| ||

Where do metals diffuse inside a nanoparticle? |

Beamline I07 Scientific Highlight

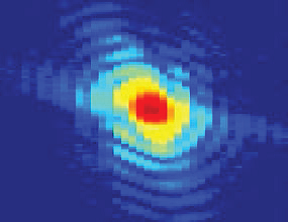

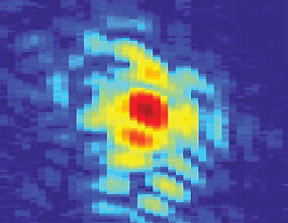

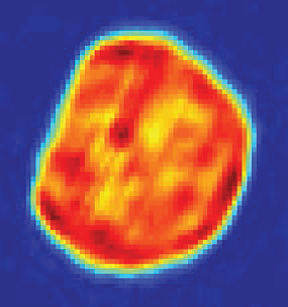

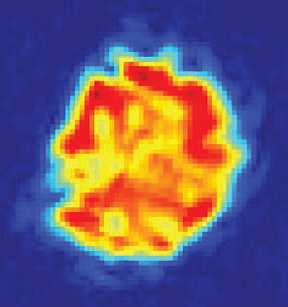

Figure 1: (top left) and (top right) central section of the BCDI diffraction patterns, measured at I07, of the 111 Bragg peak of a gold nanocrystal before and after deposition of copper on top of it at 600 °C; (bottom left) and (bottom right) cross sections through the inverted images obtained from the full 3D diffraction patterns. Scale bar is 100 nm.

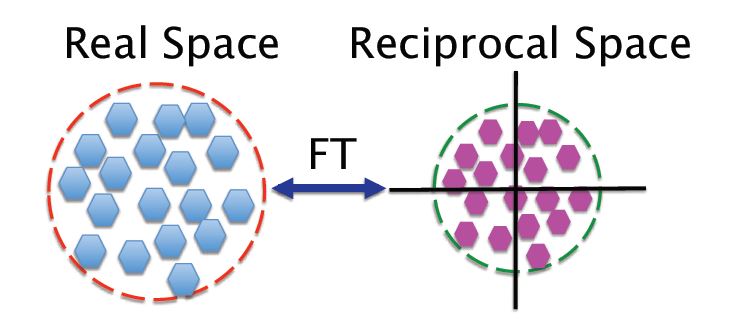

Figure 2: Schematic diffraction pattern (right) of a bounded array of small sub-objects within an enclosed object region (left). The envelope width of the diffraction pattern is the reciprocal of the size of the sub-objects while the speckle size is the reciprocal of the whole ensemble. An immediate consequence of this reciprocity is that the number of speckles is numerically equal to the number of sub-objects in the ensemble. FT denotes Fourier Transform.

The Bragg Coherent Diffraction Imaging (BCDI) method was developed over the late 1990s and 2000s by the group of Ian Robinson. BCDI converts the 3D diffraction pattern from the rocking curves into real-space 3D images of the crystal. Only when the beam is coherent, are the fringes surrounding the Bragg peak fully resolved; if many crystals were averaged together (as in powder diffraction experiments) or many crystals were superimposed, these fringes would all be washed out and the BCDI experiment would fail. The second requirement for BCDI is that the recording of the fringes must be oversampled on the detector. This point relates to the famous Shannon sampling theorem that says that the complete information about a bandlimited signal is contained in two measurements per period of the signal at its cut-off frequency. Applied here, the Shannon condition means the detector needs to be positioned far enough away from the sample that the recording has at least two pixels per fringe. Once this condition is satisfied, there are sufficient measurement points for the inversion of the diffraction to an image to be a mathematically overdetermined problem, hence can be solved. A variety of BCDI algorithms have been invented which effectively solve this phase problem1.

Source publication:

Xiong, G., Clark, J. N., Nicklin, C., Rawle, J. & Robinson, I. K. Atomic Diffusion within Individual Gold Nanocrystal. Scientific Reports 4, doi:10.1038/srep06765 (2014).

References:

1. Fienup, J. R. Phase retrieval algorithms - a comparison. Applied Optics 21, 2758-2769 (1982).

Funding acknowledgements:

EP/I022562/1 “Phase modulation technology for X-ray imaging” and ERC Advanced Grant 227711 “Exploration of strains in synthetic nanocrystals”.

Corresponding author:

Professor Ian Robinson, University College London; Research Complex at Harwell; Tongji University, i.robinson@ucl.ac.uk

A brighter light for science

A brighter light for science