____________________________________

Industrial Liaison Group:

Tel: +44 (0) 1235 778797

E-mail: industry@diamond.ac.uk

Indonesia is one of the largest suppliers of palm oil in the world, producing 42 million tonnes in 20181. It is also experiencing an increase in car usage, coupled with a growth in imports of fuel.

To overcome this problem, the Indonesian government is driving a move to biofuels. Until recently the fresh fruit bunch from palm oil has successfully been used, however the empty fruit bunch (EFB) and palm kernel shell (PKS) provide a more sustainable source of lignocellulose, a key component in second generation biofuel production.

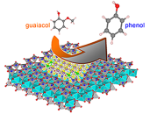

One prospective method for the biofuel production is conversion of lignocellulose into bio-oil via fast pyrolysis and then upgrading the bio-oil over a catalyst, to remove oxygen. However, the existing alumina-based and noble metal catalysts still suffer from catalyst deactivation due to carbon deposition and metal leaching.

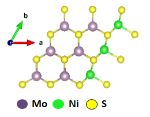

A bentonite-based catalyst, NiMoS2/Al-PILC, developed by the Indonesian Institute of Sciences (LIPI) shows the potential application for biofuel production with its ability to achieve a high degree of deoxygenation (DOD) up to to 65% using bio-oil derived lignocellulose feedstock - a 15% improvement on the commercial NiMoS2/Al2O3 catalyst. Unfortunately, the active sites responsible for this effective hydrodeoxygenation (HDO) process and the exact role of aluminum pillared clay (Al-PILC) have not been well understood.

Another concern about the catalyst’s sensitivity to air to make it viable for commercial use remains unanswered. As analysis using diffraction techniques is impossible due to the non-crystalline nature of the catalyst, X-ray Absorption Spectroscopy (XAS) is the only feasible technique to understand its structure.

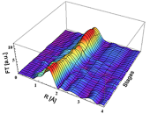

LIPI and Diamond scientists conducted in situ XAS measurement at Mo K-edge, Ni K-edge, and Co K-edge. They were able to track down the gradual transition of the oxide-to-sulfide transformation of NiMoS2 and CoMoS2 catalysts. When directly exposed to steady air flow for one hour, both catalysts experienced mild oxide phase MoOx formation that could be easily eliminated by re-sulfidation treatment.

By fitting Extended X-ray Absorption Fine Structure (EXAFS) data with density functional theory (DFT) models, the atom arrangement and distribution of promoter atoms Ni and Co in the catalyst can be fully determined. The findings suggest that the 2D structure of NiMoS2and CoMoS2 adsorbed on Al-PILC might have an irregular structure instead of a regular hexagonal structure. Moreover, the result also indicates that no significant parts of Ni and/or Co atoms are oxidised during air exposure.

Using synchrotron techniques at Diamond, scientists were able to study the evolution of a NiMoS2/PILC catalyst during activation. By understanding the structure, we can design much more effective catalysts, able to convert waste produce from palm oil into sustainable biofuels.

1 https://reut.rs/2EvVRyT

“Access to world-class synchrotron XAS at Diamond has helped us to elucidate the exact structural geometry of our catalysts, not possible with lab-based diffraction techniques. This scientific knowledge is essential to unravel the complexity of chemical reactions that occur between bio-oil and the catalysts. The current work also demonstrates our first successful attempt to interpret EXAFS data using computational generated models.” Dr Ferensa Oemry, Indonesian Institute of Sciences (LIPI)

Diamond Light Source is the UK's national synchrotron science facility, located at the Harwell Science and Innovation Campus in Oxfordshire.

Copyright © 2022 Diamond Light Source

Diamond Light Source Ltd

Diamond House

Harwell Science & Innovation Campus

Didcot

Oxfordshire

OX11 0DE

Diamond Light Source® and the Diamond logo are registered trademarks of Diamond Light Source Ltd

Registered in England and Wales at Diamond House, Harwell Science and Innovation Campus, Didcot, Oxfordshire, OX11 0DE, United Kingdom. Company number: 4375679. VAT number: 287 461 957. Economic Operators Registration and Identification (EORI) number: GB287461957003.