___________________________________

Industrial Liaison Group:

Tel: +44 (0) 1235 778797

E-mail: industry@diamond.ac.uk

.jpg)

In work funded by the CARENA project, scientists from the Industrial Liaison Team at Diamond have created a capillary-based sample environment; a generic plug-flow reactor used on powder samples, which provides ideal conditions for mimicking catalytic reactions. The sample environment has been successfully commissioned and is now extensively used by users at Diamond Light Source. The dedicated in situ cell covers wide range of catalytic processes and the generic design of the sample environment is not only suitable for time-resolved, in situ experiments using Quick EXAFS on beamline B18, but the modular design of the gas system and integration within the EPICS make it compatible with other sample environments across other beamlines at Diamond. The work has recently been published in conference proceedings here.

X-ray Absorption Spectroscopy (XAS) is a synchrotron-based technique which has been applied extensively in the field of heterogeneous catalysis. A particular strength of this measurement is that the penetration depth of X-rays makes possible studies of materials under the conditions of their use, including high temperatures, pressure and reactive atmospheres. Moreover, XAS can be applied with other complementary techniques such as X-ray Diffraction (XRD), UV-visible and Raman spectroscopy, XRD with Raman spectroscopy, Raman/UV-visible combined with Small Angle X-ray Scattering (SAXS) and Wide Angle X-ray Scattering (WAXS). These technique partnerships open up a wide range of research possibilities; for example, the structure of a catalysts can be determined simultaneously with the measurement of the catalytic performance using mass spectrometry.

The possibility of performing time-resolved, in situ experiments and combining them with other techniques has led to the design of different in situ reaction cells that can mimic conditions close to real industrial environments. In this particular case, the approach was to deliver a generic capillary-based reaction cell, with the temperature and gas distribution capabilities built within the Experimental Physics and Industrial Control system (EPICS) interface commonly used at synchrotron facilities, which enables the user to remotely follow in situ gas-solid chemical reactions.

