___________________________________

Industrial Liaison Group:

Tel: +44 (0) 1235 778797

E-mail: [email protected]

Today’s consumers are becoming increasingly discerning about the foods they choose to buy and the food industry is challenged with creating products that cater for a wide range of tastes and lifestyles – from healthy lifestyles through to more plant-based diets, and products to address food intolerances.

Food scares have pushed for improved quality control and traceability of food, and legislation in this industry continues to bring new challenges. Rising raw material costs around the world, sustainability and waste reduction have also added to challenges for the food industry, particularly for global supply chains.

Due to the competitive nature of this industry, brand loyalty is premium, requiring consistently high quality and an endless cycle of new product developments to meet consumer demands.

When it comes to perfecting the taste, texture and appearance of food, manufacturers are increasingly turning to research methods to create the optimal customer experience across multiple environments.

Innovation in these areas requires a good understanding of the science behind the product or process and access to the widest possible variety of research and development tools. Diamond Light Source's advanced characterisation facilities are actively supporting this innovation.

Diamond provides specialist analytical techniques that can be used by the food industry to characterise materials ranging from ingredients and formulations, packaging and food processing components through to agriculture.

The specialist facilities enable researchers to drill much deeper than an ordinary laboratory would allow, reaching atomic to microscale level. These characterisation tools provide rapid, detailed and actionable insight, using a number of techniques. These fall into three main technique classes:

Measuring the mineral content of wheat

Deficiencies in iron and zinc are affecting an increasing number of people worldwide due to the low intake and bioavailability of minerals from traditional diets based with little or no meat, fruit and vegetables. Using X-ray Spectroscopy at Diamond scientists at Rothamsted Research were able to investigate the distribution and complexation of mineral deposits in different varieties of grain to understand the digestibility of the wheat.

Deficiencies in iron and zinc are affecting an increasing number of people worldwide due to the low intake and bioavailability of minerals from traditional diets based with little or no meat, fruit and vegetables. Using X-ray Spectroscopy at Diamond scientists at Rothamsted Research were able to investigate the distribution and complexation of mineral deposits in different varieties of grain to understand the digestibility of the wheat.

Understanding the microstructure of ice cream

The quality of ice cream is considered to depend on the size of constituent air cells and ice crystals, the smaller and rounder the better. Product quality and shelf life can be strongly affected by the temperature variations that can commonly occur during storage and distribution. Teams from the University of Manchester and Unilever used in situ X-ray tomography to study the microstructure of ice-cream under different processing conditions to see how this affects the taste.

The quality of ice cream is considered to depend on the size of constituent air cells and ice crystals, the smaller and rounder the better. Product quality and shelf life can be strongly affected by the temperature variations that can commonly occur during storage and distribution. Teams from the University of Manchester and Unilever used in situ X-ray tomography to study the microstructure of ice-cream under different processing conditions to see how this affects the taste.

Producing credible plant-based alternatives to meat.

Consumers in Thailand have provided a challenge for the food industry - to maintain the desired flavour and experience of eating meat, whilst turning to more plant-based sources. A team from SLRI synchrotron and Algeaba used chlorophyll from algae to create a new form of food supplement similar to heme (a source of iron in animals). They performed X-ray Aborption Spectroscopy (XAS) on the samples to study the local structure and bonding activities taking place.

Consumers in Thailand have provided a challenge for the food industry - to maintain the desired flavour and experience of eating meat, whilst turning to more plant-based sources. A team from SLRI synchrotron and Algeaba used chlorophyll from algae to create a new form of food supplement similar to heme (a source of iron in animals). They performed X-ray Aborption Spectroscopy (XAS) on the samples to study the local structure and bonding activities taking place.

Working with the Industrial Liaison team isn't just about accessing Diamond's advanced scientific facilities. We have a dedicated team of experts to help you get the most out of your experiments and to ensure you achieve actionable results. They will support you throughout your experiment, and can:

