____________________________________

Industrial Liaison Group:

Tel: +44 (0) 1235 778797

E-mail: industry@diamond.ac.uk

With 27% of global energy consumption occurring in the residential sector, harvesting and storing thermal energy is increasingly important.

A promising technology is based on phase-change materials (PCMs) that absorb or release large amounts of heat when they change state, e.g. from solid to liquid.

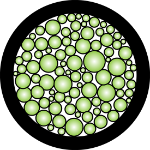

PCMs incorporated into building materials could remove excess heat during the day and release it at night, with minimum carbon emissions. One approach in stabilising PCMs for use is nanoscale confinement in core-shell structures.

A team of researchers from Aalto University in Finland has been exploring simple, low-cost, and scalable colloidal synthesis methods to produce hybrid nanomaterials from renewable resources. They developed a one-pot fabrication methodology for the preparation of fatty acid core-shell particles stabilised by softwood kraft lignin. Lignin, a sustainable by-product of the paper industry, is a highly abundant complex biopolymer particularly in wood and bark. Understanding the microstructures formed through the novel synthesis method is critical to the success of the project.

The team from Aalto University made use of Diamond’s mail in small angle X-ray scattering (SAXS) service, shipping the samples to Diamond where Industrial Liaison staff performed the SAXS experiments using beamline B21. The data were reduced and with a fast turnaround time, were sent back to the team for further analysis. The SAXS data were used in combination with other techniques to fully characterise the materials.

The SAXS analysis has significantly improved the understanding of the formation mechanism and packing patterns of various lignin morphologies, suggesting beneficial stability for cycling over a prolonged period. The resulting hybrid nanocapsules show outstanding performance as phase change materials, paving the way for sustainable expansion of PCMs in thermal energy storage applications. Porous lignin nanocapsules could also be explored as catalyst supports and gas separation materials.

"We were very satisfied with the levels of cooperation and communication with the staff at Diamond in all stages of the process from the sample send-in service to the delivery of data for their detailed analyses.” Assistant Prof Mika Sipponen (pictured), Stockholm University and Prof Monika Österberg, Aalto University

“The SAXS experiments allowed us to see the structure of the particles in their native state, that is, in the aqueous solution and without drying. In this way, we could ensure that what we saw in the electron microscopy images was indeed the real structure of the samples.” Dr Paavo Penttilä, Aalto University

Click on the link below to download a copy of the case study.

|

| DOWNLOAD |

Diamond Light Source is the UK's national synchrotron science facility, located at the Harwell Science and Innovation Campus in Oxfordshire.

Copyright © 2022 Diamond Light Source

Diamond Light Source Ltd

Diamond House

Harwell Science & Innovation Campus

Didcot

Oxfordshire

OX11 0DE

Diamond Light Source® and the Diamond logo are registered trademarks of Diamond Light Source Ltd

Registered in England and Wales at Diamond House, Harwell Science and Innovation Campus, Didcot, Oxfordshire, OX11 0DE, United Kingdom. Company number: 4375679. VAT number: 287 461 957. Economic Operators Registration and Identification (EORI) number: GB287461957003.