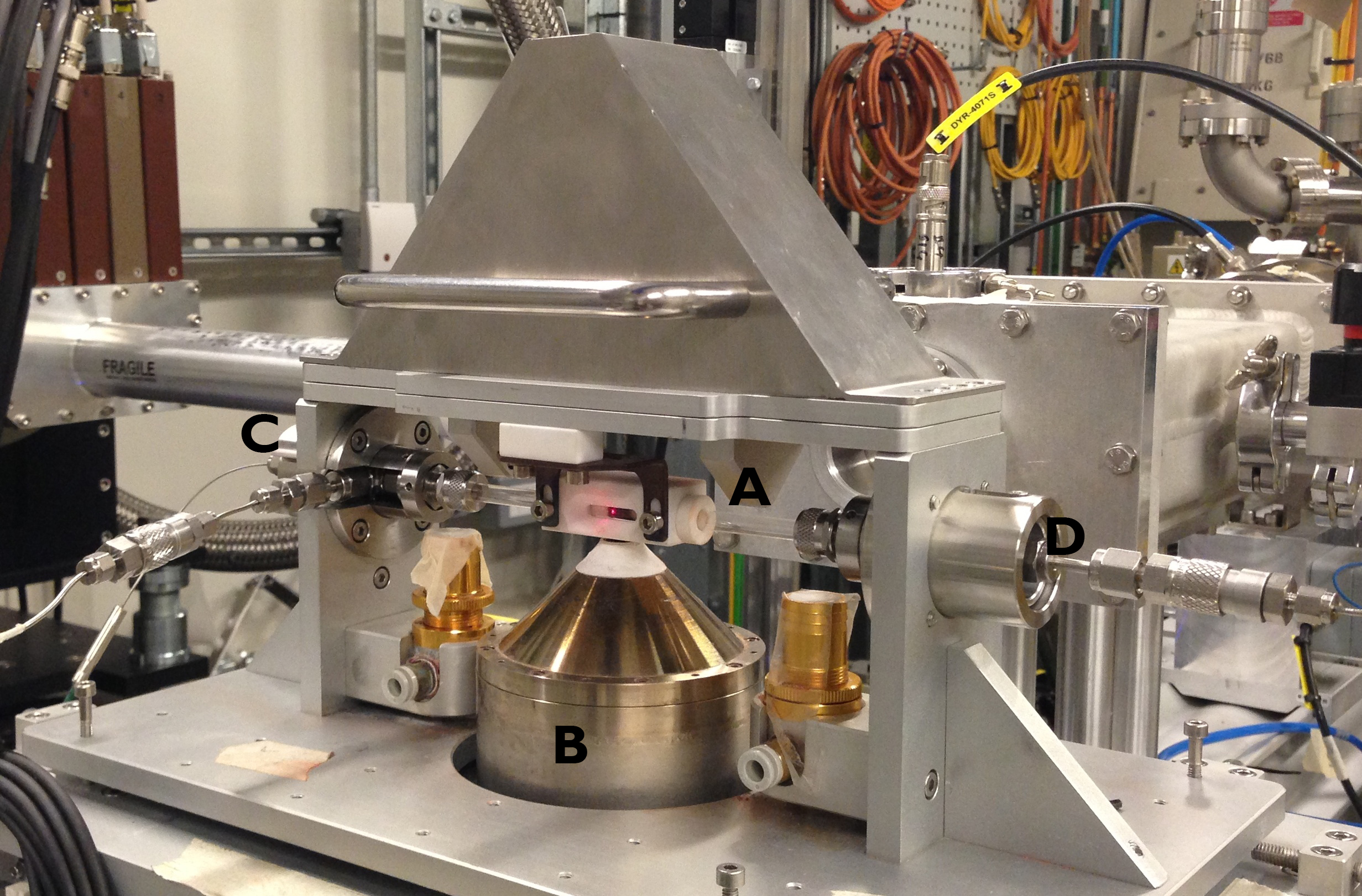

The gas flow sample environment created allows XAS measurements to be performed in both transmission and fluorescence modes. This is achieved by the use of packed-bed quartz capillary-tube reactor supported on a stainless steel frame (Fig. 1).

Heating the sample

The capillary is heated by a hot air blower with a controlled air flow and the temperature measured by a thermocouple at the heating element in order to control the temperature of the heating ramp. The biggest advantage of using a hot air blower instead of other heating sources is that it provides more space in the vicinity of the sample, giving access to additional complementary probes (XRD, Raman, IR). A ceramic block around the sample position allows for the achievement of isothermal conditions. This set up allows for heating of the reaction cell up to 1123 K.

The gas system

The gas system consists of Alicat mass flow controllers, two VICI microelectric-actuated 8-ports dead-end valves, and one VICI air-actuated 4-ports 2-position valve, which drives the final gas switch before the gas feedstock is injected to the reaction cell. The main reason for introducing an air-actuated valve as a driving gas switch to the reaction is that the response time of the switch for this valve is much quicker than the micro-electric actuated valves (ca. 100 ms). This feature is not so crucial when running Quick EXAFS experiments (time resolution of seconds). However, this sample environment has other applications for time-resolved studies on several beamlines where millisecond data collections are required.

All the gas and heating system devices are integrated with EPICS and all variables can be saved in the experimental file. The gas flow capillary-based cell was successfully commissioned on beamline B18 (core-EXAFS) at Diamond. It has since been widely used on a number of sessions on this beamline. Moreover, the gas distribution system has been effectively applied on various experiments at other beamlines at Diamond including I11, I12, B16 and B22.

We’re always happy to discuss any enquiries or talk about ways in which access to Diamond’s facilities may be beneficial to your business so please do give us a call on 01235 778797 or send us an e-mail. You can keep in touch with the latest development by following us on Twitter @DiamondILO orLinkedIn

A.B. Kroner, K.M.H. Mohammed, M. Gilbert, G. Duller, L. Cahill, P. Leicester, R. Woolliscroft, E.J. Shotton, A Flexible Gas Flow Reaction Cell for in situ X-Ray Absorption Spectroscopy Studies, 030014 DOI: 10.1063/1.4952837

Diamond Light Source is the UK's national synchrotron science facility, located at the Harwell Science and Innovation Campus in Oxfordshire.

Copyright © 2022 Diamond Light Source

Diamond Light Source Ltd

Diamond House

Harwell Science & Innovation Campus

Didcot

Oxfordshire

OX11 0DE

Diamond Light Source® and the Diamond logo are registered trademarks of Diamond Light Source Ltd

Registered in England and Wales at Diamond House, Harwell Science and Innovation Campus, Didcot, Oxfordshire, OX11 0DE, United Kingdom. Company number: 4375679. VAT number: 287 461 957. Economic Operators Registration and Identification (EORI) number: GB287461957003.