Keep up to date with the latest research and developments from Diamond. Sign up for news on our scientific output, facility updates and plans for the future.

Related publication: Chmiel F. P., Waterfield Price N., Johnson R. D., Lamirand A. D., Schad J., Van Der Laan G., Harris D. T., Irwin J., Rzchowski M. S., Eom C. B. & Radaelli P. G. Observation of magnetic vortex pairs at room temperature in a planar α-Fe2O3/Co heterostructure. Nat. Mater. 17, 581–585 (2018). DOI: 10.1038/s41563-018-0101-x

Publication keywords: Absorption; Spectra; Vortices

In spite of its extraordinary success in fuelling the IT revolution, silicon (CMOS) technology is intrinsically energy-inefficient. The heat flux generated by microprocessors is comparable to that on the Sun’s surface, and their clock speeds stopped growing a decade ago to prevent complete meltdown. At the core of the problem is the fact that CMOS relies on the movement of electrical charge, which is associated with Joule heating. Although its commercial success seems unstoppable, power-hungry CMOS is ultimately doomed, and IT companies are actively scouting for new energy-efficient technologies to replace it. A nominal target of 1 attojoule/operation ought to be possible – after all, the human brain uses up approximately 1.5 attojoule/operation, and the ultimate physical limit (dictated by the so-called Landauer principle) is ~0.003 attojoule/operation at room temperature. However, we would have to improve by a factor of 1,000,000 to reach this target.

Several novel technologies are being investigated to address this crucial issue. One of the front runners among these ‘beyond-CMOS’ technologies is spintronics, which relies on spins rather than charges to process information. However, much of the energy-efficiency of spintronics is lost if spin flipping – the elementary spintronic operation – must itself be performed by electrical currents. For this reason, voltage control of magnetic components is widely considered to be the key to large-scale commercialisation of spintronics. The field of oxide electronics emerges precisely from the consideration that oxides can display a multitude of intriguing multi-functional properties in their insulating states. Moreover, oxides are already integrated with CMOS, are generally stable, and are compatible with other spintronic components. Insulating oxides of magnetic transition metals such as iron, cobalt, and manganese, have many of the required properties to achieve voltage control of spins, since their charge, orbital, and magnetic states are intertwined. This can be further enhanced by exploiting the power of topology. It is well known that ordinary magnetic ‘bits’ are thermally unstable when very small in size, but this can be overcome, quite literally, by tying the spins into ‘magnetic knots’. Very recently, topological structures such as skyrmions, vortices, and 'merons' (see below) have shown enormous potential to enhance the performances of both spintronics and oxide materials, since they can be stable at room temperature and above even when very small, and can be manipulated at very low energy cost.

