___________________________________

Industrial Liaison Group:

Tel: +44 (0) 1235 778797

E-mail: [email protected]

.2020-02-17-11-01-44.png) X-ray imaging allows detailed information to be gathered from below the surface of a material through either full-field imaging, where the whole sample is illuminated, or through scanning, where the beam is focused to a small spot which is scanned across the sample. The high intensity and energy of the synchrotron X-rays produced at Diamond make it possible to image a much larger range of materials and sample thicknesses than conventional X-ray sources, and the brilliance of the synchrotron source produces very high-resolution images. The parallel, monochromatic beam enhances the image quality beyond what is possible with laboratory techniques and in a non-destructive manner. These high intensity X-rays also permit very fast measurements for high speed imaging experiments, monitoring changes in the sample during real-time, in situ experiments.

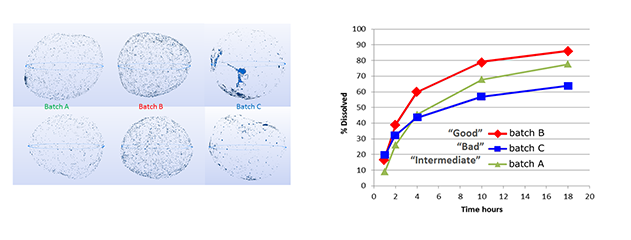

X-ray imaging allows detailed information to be gathered from below the surface of a material through either full-field imaging, where the whole sample is illuminated, or through scanning, where the beam is focused to a small spot which is scanned across the sample. The high intensity and energy of the synchrotron X-rays produced at Diamond make it possible to image a much larger range of materials and sample thicknesses than conventional X-ray sources, and the brilliance of the synchrotron source produces very high-resolution images. The parallel, monochromatic beam enhances the image quality beyond what is possible with laboratory techniques and in a non-destructive manner. These high intensity X-rays also permit very fast measurements for high speed imaging experiments, monitoring changes in the sample during real-time, in situ experiments.An imaging technique called X-ray (computed) tomography allows creation of three-dimensional reconstructions of the internal sample volume from a series of two-dimensional projections taken at different orientations. By creating a virtual image using tomographic reconstruction, it is possible to view any cross-section of the virtual image at any angle.

Diamond Light Source is the UK's national synchrotron science facility, located at the Harwell Science and Innovation Campus in Oxfordshire.

Copyright © 2022 Diamond Light Source

Diamond Light Source Ltd

Diamond House

Harwell Science & Innovation Campus

Didcot

Oxfordshire

OX11 0DE

Diamond Light Source® and the Diamond logo are registered trademarks of Diamond Light Source Ltd

Registered in England and Wales at Diamond House, Harwell Science and Innovation Campus, Didcot, Oxfordshire, OX11 0DE, United Kingdom. Company number: 4375679. VAT number: 287 461 957. Economic Operators Registration and Identification (EORI) number: GB287461957003.