Find out more about our ambitious upgrade project, delivering more brightness, more coherence, and greater speed of analysis to UK science. More about Diamond-II

![]()

Find out more about Diamond's response to virus research.

![]()

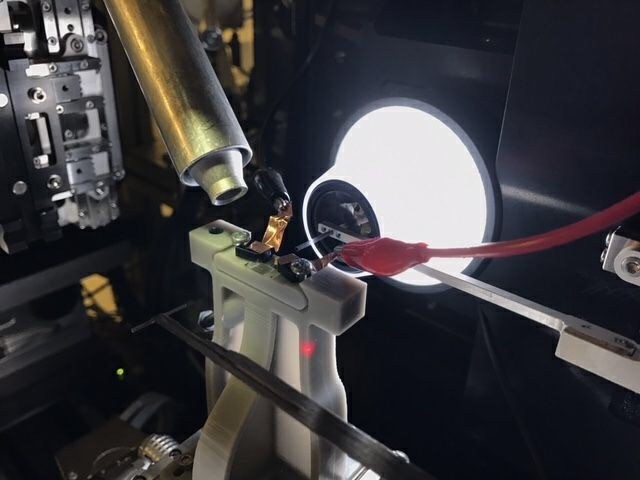

The development of an acoustic on-chip goniometer, reported in Lab on a Chip, offers real advantages for synchrotron-based macromolecular crystallography (MX). It reduces the need for manual sample manipulation or complex robotics, and allows high-throughput sorting, chemical treatment and analysis. With a uniquely small footprint and low cost, the acoustic on-chip goniometer is an elegant solution designed for room temperature use, maximising the data that can be captured from individual crystals and reducing the amount of sample required.

Christian Burton, Diamond’s joint PhD student with Aston University, and his Diamond Supervisor Peter Docker, in conjunction with Notthingham Trent University, have been investigating ways to improve sample throughput at facilities such as Diamond. It is important for users to collect as much data as possible during their beamtime sessions, and a diverse set of techniques has been developed to increase throughput in MX crystal handling. MX relies on the coordination of many complex, high-precision processes, both manual and mechanical, but advances in detector technology and X-ray optics mean that synchrotron-based MX can now benefit from new techniques.

To successfully determine the structure of a macromolecule using X-ray crystallography, a complete set of reflections (specifically-oriented scattered beams) has to be captured by a 2D detector. This is traditionally accomplished with a mechanical goniometer. In order to remove the need for manual adjustments, without relying on complex robotics, a team of researchers has developed an approach using acoustic handling, which has been shown to be safe for several types of protein crystal.

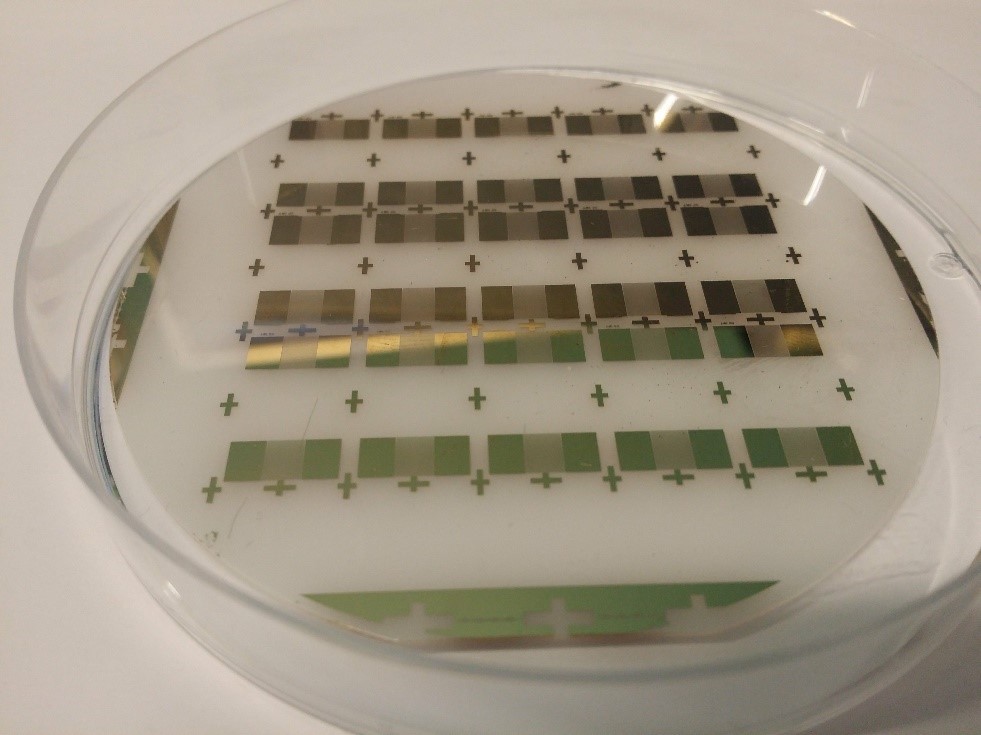

The acoustic on-chip goniometer is designed to work with crystals suspended in their native liquid, which offers them some protection against the X-ray beam and ensures a longer lifespan. It uses a surface acoustic wave transducer to create a vortex inside a drop of the sample placed on the chip. The vortex suspends a spinning protein crystal in the X-ray beam, allowing the collection of a complete set of reflections at random orientations. This technique is similar to the serial methods pioneered at XFEL (X-ray free-electron laser) sources, in which single detector collects images from thousands of randomly oriented crystals.

In this Standing Surface Acoustic Wave (SSAW) actuation system, the velocity of the samples within the drop is controlled via the amplitude of the signal waveform. For the experiments on Diamond’s Micofocus MX beamline (I24), a 2 µl drop of the sample (containing multiple crystals) was manually placed onto the chip immediately before data collection. Observations support the model of a central crystal spinning on the beam, with other crystals orbiting it. The results confirm that the on-chip goniometer is capable of producing useful structures from acoustically perturbed samples.

These experiments have demonstrated that on-chip crystal rotation is an efficient method for in situ room temperature collection of X-ray data for protein crystals. By achieving a high resolution structure, the device makes a significant stride in automated sample handling. The next stage is to incorporate microfluidics into the experimental design, with the ultimate aim of developing a full lab-on-a-chip system, as well as supporting bespoke software for such goniometer-based experiments, rather than using existing serial crystallography data analysis methods. As well as providing automated sample delivery without the need for large, expensive and complex robotics, a lab-on-a-chip system would be invaluable for use in sealed environments (e.g. for preventing evaporation), and for hazardous or delicate samples.

To find out more about the project, please contact Dr Pete Docker: peter.docker@diamond.ac.uk.

Burton CG et al. An acoustic on-chip goniometer for room temperature macromolecular crystallography. Lab on a Chip (2017). DOI: 10.1039/C7LC00812K.

Diamond Light Source is the UK's national synchrotron science facility, located at the Harwell Science and Innovation Campus in Oxfordshire.

Copyright © 2022 Diamond Light Source

Diamond Light Source Ltd

Diamond House

Harwell Science & Innovation Campus

Didcot

Oxfordshire

OX11 0DE

Diamond Light Source® and the Diamond logo are registered trademarks of Diamond Light Source Ltd

Registered in England and Wales at Diamond House, Harwell Science and Innovation Campus, Didcot, Oxfordshire, OX11 0DE, United Kingdom. Company number: 4375679. VAT number: 287 461 957. Economic Operators Registration and Identification (EORI) number: GB287461957003.