Find out more about our ambitious upgrade project, delivering more brightness, more coherence, and greater speed of analysis to UK science. More about Diamond-II

![]()

Find out more about Diamond's response to virus research.

![]()

The Year of Engineering is all about celebrating the world and wonder of the industry, and exploring the wide range of ideas and innovations that Engineering involves. Today, we're having a look at Diamond's Beamline I23 - a specially designed instrument for protein crystallography that uses long wavelengths.

There are unique engineering scientific challenges involved in designing a system that will allow researchers to use long wavelengths of Synchrotron radiation effectively. The special cryogenically-cooled sample gripper on I23, is one of the solutions that makes this beamline successful. Learn more about this engineering innovation.

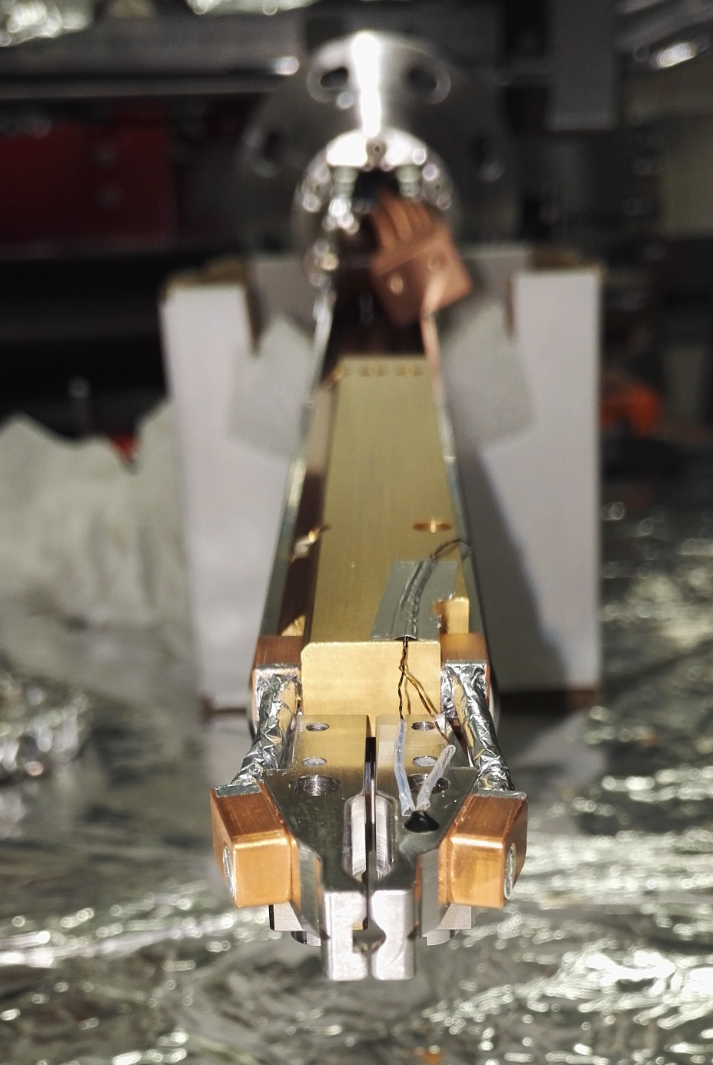

Beamline I23 at Diamond is a unique instrument dedicated for protein crystallography using long wavelengths. While it opens new scientific opportunities, operation at long wavelengths comes with various challenges, mainly due to increased absorption effects and the need to access larger diffraction angles. The experiment endstation is a large vacuum vessel with a cryogenically cooled goniometer to position and orient protein crystals for data collection, a large semi-cylindrical Pilatus 12M detector and a cryogenically cooled sample storage and transfer mechanism using an actively cooled gripper in a high vacuum environment. Protein crystals are very fragile and need to be cryogenically cooled for storage and transport in vacuum and at temperatures below 140 K.

Once the protein crystals are harvested from the solvent using sample holders, they are frozen in liquid nitrogen and loaded on to a copper sample block which can accommodate four sample holders. The block containing four samples is transferred into the endstation vacuum vessel and onto a cryogenically cooled storage system or sample hotel using a Leica® transfer shuttle. The sample hotel then rotates 180° to align a sample block with the gripper. The gripper is then aligned with the chosen sample by moving it in the horizontal and vertical directions. The sample is then removed from the sample hotel and transferred by the gripper to the goniometer (you can see this in action in the leading video). The sample or crystal is then centered on the goniometer and exposed to the X ray beam resulting in a diffraction pattern which is recorded by the detector.

Diamond Engineers have developed a new actively cooled gripper to reliably transfer crystals in a high vacuum environment. The gripper assembly is designed to operate in a very small space envelope due to tight boundary constraints defined by other existing subassemblies. Its gripping fingers are cryogenically cooled to 90 K to ensure that the temperature of the crystals does not exceed 140 K during the transfer process. The gripper assembly is required to have a long travel stroke of 300 mm in the X-axis to be able to pick a sample from the sample hotel and deliver it to the goniometer. The “pick and place” repeatability of the gripper needs to be less than 25 µm in all 3 linear axes due to very tight tolerances between the sample holder, the block and the goniometer receptacle. To ensure that the gripper meets the required repeatability and reliability, it was rigorously tested using high precision capacitive sensors (watch one of these tests in the video below) in different environments such as ambient temperature and pressure, high vacuum and at cryogenic temperatures.

The sample grip and release is achieved using a small 16 mm diameter DC motor connected to a titanium flexure. The bespoke gripping fingers which are attached to the flexure are designed to match the contour of the unique I23 sample holders for optimised grip and to maximise heat transfer for conductive cooling.

We at Diamond constantly strive to push the boundaries in different areas of engineering such as precision mechanisms, cryogenics, vacuum technology, metrology, electronics and control systems. All these make discoveries using X-rays possible, exciting and rewarding.

Diamond Light Source is the UK's national synchrotron science facility, located at the Harwell Science and Innovation Campus in Oxfordshire.

Copyright © 2022 Diamond Light Source

Diamond Light Source Ltd

Diamond House

Harwell Science & Innovation Campus

Didcot

Oxfordshire

OX11 0DE

Diamond Light Source® and the Diamond logo are registered trademarks of Diamond Light Source Ltd

Registered in England and Wales at Diamond House, Harwell Science and Innovation Campus, Didcot, Oxfordshire, OX11 0DE, United Kingdom. Company number: 4375679. VAT number: 287 461 957. Economic Operators Registration and Identification (EORI) number: GB287461957003.