____________________________________

Industrial Liaison Group:

Tel: +44 (0) 1235 778797

E-mail: industry@diamond.ac.uk

Only a very small proportion of the surfactant used in cleaning products is actually needed to provide the cleaning function. The majority of the surfactant used in formulations is added as a rheological modifier (thickener). Many surfactants are derived from petrochemicals so finding alternative and sustainable sources of ingredients with similar physicochemical properties is an important formulation challenge for consumer products manufacturers.

Already finding uses in medical applications, cellulose has been proposed as a rheological modifier suitable for a wide range of formulation types. Cellulose is in many ways a perfect formulation ingredient. As a “waste” product of other processes, it is abundant and non-food competitive. It is not derived from petrochemicals and is renewable, sustainable and low cost. However, while it represents huge potential as a formulation thickener, its gelation behaviour is not well understood and therefore cannot be accurately controlled.

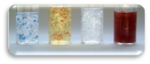

Developing novel cellulose-based formulation materials is the goal of a collaboration in Functional, Renewable and Sustainable Materials with project partners including Unilever, Croda Speciality Chemicals, Rockwood Additives, University of Bath, University of Liverpool and the National Non-Food Crop Centre. Researchers used Diamond (I22) to investigate gel microstructure using a biodegradable and easily dispersible form of cellulose. The gels were investigated under a range of formulation conditions including varying salt concentration, variable salt types, surfactant types and pH levels. Changes in the structure of the gel were also monitored in the presence of other formulation ingredients, for example perfumes and low molecular weight alcohols.

Understanding and controlling the behaviour of cellulose in formulations represents an opportunity to respond to consumer demand for the increased use of sustainable resources, a cost saving for the total product to pay for a new ingredient and for the development of innovative new products.

“SAXS experiments at Diamond have enabled us to probe the gelation behaviour of oxidised cellulose nanofibres to explain gel formation under a range of formulation conditions. We have demonstrated that oxidised cellulose nanofibres show great promise for future use as sustainable and low cost formulation ingredients.”

Dr Karen Edler, University of Bath

Diamond Light Source is the UK's national synchrotron science facility, located at the Harwell Science and Innovation Campus in Oxfordshire.

Copyright © 2022 Diamond Light Source

Diamond Light Source Ltd

Diamond House

Harwell Science & Innovation Campus

Didcot

Oxfordshire

OX11 0DE

Diamond Light Source® and the Diamond logo are registered trademarks of Diamond Light Source Ltd

Registered in England and Wales at Diamond House, Harwell Science and Innovation Campus, Didcot, Oxfordshire, OX11 0DE, United Kingdom. Company number: 4375679. VAT number: 287 461 957. Economic Operators Registration and Identification (EORI) number: GB287461957003.