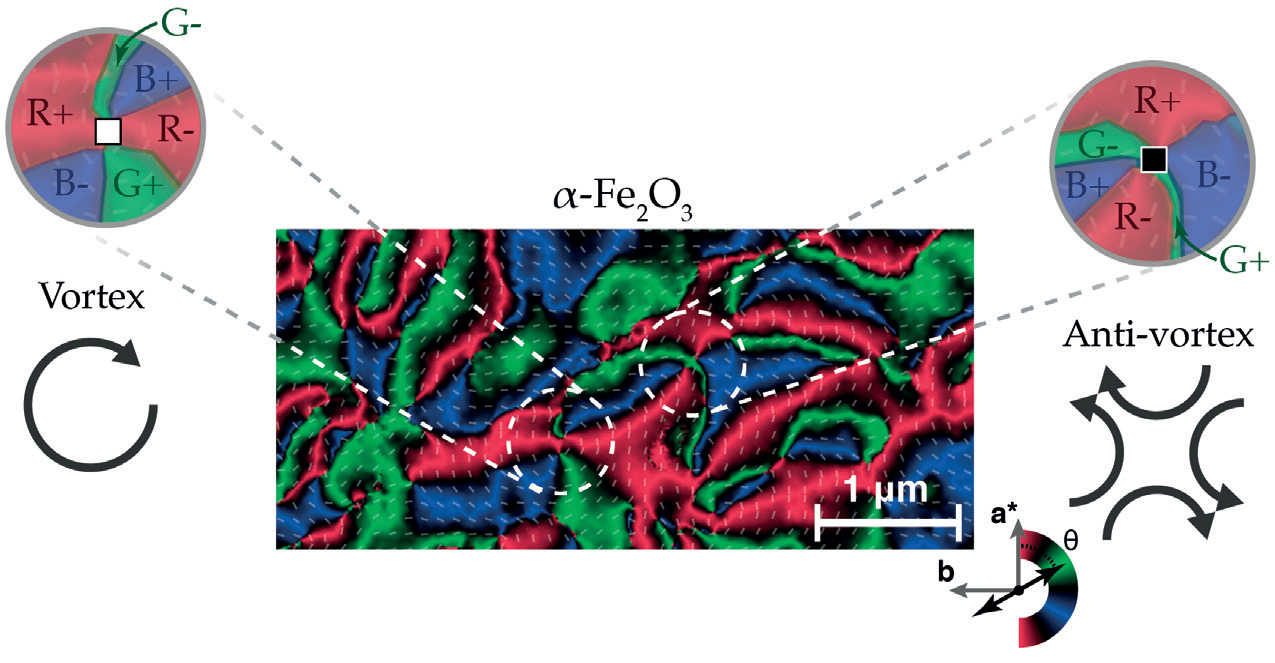

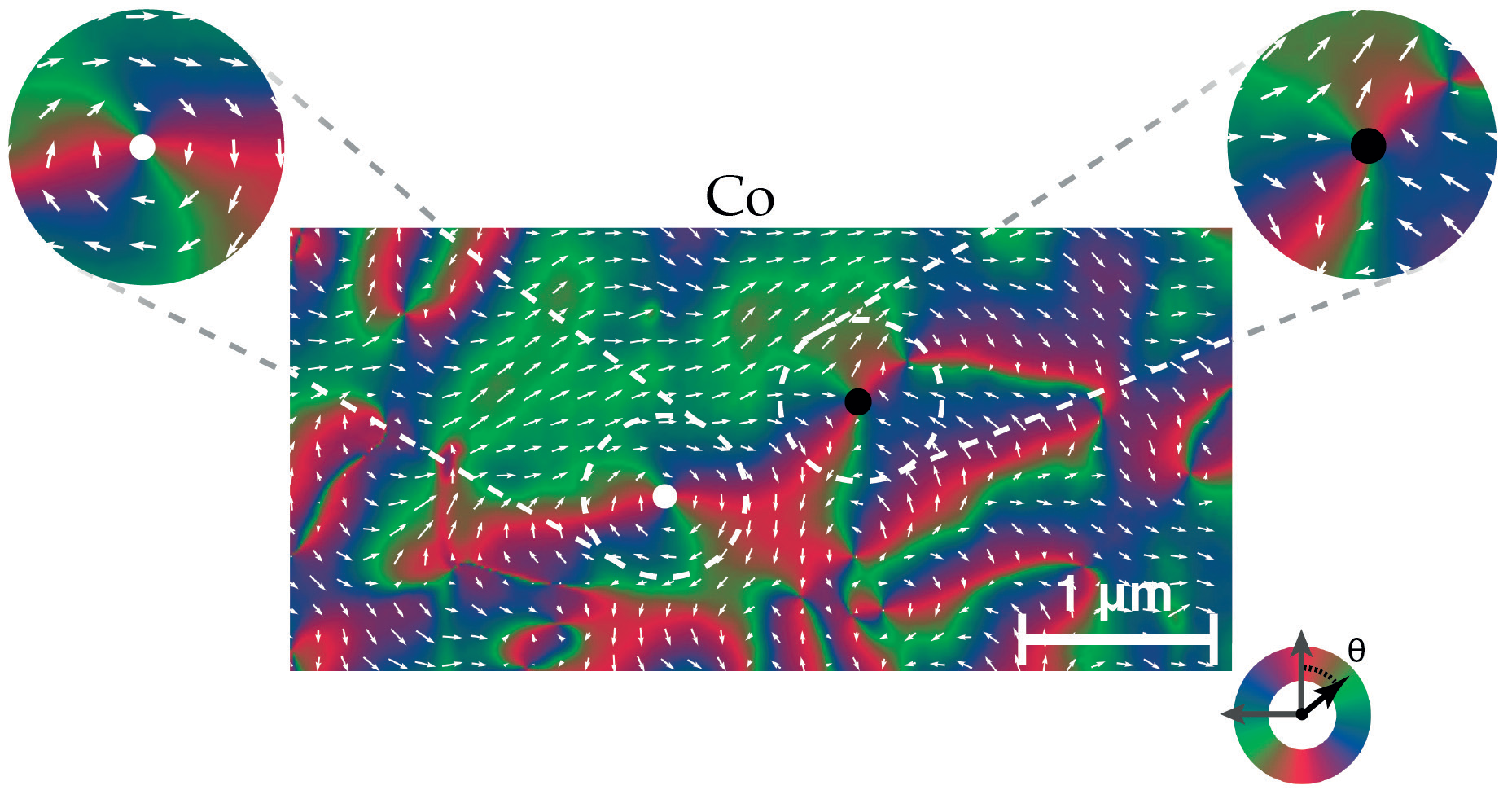

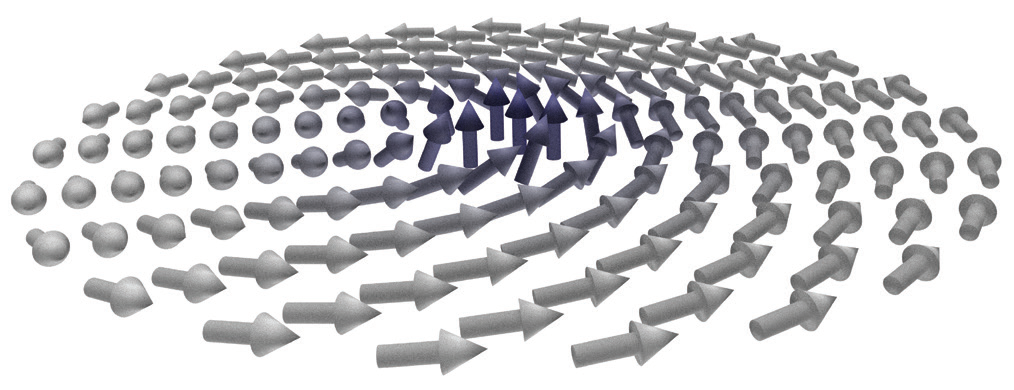

The experiments were performed using the I06 beamline at Diamond, reconstructing a single spin map by merging polarisation dependent X-PEEM images recorded across a range of different sample orientations. This technique, known as vector mapping, takes advantage of the anisotropic nature of XAS in ferromagnets or antiferromagnets. This method was first applied to image the antiferromagnetic spin map of the Fe2O3 layer (Fig. 1) revealing a network of whirling magnetic vortices hundreds of nanometres in size, as well as more exotic anti-vortices. Based on Kibble’s theory, vortices and anti-vortices can annihilate, and they were seen occasionally to do so in the experiment (perhaps under the influence of the X-ray beam), although most of the vortex-antivortex network remained very stable. Later, the instrument configuration was switched to observe the Co over-layer. What was seen confirmed the team’s predictions: the Fe2O3 had ‘imprinted’ itself onto the adjacent metallic layer, forming tiny ferromagnetic vortices/antivortices exactly on top of the antiferromagnetic counterparts (Fig. 2). But – one may ask – what happens at the exact centre of the vortex? Once again, the power of analogy – helped by powerful finite-element simulations – provided the answer. The analogy here is with the ‘eye of the storm’ in a hurricane: whereas throughout the storm the wind whirls parallel to the ground, in the eye the flow is downwards towards the ground, whence the high pressure and clear