___________________________________

Industrial Liaison Group:

Tel: +44 (0) 1235 778797

E-mail: [email protected]

Diamond provides specialist analytical techniques for the atomic to microscale characterisation of materials ranging from biopharmaceuticals and food to hair care products, performance coatings and engine oil additives. The insight can be obtained at all stages of the product life cycle from initial product development through to monitoring formulation behaviour in end-use applications.

A key benefit of synchrotron facilities like Diamond is the ability to perform in situ and operando experiments, closely mimicking the conditions experienced by the sample during processing and monitoring changes in real time (for example heating or mixing).

Our dedicated Industrial Liaison Team of highly skilled scientists can help to translate your R&D challenges into meaningful analytical solutions by making use of its diverse expertise in synchrotron methods. Each member is a specialist in a different technique; we are therefore able to provide a multi-disciplinary approach to solving research and development problems across a wide variety of industries.

Our flexible approach means that we can prepare a tailored package for you depending on the needs of each of your projects and we charge only for the time and services you actually need. We are able to offer support with as much or as little of the project as you need.

Below are examples of some of the industries we work with and the value we’ve added to our customers’ research.

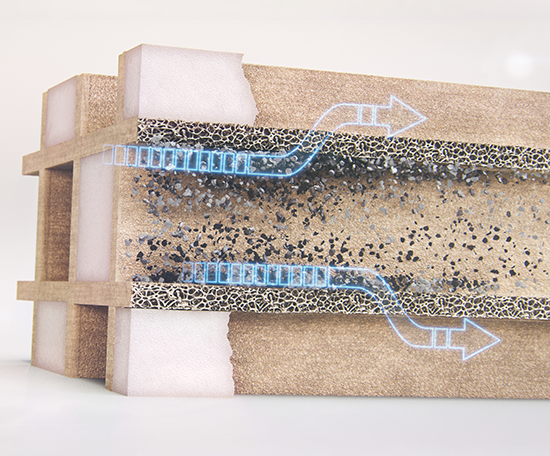

“The high-resolution XRT data collected at Diamond’s leading facilities have allowed Lubrizol to build further understanding into the role of our additive chemistry on GPF performance and durability. Whilst directly contributing to increased vehicle efficiency through our additive chemistries, this data also ensures we will continue to enable the world to move cleaner through effective advanced after-treatment systems.”

“The high-resolution XRT data collected at Diamond’s leading facilities have allowed Lubrizol to build further understanding into the role of our additive chemistry on GPF performance and durability. Whilst directly contributing to increased vehicle efficiency through our additive chemistries, this data also ensures we will continue to enable the world to move cleaner through effective advanced after-treatment systems.”

Dr Paul Kirkman, Lubrizol Ltd.

“The unique qualities of the Diamond-Manchester branchline (in-line phase contrast in pink beam) allowed us to study how processing conditions and ingredients affect the taste of ice cream, helping us better understand our product. By collaborating with Manchester we developed an in situ rig that replicated the processing conditions making it all possible.”

“The unique qualities of the Diamond-Manchester branchline (in-line phase contrast in pink beam) allowed us to study how processing conditions and ingredients affect the taste of ice cream, helping us better understand our product. By collaborating with Manchester we developed an in situ rig that replicated the processing conditions making it all possible.”

Dr Julian Bent, Unilever

"Working with Diamond gives you access to world class experts and facilities and Diamond offers a specialist technique that isn't something many companies would have the ability to do themselves.

"Working with Diamond gives you access to world class experts and facilities and Diamond offers a specialist technique that isn't something many companies would have the ability to do themselves.

SAXS is a very sensitive technique and it can detect tiny structural changes. No crystal was needed, so we just provided the sample in solution.

We had telephone conversations before and after the study and received a detailed report of our results, which was really good. The people at Diamond were very quick to respond to our queries."

Dr Dave Gervais, Porton Biopharma

“Wonderful things can happen when you bring together imaginative academic, industrial and Diamond people together with the best scientific facilities! Access to I22 SAXS beamline at Diamond made a real difference to the development of our project. We were able to apply a purpose-built liquid cell with acoustic transducers into the beam and look at the associations and dissociations of molecules with and without an applied acoustic field. Using model compounds to simulate food and fuels we were able to observe all the changes and make adjustments in real time. The support of the team at Diamond was invaluable in making this happen and we were able to immediately check our theories and later verify them when all the data was examined.”

“Wonderful things can happen when you bring together imaginative academic, industrial and Diamond people together with the best scientific facilities! Access to I22 SAXS beamline at Diamond made a real difference to the development of our project. We were able to apply a purpose-built liquid cell with acoustic transducers into the beam and look at the associations and dissociations of molecules with and without an applied acoustic field. Using model compounds to simulate food and fuels we were able to observe all the changes and make adjustments in real time. The support of the team at Diamond was invaluable in making this happen and we were able to immediately check our theories and later verify them when all the data was examined.”

Prof. Ken Lewtas, Lewtas Science & Technologies

“The excellent facilities, flexibility and ‘can do’ attitude at the Diamond Light Source aligned well with our project needs and objectives. Without this contribution we would not have our current best prototype option to hand.”

“The excellent facilities, flexibility and ‘can do’ attitude at the Diamond Light Source aligned well with our project needs and objectives. Without this contribution we would not have our current best prototype option to hand.”

Dr Ian Tucker, Dr Cesar Mendoza,

Dr Julia Li, Unilever R&D Port Sunlight

The dedicated industry team makes all of these amazing research projects possible. Each an expert in specific synchrotron techniques, they can help you to get the most out of your time at Diamond.

To find out more about our services for Industry, or to discuss potential industrial applications, please contact the Industrial Liaison team on 01235 778797 or send us an e-mail. You can keep in touch with the latest development by following us on Twitter @DiamondILO or LinkedIn.

Diamond Light Source is the UK's national synchrotron science facility, located at the Harwell Science and Innovation Campus in Oxfordshire.

Copyright © 2022 Diamond Light Source

Diamond Light Source Ltd

Diamond House

Harwell Science & Innovation Campus

Didcot

Oxfordshire

OX11 0DE

Diamond Light Source® and the Diamond logo are registered trademarks of Diamond Light Source Ltd

Registered in England and Wales at Diamond House, Harwell Science and Innovation Campus, Didcot, Oxfordshire, OX11 0DE, United Kingdom. Company number: 4375679. VAT number: 287 461 957. Economic Operators Registration and Identification (EORI) number: GB287461957003.