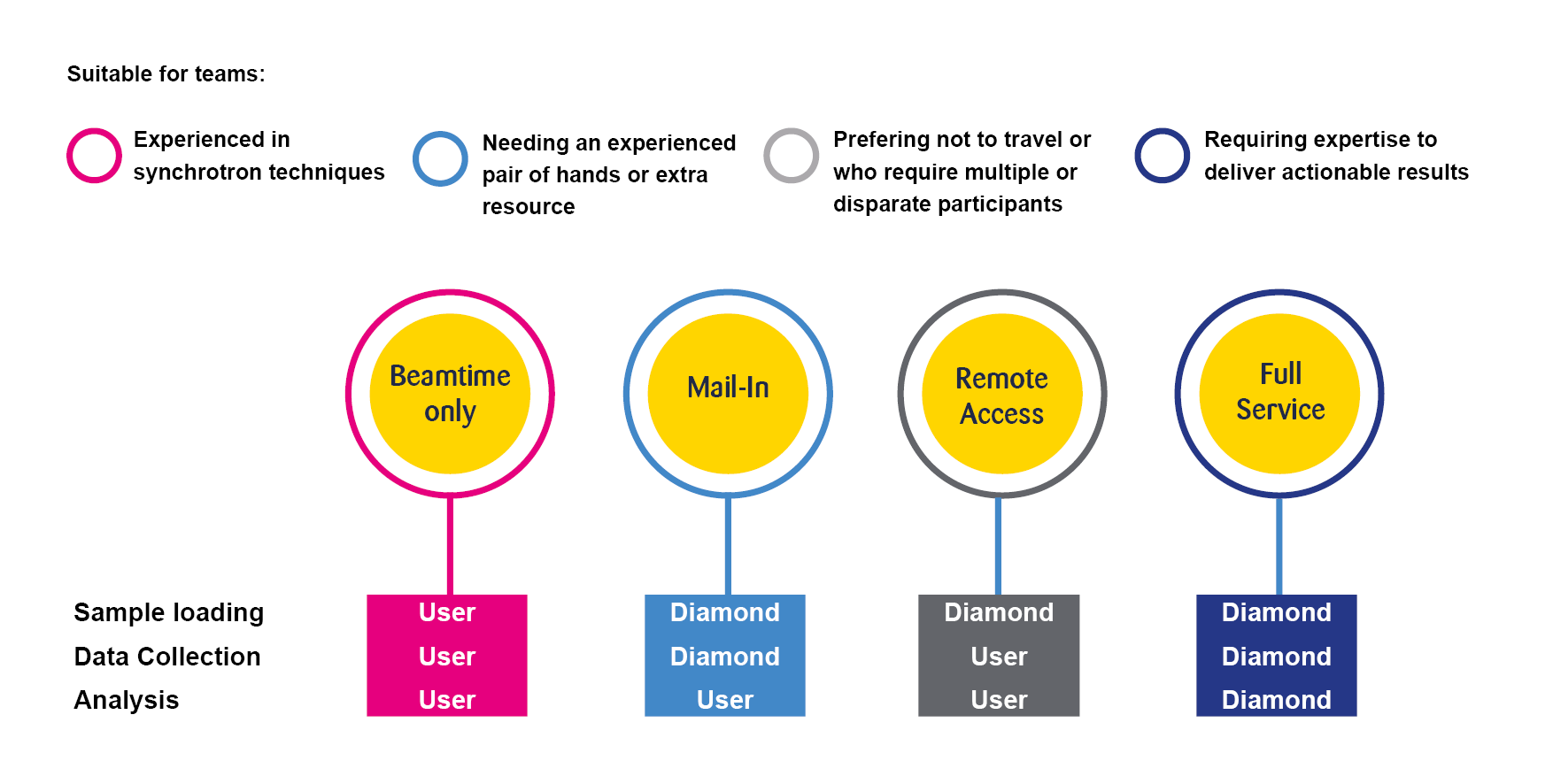

You can choose from a number of different access levels to suit your particular requirements. So, whatever your level of expertise, we have an option available for you.

To find out more about research techniques at Diamond, or to discuss potential applications for food, please contact the Industrial Liaison team on 01235 778797 or complete an enquiry form.

You can also keep in touch with the latest development by following us on Twitter @DiamondILO or LinkedIn or join our mailing list.

Diamond Light Source is the UK's national synchrotron science facility, located at the Harwell Science and Innovation Campus in Oxfordshire.

Copyright © 2022 Diamond Light Source

Diamond Light Source Ltd

Diamond House

Harwell Science & Innovation Campus

Didcot

Oxfordshire

OX11 0DE

Diamond Light Source® and the Diamond logo are registered trademarks of Diamond Light Source Ltd

Registered in England and Wales at Diamond House, Harwell Science and Innovation Campus, Didcot, Oxfordshire, OX11 0DE, United Kingdom. Company number: 4375679. VAT number: 287 461 957. Economic Operators Registration and Identification (EORI) number: GB287461957003.