___________________________________

Industrial Liaison Group:

Tel: +44 (0) 1235 778797

E-mail: industry@diamond.ac.uk

Synchrotron imaging provides powerful visualisations of a wide range of samples, reaching far beyond the surface of a material. It can reveal the internal or hidden components of a sample, without having the harsh destructive effects of other research techniques. It can probe the interior structure of materials, down to a molecular level to address challenges in areas as wide as:

♦ Cell biology ♦ Food science ♦ Chemical identification ♦ Molecular identification ♦ Environmental science ♦ Soft matter ♦ Engineering materials

At Diamond we have a wide range of imaging techniques that can be used to meet different requirements. To get a broader insight into how imaging works, take a look at our article.

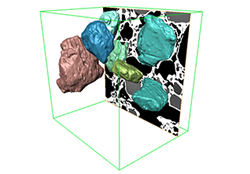

X-ray imaging at Diamond offered researchers a rapid, non-invasive and quantifiable method to study a range of Gas Particulate Filters samples to assess the impact of different engine oil formulations. To find out more, read our case study.

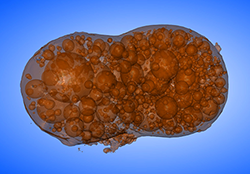

X-ray imaging allowed scientists at Unilever and the University of Manchester to study how processing conditions and ingredients affect the taste of ice cream. To find out more read our case study.

Imperial College used X-ray tomography to understand how and why osteoporosis treatment using alondronate might cause stress fractures. To find out more read our case study.

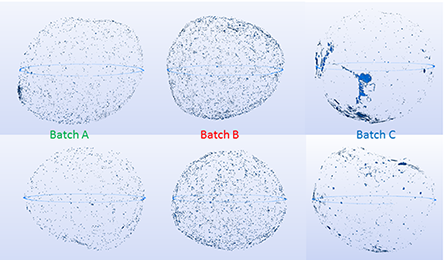

High resolution X-ray tomography measurements enabled beads from 3 different production batches to be studied by scientists at Pfizer, to distinguish porosity differences between the different production batches. This is key in the development of controlled-release drugs. To find out more, read our case study.

Scientists from the University of Bristol used Tomography imaging and micro-fluorescence measurements at Diamond to understand the physical and chemical nature of the radioactive particles from Fukushma and determine their long-term environmental fate and health risks. To find out more, read our case study.

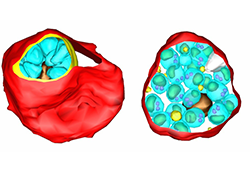

This collaborative study involved using mapping techniques, including cryo-soft X-ray tomography, to visualise red blood cells infected with a species of Plasmodium. By understanding egress, a critical stage of infection, scientists would be able to develop new medicines. To find out more, read our case study.

X-ray radiography allowed scientists to observe a variety of in situ process conditions to uncover key mechanisms and interactions during Laser Additive Manufacturing. The insight will lead to optimum conditions to improve the quality of products of the future. To find out more, read our case study.

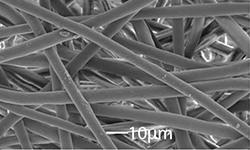

Fast in-line phase-contrast tomography was used by a collaboration of scientists to understand the failure mechanisms of electrospun fibres, used in healthcare to resemble the macromolecular structure of many tissue matrices. To find out more, read our case study.

Below are details of some of our core instruments for Imaging.

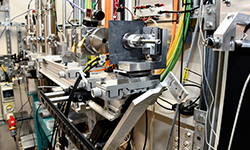

I12: Joint Engineering, Environment and Processing (JEEP) beamline is a high-energy beamline principally for Material Science, Engineering and Processing Science. The instrument's main focus is to allow in situ studies of samples in as close as possible real-world environments using imaging, tomography, diffraction and small-angle scattering. It is well suited to study large or dense objects and offers a unique sample and environment installation facility for weights up to 2000kg. Find out more.

I12: Joint Engineering, Environment and Processing (JEEP) beamline is a high-energy beamline principally for Material Science, Engineering and Processing Science. The instrument's main focus is to allow in situ studies of samples in as close as possible real-world environments using imaging, tomography, diffraction and small-angle scattering. It is well suited to study large or dense objects and offers a unique sample and environment installation facility for weights up to 2000kg. Find out more.

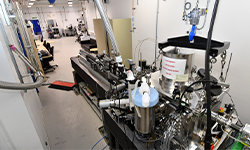

I13 - X-ray imaging and coherence is Diamond's longest beamline, dedicated to imaging, tomographic and coherence experiments across the biological, medical, geological, material, engineering and archeological sciences. Find out more.

I13 - X-ray imaging and coherence is Diamond's longest beamline, dedicated to imaging, tomographic and coherence experiments across the biological, medical, geological, material, engineering and archeological sciences. Find out more.

B24 - Correlative cryo-imaging beamline is a full-field transmission microscope at Diamond designed specifically to meet the rising demand for tomographic imaging of biological specimens under near physiological conditions. Find out more

B24 - Correlative cryo-imaging beamline is a full-field transmission microscope at Diamond designed specifically to meet the rising demand for tomographic imaging of biological specimens under near physiological conditions. Find out more

To find out more about Imaging at Diamond, or to discuss potential industrial applications, please complete an enquiry form or contact the Industrial Liaison team on 01235 778797. You can keep in touch with the latest development by following us on Twitter @DiamondILO or LinkedIn.

Diamond Light Source is the UK's national synchrotron science facility, located at the Harwell Science and Innovation Campus in Oxfordshire.

Copyright © 2022 Diamond Light Source

Diamond Light Source Ltd

Diamond House

Harwell Science & Innovation Campus

Didcot

Oxfordshire

OX11 0DE

Diamond Light Source® and the Diamond logo are registered trademarks of Diamond Light Source Ltd

Registered in England and Wales at Diamond House, Harwell Science and Innovation Campus, Didcot, Oxfordshire, OX11 0DE, United Kingdom. Company number: 4375679. VAT number: 287 461 957. Economic Operators Registration and Identification (EORI) number: GB287461957003.