c-axis, compared to loading along the c-axis. This strong directional dependence of the elastic and plastic properties of single crystals of α-Ti is also reflected in the macroscopic behaviour of polycrystals.

Figure 2: (a) Overall orientation map of the for the specimen obtained by high energy transmission microbeam Laue. The crystallographic triangle indicates the colour scheme. (b) the orientation map for the region of interest, and (c) SEM micrograph of the sample surface (d) Peak identification on the transmission Laue diffraction pattern (indices omitted for clarity).

The results obtained provided the quantification of strain partitioning between phases and grain orientations within polycrystalline two-phase titanium alloy Ti-6Al-4V. In particular, the tensile/compressive hardening asymmetry of a particular group of grains (“c-group”) was highlighted. The results were obtained by careful and precise analysis of energy-dispersive synchrotron X-ray diffraction data from the JEEP instrument at Diamond Light Source. Strain measurement accuracy better than 50×10-6 was achieved.

The polycrystalline diffraction setup described above and used in the first set of experiments on JEEP provides insight into the meso-scale average behaviour. However, often the knowledge of strains within individual grains is also important, since structural failure is often controlled by the “weakest link”. The typical size of the probe required for this purpose is small (a few microns).

In order to develop ideas for intra-granular deformation analysis on the JEEP beamline at Diamond, we undertook a preliminary exploratory study on the ESRF beamline ID15A that shares some characteristics with I12 at Diamond. The technique we used for the purpose of intra-granular analysis is called micro-beam Laue diffraction. It involves directing a collimated (or, preferably, micro-focused) white beam at a region within a single grain, collecting and indexing a two-dimensional diffraction pattern, and deducing grain orientation and deviatoric strain from it.

The technique has originally been developed for use with moderate photon energies (5-25 keV) in the reflection geometry. However, it is the ability to probe non-destructively the microstructure and strain within the bulk of materials that remains one of the major challenges in the field. For that reason we attempted to use photons of higher energy (50-150 keV) in transmission mode.

Fig. 2d shows the indexed transmission Laue diffraction pattern obtained from a sample of commercially pure nickel alloy. The microstructure of the sample is illustrated in Fig. 2c, and the orientation maps of the entire sample and the region of interest are shown in Fig.1a and Fig. 1b, respectively.

This initial study demonstrated the viability and efficiency of this technique. In the next experiment that we will carry out on I12 JEEP at Diamond we intend to develop this approach further towards the goal of 3D characterisation.

References

[1] S. Balasubramanian and S. Anand, Plasticity of initially textured hexagonal polycrystals at high homologous temperatures: application to titanium, Acta Materialia: 50, 133–148 (2002).

Principal Publications and Authors

A. M. Korsunsky, X. Song, F. Hofmann, B. Abbey, M. Xie, T. Connolley, C. Reinhard, R. C. Atwood, L.Connor, M. Drakopoulos, Polycrystal deformation analysis by high energy synchrotron X-ray diffraction on the I12 JEEP beamline at Diamond Light Source, Materials Letters, Volume 64, Issue 15, 1724-1727 (2010).

F. Hofmann, X. Song, T.-S. Jun, B. Abbey, M. Peel, J. Daniels, V. Honkimäki and A.M. Korsunsky, High energy transmission micro-beam Laue synchrotron X-ray diffraction, Materials Letters, Volume 64, Issue 11, 1302-1305 (2010).

Funding Acknowledgement:

Engineering and Physical Sciences Research Council in the UK project EP/H003215/1.

Research carried out at Diamond on I12 and at the ESRF on ID15A, BM32.

Diamond Light Source is the UK's national synchrotron science facility, located at the Harwell Science and Innovation Campus in Oxfordshire.

Copyright © 2022 Diamond Light Source

Diamond Light Source Ltd

Diamond House

Harwell Science & Innovation Campus

Didcot

Oxfordshire

OX11 0DE

Diamond Light Source® and the Diamond logo are registered trademarks of Diamond Light Source Ltd

Registered in England and Wales at Diamond House, Harwell Science and Innovation Campus, Didcot, Oxfordshire, OX11 0DE, United Kingdom. Company number: 4375679. VAT number: 287 461 957. Economic Operators Registration and Identification (EORI) number: GB287461957003.