skies. Likewise, at the centre of a ferromagnetic vortex, the spins are expected to lift out of the plane of the film, forming a topological structure known as a 'meron' (Fig. 3). Hints of 'meron' cores could be seen in the data, although the resolution of the measurements was not quite sufficient to confirm them unambiguously. Finite-element simulations confirmed that 'merons' with very small cores (10 nm) should form in these conditions. If corroborated by higher-resolution data, the existence of 'merons' would be extremely exciting; a 'meron' ‘core’ would in effect act as an extremely small memory bit, which would be topologically protected against thermal fluctuations by the surrounding vortex. Further beamtime at Diamond has been allocated for a new experimental campaign to control the density of magnetic vortices, and to investigate their presence in other materials and architectures.

Prof Paolo G. Radaelli, University of Oxford, p.g.radaelli@physics.ox.ac.uk

Diamond Light Source is the UK's national synchrotron science facility, located at the Harwell Science and Innovation Campus in Oxfordshire.

Copyright © 2022 Diamond Light Source

Diamond Light Source Ltd

Diamond House

Harwell Science & Innovation Campus

Didcot

Oxfordshire

OX11 0DE

Diamond Light Source® and the Diamond logo are registered trademarks of Diamond Light Source Ltd

Registered in England and Wales at Diamond House, Harwell Science and Innovation Campus, Didcot, Oxfordshire, OX11 0DE, United Kingdom. Company number: 4375679. VAT number: 287 461 957. Economic Operators Registration and Identification (EORI) number: GB287461957003.