Find out more about our ambitious upgrade project, delivering more brightness, more coherence, and greater speed of analysis to UK science. More about Diamond-II

![]()

Find out more about Diamond's response to virus research.

![]()

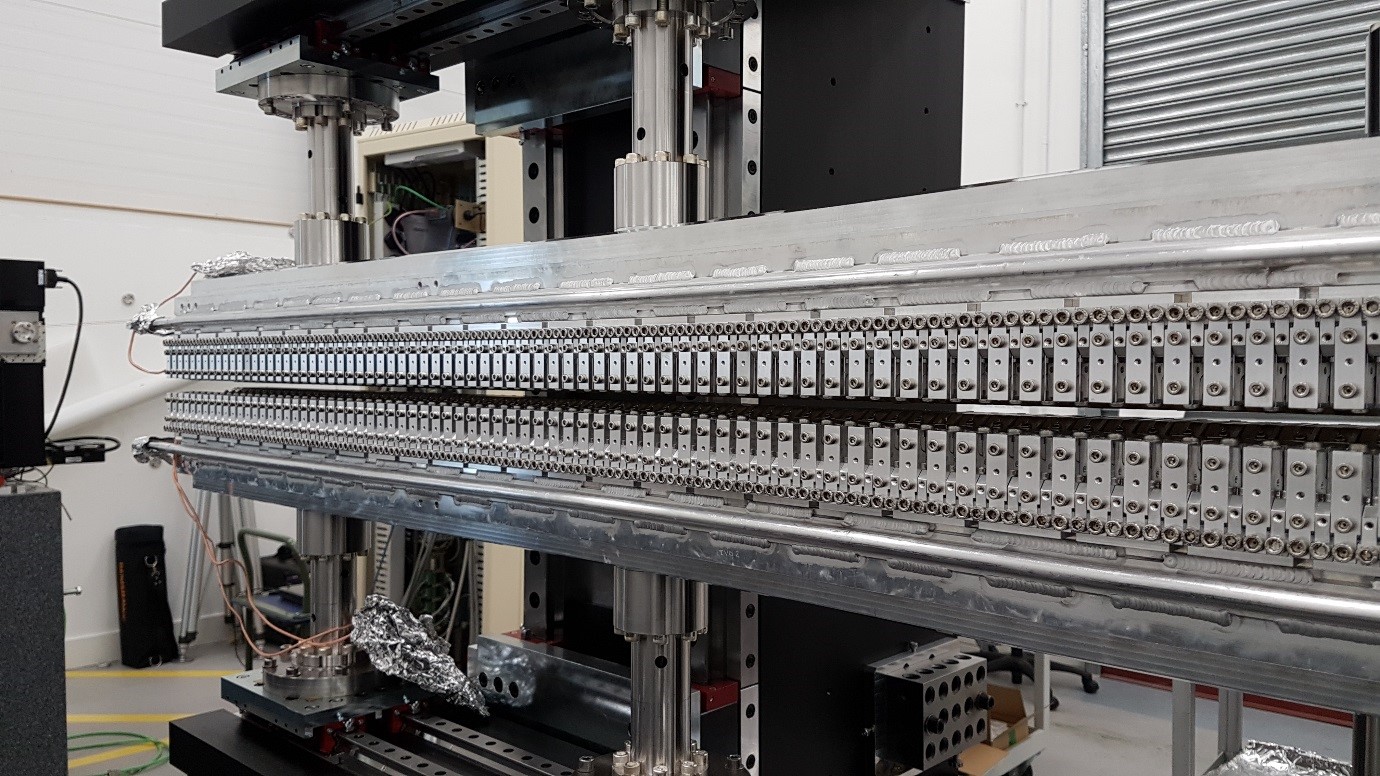

Tens or even hundreds of magnets are clamped very precisely along an aluminium alloy beam, two of these magnet filled beams are then placed opposite each other and as the electron beam travels along the gap between them high intensity X-rays are produced. (see animation below)

Sounds simple, but dealing with such powerful magnets has its problems. These magnets produce huge forces, even a magnet on its own must always be clamped down and never handled by hand. The largest magnet currently used is about the size of a hardback novel and two of these 22mm apart will lift 200kg.

The quality of the X-rays produced also depends on how uniform the magnets are. The magnets have some slight variations and so from each batch manufactured only the best ones are chosen, in addition each magnet has to be adjusted within a few microns to create the perfect magnetic field.

Holding the magnets apart requires some very strong and stiff structures to ensure that the magnets keep their position with a few microns even when subjected to up to 5 Tonnes of attractive force. The gap between the magnets also needs to be varied. By changing the gap the energy of the X-rays changes so this enables the beamline team to tune the peak X-ray energy to match the needs of the experiment. To adjust the gap large servo motors drive a set of heavy duty precision ball screws that pulls the magnets apart.

Many of these magnet systems operate in air with a thin walled vacuum vessel located between the magnets. The electron beam has to operate in vacuum and so to get even more X-rays produced we would like to get the magnets even closer together. So how about putting the magnets inside the vacuum vessel?

Diamond Light Source is the UK's national synchrotron science facility, located at the Harwell Science and Innovation Campus in Oxfordshire.

Copyright © 2022 Diamond Light Source

Diamond Light Source Ltd

Diamond House

Harwell Science & Innovation Campus

Didcot

Oxfordshire

OX11 0DE

Diamond Light Source® and the Diamond logo are registered trademarks of Diamond Light Source Ltd

Registered in England and Wales at Diamond House, Harwell Science and Innovation Campus, Didcot, Oxfordshire, OX11 0DE, United Kingdom. Company number: 4375679. VAT number: 287 461 957. Economic Operators Registration and Identification (EORI) number: GB287461957003.