___________________________________

Industrial Liaison Group:

Tel: +44 (0) 1235 778797

E-mail: [email protected]

Persuading people about the advantages of nuclear energy is often a challenge as most people remember the fall-out surrounding disasters such as Chernobyl and Fukushima; there is also an argument against how sustainable this form of energy is, especially in terms of how nuclear waste is handled, but could nuclear energy be the best option to meet our growing energy needs as well as helping us to meet our green agenda?

It’s interesting to look back at the evolution of the UK’s energy supply to see how we’ve arrived at our current situation. Traditionally the UK was very much wedded to fossil fuels with a huge amount of mining taking place across the country to produce coal. This situation started to change in the 1980s when there was a concerted attempt to move away from fossil fuels. At this time we saw a decline in coal production in favour of gas, which was also used in the generation of electricity.

situation. Traditionally the UK was very much wedded to fossil fuels with a huge amount of mining taking place across the country to produce coal. This situation started to change in the 1980s when there was a concerted attempt to move away from fossil fuels. At this time we saw a decline in coal production in favour of gas, which was also used in the generation of electricity.

In 2019 domestic production was sufficient to meet around 50% of demand; however, since 2000 domestic production has declined by 65% and we have since relied upon imports from Scandinavia and the middle east to appease our growing consumption.

Over the last 20 years, the UK has been investing heavily in renewable energy, firstly through hydroelectric generation then through wind power, a resource that let’s face it, we have in abundance in the UK!

Over the last 20 years, the UK has been investing heavily in renewable energy, firstly through hydroelectric generation then through wind power, a resource that let’s face it, we have in abundance in the UK!

Other sources include biofuels (the UK’s second largest source of renewable energy at 12%), solar and hydro-power, but do any of these produce sufficient energy to meet our ever increasing needs? And are they sustainable? (only 9% of renewable fuel supplied to the UK was produced from UK original feedstocks.)

This is where nuclear energy is seen as an attractive option. It is considered an energy dense technology providing large amounts of power but requiring relatively small areas of land. It has the capacity to reduce system costs at low levels of emissions, so would enable greener energy production.

large amounts of power but requiring relatively small areas of land. It has the capacity to reduce system costs at low levels of emissions, so would enable greener energy production.

Not surprisingly, therefore, the UK government intends to invest in nuclear energy more heavily over the coming years. With the commitment to carbon zero by 2050, and the move towards electric vehicles, demand for alternative forms of energy is likely to grow significantly, but how do we get to this point?

Currently the UK generates about 20% of its electricity from nuclear but almost half of the current nuclear capacity is to be retired by 2025 – that’s really not far off! This means developing new nuclear facilities.

The UK government has committed to providing £385 million to build the next generation of nuclear technology, with an additional £170 million to fund a programme on Advanced Modular Reactors (AMRs) which have a much smaller carbon footprint and require much lower capital investment. An ambitious plan has been laid out for a quarter of Britain’s energy to be supplied from nuclear plants by 2025 and eight sites across Britain have been chosen as locations for new nuclear stations.

Most of the operational nuclear plants in the UK have been going since 1970s and 1980s so the materials used are pretty old now. In order to decommission these sites, there needs to be a comprehensive clean up mission – this means assessing the integrity of the materials in place, extending the life of others, and recycling materials such as spent fuel where possible.

The estimated cost for this clean-up is an astounding £126BN over the next 120 years. Not surprisingly the government has challenged the sector with the task of reducing this cost by 20% This is driving technological innovation to find a solution for the way in which nuclear material is processed. It’s a long battle, but there have been some giant steps in taking this forward.

By understanding the behaviour of materials from existing nuclear sites, we c an inform the development of advanced materials for use in newly commissioned facilities. So what sort of standards do these materials need to reach and what qualities are imperative for these safe use?

an inform the development of advanced materials for use in newly commissioned facilities. So what sort of standards do these materials need to reach and what qualities are imperative for these safe use?

Well, these materials will be used over a large time span so need to be extremely durable, mechanically sound and maintain integrity over many years. The challenging environment in which they will be used also mean that their properties need to be stable when exposed to radiation. Any novel structural materials must be able to cope within extreme conditions without the mechanisms becoming brittle or succumbing to swelling and creep.

Fuel cladding is another area where research is prevalent. Cladding materials are integral to protecting the fuel and must therefore maintain structural integrity (no corrosion) both during normal operating conditions and also within accident scenarios. The fuel itself must not release fission products, must meet stringent thermal properties requirements, and must not chemically react with the cladding and coolant.

To design advanced materials that meet these properties requires a fundamental knowledge of the material microstructures and an understanding of how they react to radiation, both in the short-term, and over long durations. By observing the properties of these materials and tracking any defects that occur, scientists can start to develop more resistant / higher performance materials and obtain measurements to inform models to predict the long-term performance of these materials.

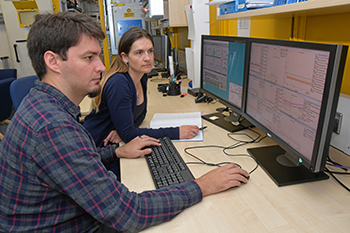

The Diamond synchrotron offers a plethora of unique properties, providing radiation of high brilliance, wide spectral range, tuneability, and well-defined time - space structure and coherence; ideally suited for advanced characterisation of materials. Research methods available at Diamond provide high elemental sensitivity, chemical speciation, time resolution, and 3D spatial resolution at the micrometre scale or below. The characterisation techniques are well suited to address the complex questions posed during the development and testing of new nuclear materials applied in the field of energy. The results can be used to understand the materials themselves and also to provide valuable information to inform the development of long-term predictive models.

Increasing fuel efficiency whilst retaining reactor safety

Zirconium alloys are well suited to the needs of cladding encapsulating nuclear fuel; however, in those mos t commonly used, such as Zircaloy-2, Zircaloy-4, M5TM and ZIRLOTM, they also include small amounts of iron which has been shown to increase corrosion resistance.

t commonly used, such as Zircaloy-2, Zircaloy-4, M5TM and ZIRLOTM, they also include small amounts of iron which has been shown to increase corrosion resistance.

In order to fully understand the long-term effectiveness of these materials, scientists needed to understand the mechanisms by which iron effects the oxidation and hydrogen pick up rate of thermally grown zirconium alloys. They also required further insights into the defect concentrations.

Scientists at the National Nuclear Laboratory applied a combination of X-ray Fluorescence (XRF) and Zr & Fe K-edge X-ray Absorption Near Edge Strucure (XANES) on I18 at Diamond to identify the zirconium and iron distribution, along with the chemical speciation in the oxide film on Zircaloy-4 fuel cladding material.

We have a dedicated industry specific team who are specialists in a range of different research techniques. They can guide and support you throughout your research. Please get in touch for further information and to find out how we can support your nuclear research.

Diamond Light Source is the UK's national synchrotron science facility, located at the Harwell Science and Innovation Campus in Oxfordshire.

Copyright © 2022 Diamond Light Source

Diamond Light Source Ltd

Diamond House

Harwell Science & Innovation Campus

Didcot

Oxfordshire

OX11 0DE

Diamond Light Source® and the Diamond logo are registered trademarks of Diamond Light Source Ltd

Registered in England and Wales at Diamond House, Harwell Science and Innovation Campus, Didcot, Oxfordshire, OX11 0DE, United Kingdom. Company number: 4375679. VAT number: 287 461 957. Economic Operators Registration and Identification (EORI) number: GB287461957003.