____________________________________

Industrial Liaison Group:

Tel: +44 (0) 1235 778797

E-mail: industry@diamond.ac.uk

Luxfer Gas Cylinders have been manufacturing high-pressure self-contained breathing apparatus (SCBA) and life-support cylinders for fire-fighters and first-responders since the early 1970s. Cylinders are required to be increasingly lightweight, efficient and safe storage solutions. Advanced carbon fibre-wrapped aluminium construction methods and a fabrication process called autofrettage aim to reduce weight and increase maximum working pressures of cylinders. However, since cylinders can be exposed to demanding conditions, it is critical that their structural integrity be maintained.

Luxfer wanted to characterise stress states inside cylinders both as-manufactured and after being subjected to a standard drop test, the most common damage mechanism. This required cylinders to be measured in a non-destructive manner so that the same samples could be used for both tests, thus allowing Luxfer to understand the effect of autofrettage pressure more accurately.

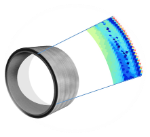

A team of material engineers from Luxfer, University of Southampton and Diamond used energy dispersive diffraction (EDX) performed on beamline I12 to characterise the autofrettage process and evaluate the effect of impact damage on gas cylinders. The high energy polychromatic X-rays available on I12 can penetrate through significant thicknesses of samples, allowing measurements that would not be feasible using lab-based diffraction equipment.

Pioneering diffraction measurements carried out at Diamond allowed direct measurement of stress states inside as-manufactured Luxfer SCBA cylinders. Results were compared with lab-based micro-computed tomography and current finite element models, providing base information to improve current models. The combination of imaging and diffraction provides a powerful set of tools to evaluate damage-caused impact.

“Luxfer Gas Cylinders are delighted with the excellent information obtained as a result of our collaboration with Diamond Light Source and the University of Southampton. The results achieved will assist greatly in the development of our lightweight composite cylinders”

Dr Warren Hepples, Luxfer Gas Cylinders Europe

Diamond Light Source is the UK's national synchrotron science facility, located at the Harwell Science and Innovation Campus in Oxfordshire.

Copyright © 2022 Diamond Light Source

Diamond Light Source Ltd

Diamond House

Harwell Science & Innovation Campus

Didcot

Oxfordshire

OX11 0DE

Diamond Light Source® and the Diamond logo are registered trademarks of Diamond Light Source Ltd

Registered in England and Wales at Diamond House, Harwell Science and Innovation Campus, Didcot, Oxfordshire, OX11 0DE, United Kingdom. Company number: 4375679. VAT number: 287 461 957. Economic Operators Registration and Identification (EORI) number: GB287461957003.