Find out more about our ambitious upgrade project, delivering more brightness, more coherence, and greater speed of analysis to UK science. More about Diamond-II

![]()

Find out more about Diamond's response to virus research.

![]()

In 2018 a significant milestone in the history of the Charles Hatchett Award was reached. An impact report has been published to demonstrate the technical impacts and benefits the Award has delivered over the past 40 years.

Download 40 years of the Charles Hatchett Award Impact Report here to learn more.

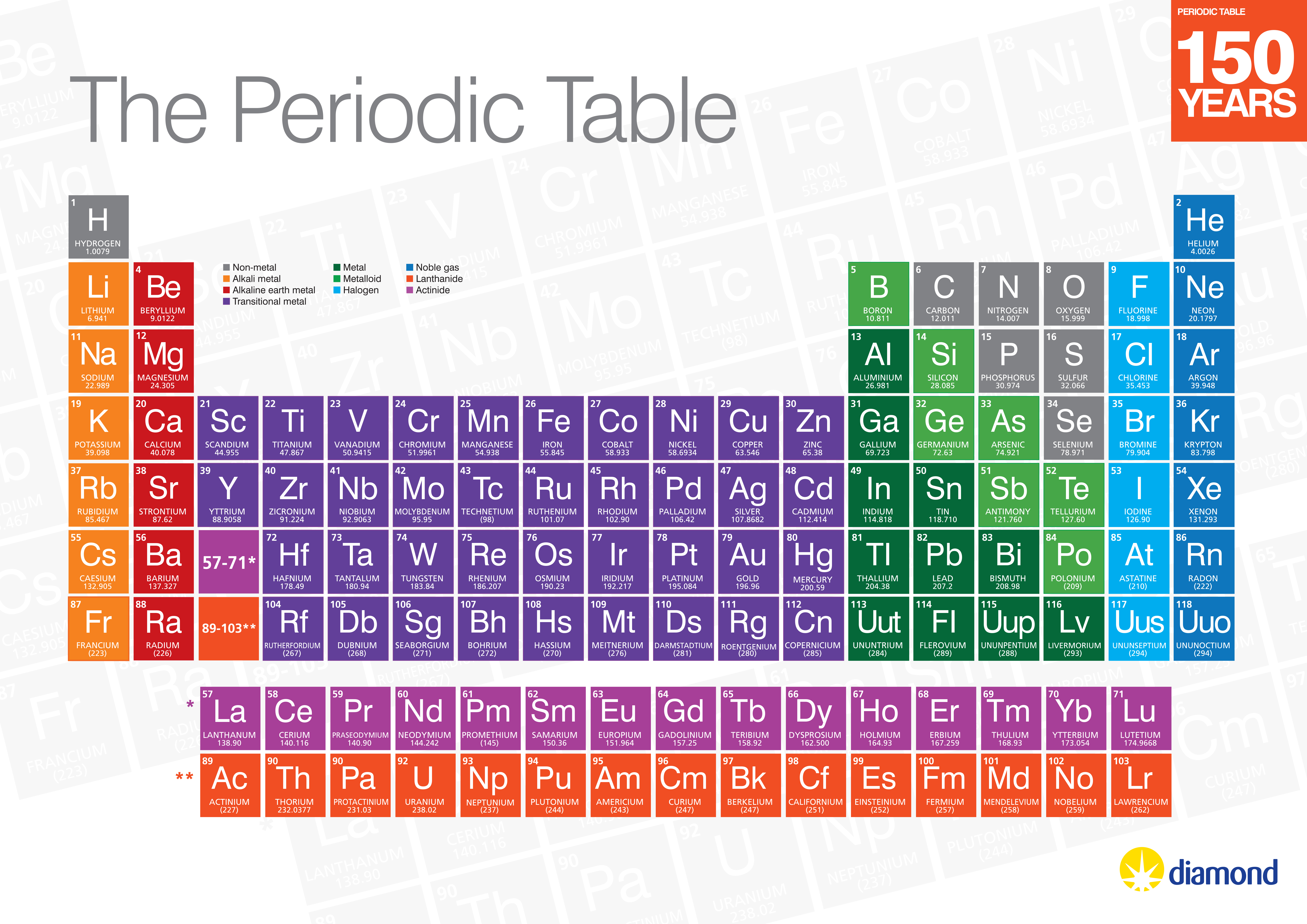

Charles Hatchett FRS (1765 – 1847) was a wealthy London coachbuilder, an amateur scientist and the discoverer of niobium. This element, atomic number 41, is now known as niobium (Nb) although the name columbium persists in some parts of the world.

Learn more about the elements we use here at Diamond by exploring our International Year of the Periodic Table celebrations!

Award winners from left to right: Kent Griffith, Lauren Marbella, Clare Grey, and Giannantonio Cibin of Diamond Light Source

An international research team from the University of Cambridge, Diamond Light Source and the Advanced Photon Source have been awarded the 2019 Charles Hatchett Award. Given for originality and technical excellence and the bestpaper on the science and technology of niobium-based materials, the winners were announced as Kent J. Griffith (UK), Kamila M. Wiaderek (USA), Giannantonio Cibin (UK), Lauren E. Marbella (UK) and Clare P. Grey (UK), for their paper published in Nature: ‘Niobium Tungsten Oxides for High-rate Lithium-ion Energy Storage’ Nature, 559 (2018), 556-563

The University of Cambridge team studied a new material that could improve the charging speed and storage capacity of rechargeable batteries for use in electric vehicles and mobile devices at Diamond, the UK’s synchrotron, and at the Advanced Photon Source in the US. Niobium tungsten oxide is able to store an unexpectedly large quantity of energy and the team used the Core X-ray Absorption Spectroscopy (XAS) beamline (B18) to investigate the chemical changes that occur in these materials.

Principal Beamline Scientist, Giannantonio Cibin at Diamond explains;

