___________________________________

Industrial Liaison Group:

Tel: +44 (0) 1235 778797

E-mail: [email protected]

In China, bamboo is a symbol of longevity and vitality, able to survive the hardest natural conditions and remain green all year round. In a storm, bamboo stems bend but do not break, representing the qualities of durability, strength, flexibility and resilience1.

Bamboo is a traditional construction material in Asia. Its strength and flexibility arise from its hollow stems (‘culms’) made from distinct material components. The solid outer shell of the culm is made primarily from longitudinal fibres. A higher density at the outer wall makes it stronger than the inner regions, and results in remarkable stiffness and flexural strength. Running through the centre of bamboo stem are parenchyma cells that store and channel the plant’s nutrients.

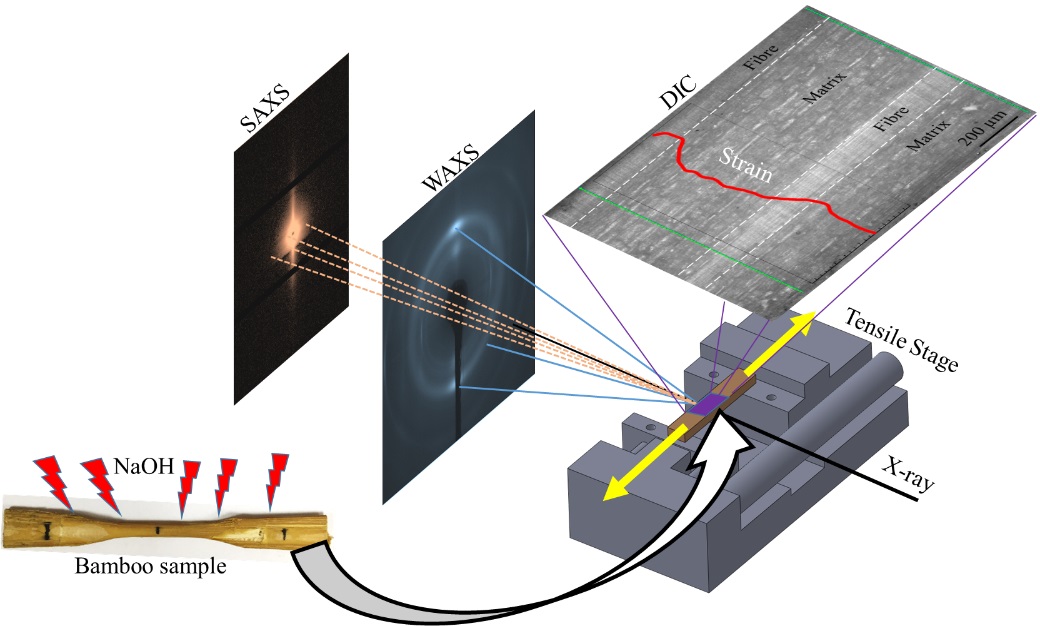

Figure 1: A graphical representation of the experiment at Diamond's B16 beamline.

At the micro-/nano-scale both the fibres and the matrix contain cellulose nano-fibrils of the same type. However, the structural arrangement of the two materials result in contrasting mechanical properties. Individual fibres may reach a strength of 900 MPa, whilst the matrix can only resist about 50 MPa. There is also a considerable difference in their elastic properties, with the fibres being much stiffer than the matrix.

Bamboo is often treated with alkaline solutions, to modify these properties. Alkaline treatments can turn this rapidly renewable and low-cost resource into soft textiles, and extract fibres to be used in composite materials or as biomass for fuel.

A team of researchers from Professor Alexander M. Korsunsky’s Multi-Beam Lab for Engineering Microscopy (MBLEM) at the University of Oxford used Diamond's Test Beamline B16 to study the effect of sodium hydroxide (NaOH) on the elastic properties of bamboo. Their work, published in Acta Biomaterialia, presents a detailed analysis of the deformation mechanisms taking place in bamboo fibres and matrix.

On beamline B16, the team used Wide and Small Angle X-ray Scattering (WAXS and SAXS) during in situ tensile deformation experiments to monitor the mechanical response of the whole bamboo ‘composite’ material, and specifically its fibrous content. WAXS provided an accurate assessment of the deformation in the crystalline constituents at the lattice scale, while SAXS enabled the study of the material “matrix” structures with the range of dimensions of tens of nanometres. A coupled in situ Optical Microscopy (OM) and Digital Image Correlation (DIC) analysis was carried out during tensile testing to evaluate the deformation taking place at the micron scale.

Figure 2: Dr Enrico Salvati on the B16 beamline.

Figure 2: Dr Enrico Salvati on the B16 beamline.

The results confirmed that the elastic modulus of bamboo fibres experiences a gradual increase with the alkalinity up to 20% NaOH. However, a 25% NaOH solution reduced the elastic modulus by 37%.

Lead author Dr Enrico Salvati explains: “Our analysis using the combination of in situ synchrotron scattering techniques with an optical method allowed detailed evaluation of the mechanical properties modification induced by NaOH treatments. Given the wide range of applications, these results are certain to motivate further investigations.”

Professor Alexander Korsunsky adds: “This study illustrates how multi-scale deformation analysis helps shed light on the properties of bamboo, a fascinating example of Nature’s hierarchically structured materials.”

Salvati E et al. Multiscale analysis of bamboo deformation mechanisms following NaOH treatment using X-ray and correlative microscopy. Acta Biomaterialia (2018). DOI:10.1016/j.actbio.2018.03.050.

Diamond Light Source is the UK's national synchrotron science facility, located at the Harwell Science and Innovation Campus in Oxfordshire.

Copyright © 2022 Diamond Light Source

Diamond Light Source Ltd

Diamond House

Harwell Science & Innovation Campus

Didcot

Oxfordshire

OX11 0DE

Diamond Light Source® and the Diamond logo are registered trademarks of Diamond Light Source Ltd

Registered in England and Wales at Diamond House, Harwell Science and Innovation Campus, Didcot, Oxfordshire, OX11 0DE, United Kingdom. Company number: 4375679. VAT number: 287 461 957. Economic Operators Registration and Identification (EORI) number: GB287461957003.