___________________________________

Industrial Liaison Group:

Tel: +44 (0) 1235 778797

E-mail: [email protected]

With the food market producing a total revenue of US$6,954 billion1 a year (2019) worldwide and £148million2 in the UK, it’s surprising that on average only 0.5% of this is spent on R&D. With the market set to grow at a CAGR of 1.17% between 2021 and 20252 and new pressures from legislation, customer demands and the rising cost of raw materials, this trend is sure to end.

Most innovation has traditionally come out of the big brand companies, or more recently from small artisan producers who are more agile to change. However, the market has started to change and more food companies are now investing in dedicated product development teams and some even outsourcing this to save on overheads.

Diamond works with a number of companies in the food industry – from exploring the effects of new formulations and processing conditions to investigating packaging materials and trace food contaminants. All of this is only possible by exploring the science behind the product, and here at Diamond we have advanced characterisation tools to enable this to be done at a molecular level.

Our dedicated industry team are all experts in different fields of synchrotron research techniques and work closely with our clients to fully understand requirements before recommending the most effective approach. They can support you throughout your experiment, or indeed collect data on your behalf and provide a detailed report analysing the results.

We work within a highly confidential framework so we’re unable to share details of most of our work. However, below are a few examples of research we have conducted with food companies at Diamond.

With the aim of improving the nutritional value of diets, scientists at Rothampstead Research combined X-ray fluorescence (XRF) and X-ray absorption spectroscopy to investigate the distribution of different mineral components in staple foods. To find out more read our case study.

X-ray imaging allowed scientists at Unilever and the University of Manchester to study how processing conditions and ingredients affect the taste of ice cream. To find out more read our case study.

Our food poster demonstrates the opportunities for food research at Diamond and showcases the applications. Take a look to find out more.

SLRI synchrotron & Algeaba used X-ray absorption spectroscopy to study the structure of a heme substitute. This would enable consumers in Thailand to follow a plant-based diet whilst maintaining the desired qualities & taste of meat. to find out more, read our case study.

Claire Pizzey, Deputy Head of Industrial Liaison speaks to the Institute of Food Science and Technology to demonstrate the benefits of using Diamond for the characterisation of foods and food ingredients, to understand their properties and behaviour. To find out more, read the article.

Claire Pizzey, Deputy Head of Industrial Liaison speaks to the Institute of Food Science and Technology to demonstrate the benefits of using Diamond for the characterisation of foods and food ingredients, to understand their properties and behaviour. To find out more, read the article.

Claire Pizzey from our Industry team recently spoke to representatives from the food industry at Harwell's Food Technology event. If you missed her talk, here's your opportunity to watch it.

Low calorie alternatives for confectionary

Low calorie alternatives for confectionary

Nestle study the properties of the fat crystals contained in oleogels to optimise manufacturing processes and product quality.

The impact of Selenium and a biostimulant on wheat grain development

The impact of Selenium and a biostimulant on wheat grain development

Scientists investigate the Se location in wheat grain and its chemical speciation at different stages of wheat growth.

Releasing healthy isoflavones from Soyabean

Releasing healthy isoflavones from Soyabean

A novel enzyme, effective in extreme processing conditions, is investigated as a means to hydrolyse the main isoflavone glucosides present in soybean flour.

Iron in cornflakes

Iron in cornflakes

Scientists study two leading brands of breakfast cereal to determine the speciation of the iron present & therefore the level of absorption into the body.

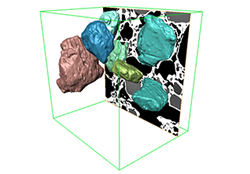

3D X-ray tomography scoops up information about ice cream microstructure

3D X-ray tomography scoops up information about ice cream microstructure

Researchers investigate the temperature dependence of microstructural changes, and the underlying physical mechanisms that control microstructural stability.

Getting zinc where it’s needed

Getting zinc where it’s needed

A European research team engineer barley to concentrate zinc in the edible portion of barley grain.

We have used many different techniques to research food, Here are a few of the most used to date.

Diffraction

Diffraction

For structural analysis of materials from the atomic to macro scale. Find out how this technique can be applied to the food industry

Spectroscopy

Spectroscopy

For chemical analysis of local atomic structure in materials. Find out how this technique can be applied to the food industry

Imaging

Imaging

A high-resolution, non-destructive technique for high speed visualisation of a sample. Find out how this technique can be applied to the food industry

To find out more about food research at Diamond, or to discuss potential industrial applications, please complete an enquiry form or contact the Industrial Liaison team on 01235 778797. You can keep in touch with the latest development by following us on Twitter @DiamondILO or LinkedIn.

1 https://www.statista.com/study/55496/food-report-2021/

2 https://www.statista.com/outlook/cmo/food/united-kingdom

Diamond Light Source is the UK's national synchrotron science facility, located at the Harwell Science and Innovation Campus in Oxfordshire.

Copyright © 2022 Diamond Light Source

Diamond Light Source Ltd

Diamond House

Harwell Science & Innovation Campus

Didcot

Oxfordshire

OX11 0DE

Diamond Light Source® and the Diamond logo are registered trademarks of Diamond Light Source Ltd

Registered in England and Wales at Diamond House, Harwell Science and Innovation Campus, Didcot, Oxfordshire, OX11 0DE, United Kingdom. Company number: 4375679. VAT number: 287 461 957. Economic Operators Registration and Identification (EORI) number: GB287461957003.