We need to develop new electrode materials for batteries which will improve both charge/discharge rates and increase storage capacities. This is really important for growing markets such as electric vehicles, portable appliances and large-scale energy storage. This research highlights why two complex niobium-tungsten oxides show higher energy and power densities than those in battery materials currently available.

The selection process of the Charles Hatchett Award is concerned with technical excellence and originality, but also takes account of the social, economic and environmental advantages of any proposed application of niobium. The International Panel for the Charles Hatchett Award commented, “This paper deals with a very important research topic with potential commercial applications involving the use of niobium: how to significantly increase the capacity and reduce the charging time of Li-ion batteries. The research used a very wide range of experimental methods, producing extensive experimental data. The potential applications of the technology could have clear sustainability-related impacts by promoting the use of non-carbon energy storage and usage.”

CEO of Diamond, Professor Andrew Harrison added;

As a leading-edge facility for scientific research supporting a wide range of users from both academia and industry, we are extremely proud of this potentially world changing science that has been undertaken on our B18 Beamline into new fast charging and high-power battery materials. We hope their award-winning research will unlock new benefits to our society and economy and further studies are eagerly expected.

The annual Award, now in its 41st year, is sponsored by CBMM and administered by Beta Technology. The award winners were presented with their medals at the Institute of Materials, Minerals and Mining (IOM3) 2019 Premier Awards Dinner, held last week in London.

Diamond Light Source is the UK's national synchrotron science facility, located at the Harwell Science and Innovation Campus in Oxfordshire.

Copyright © 2022 Diamond Light Source

Diamond Light Source Ltd

Diamond House

Harwell Science & Innovation Campus

Didcot

Oxfordshire

OX11 0DE

Diamond Light Source® and the Diamond logo are registered trademarks of Diamond Light Source Ltd

Registered in England and Wales at Diamond House, Harwell Science and Innovation Campus, Didcot, Oxfordshire, OX11 0DE, United Kingdom. Company number: 4375679. VAT number: 287 461 957. Economic Operators Registration and Identification (EORI) number: GB287461957003.