____________________________________

Industrial Liaison Group:

Tel: +44 (0) 1235 778797

E-mail: [email protected]

Zinc oxide (ZnO) is a highly desirable multifunctional material possessing superior electronic, structural and morphological properties which also exhibits high chemical stability, a broad range of radiation absorption and high photostability. For this reason, ZnO is used in n-type semiconductors, solar cells, photocatalysts, sensing materials and antiseptic additive compounds.

Many believe that the defects present in ZnO’s structure are a key factor in influencing aspects of its performance and control of specific defect types could be used to enhance its functionality.

Defects in the ZnO structure are complex and hard to control during synthesis; they can influence both its chemical and physical performance. To study ZnO, scientists therefore need to use advanced characterisation techniques to help monitor changes in both local site symmetries and defective structures of ZnO. The results of this study will help scientists to understand the multifunctional properties and performance of ZnO.

A collaboration of scientists from Johnson Matthey, UCL, and Diamond carried out an in situ Zn K-edge experiment on B18 beamline using both extended X-ray absorption fine structure spectroscopy (EXAFS) and X-ray diffraction (XRD) via a controlled thermal decomposition of zinc peroxide (ZnO2).

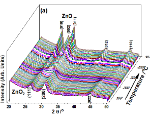

Respective in situ EXAFS and XRD datasets were collected in a combined time of less than one minute. This rapid time resolution allowed scientists to determine the pathway for the conversion of ZnO2 to a defective ZnO, and then an ordered ZnO material, in an air atmosphere at temperatures up to 500˚C.

By combining two techniques with both a short-range order of sensitivity (EXAFS) and a long-range order of crystallinity detection (XRD) under in situ conditions, the team were able to acquire high quality data, enabling them to determine the pathway for the thermal decomposition of ZnO2 to ZnO. Combining these results with those from thermogravimetric analysis (TGA), the team were able to identify a region where amorphous or very poorly crystalline ZnO solid is formed and monitor the defects forming in the ZnO structure.

"Johnson Matthey through our research efforts has developed an in depth understanding of zinc oxide materials properties under industrially related conditions. The ability to probe with fast time resolution at multi-length scales via in situ combined diffraction and spectroscopy at Diamond B18 has proven an essential component to this process.”

Dr Tim Hyde, Johnson Matthey

.png)

Diamond Light Source is the UK's national synchrotron science facility, located at the Harwell Science and Innovation Campus in Oxfordshire.

Copyright © 2022 Diamond Light Source

Diamond Light Source Ltd

Diamond House

Harwell Science & Innovation Campus

Didcot

Oxfordshire

OX11 0DE

Diamond Light Source® and the Diamond logo are registered trademarks of Diamond Light Source Ltd

Registered in England and Wales at Diamond House, Harwell Science and Innovation Campus, Didcot, Oxfordshire, OX11 0DE, United Kingdom. Company number: 4375679. VAT number: 287 461 957. Economic Operators Registration and Identification (EORI) number: GB287461957003.