____________________________________

Industrial Liaison Group:

Tel: +44 (0) 1235 778797

E-mail: [email protected]

The size and diffraction quality of crystals remain the major limiting factors of macromolecular crystallography (MX). Many crystals of challenging targets are small, weakly diffracting and indeed extremely sensitive to manual handling. The time consuming and often damaging process of cryo-protecting, mounting and cryocooling of crystals can significantly decrease the crystal order, resolution and overall quality of the data.

For virus crystals, cryo-cooling can worsen the diffraction resolution limit and also lead to increased mosaicity causing overlaps of diffraction spots. Membrane protein crystals represent an example of highly fragile and disordered samples which can be hard to visualise due to growth in the mesophase.

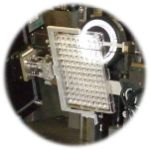

A system for mounting crystallisation trays has been developed for in situ crystal screening and data collection for beamlines I03, I04-1 and I24. Plates can be attached directly to the goniometer on I03 and I24 allowing high precision positioning and offering the advantage of implementing the diffraction grid scan. This addresses the problem of poor visualisation and optical effects of crystallisation plates during crystal centring.

The ability to collect diffraction data from crystals still located in SBS format plates, allows the pharmaceutical industry to rapidly assess the outcome of numerous ligand soaks in an efficient manner, thereby directing optimisation of their drug discovery process. It also removes the need for cryo-cooling and manual handling of crystals, both of which can reduce the diffraction quality of certain classes of macromolecule and it is suitable for investigating containment level 3 samples.

“In situ data collection is a dream for virus crystallographers. Virus crystals have large unit cells and can be rather fragile, not to mention hazardous – so not having to manipulate the crystals significantly reduces the risks to the crystals themselves and to those handling them! Collecting cryo-cooled data is often an impossible or undesirable option. At room temperature the crystals have a short lifetime in the beam so it is extremely neat being able to navigate around the plate and shoot the crystals without constant trips in and out of the hutch to change them. The whole process is now much faster and more efficient and the structures are rolling. Thanks to all the staff on I24 and I03 for implementing this.”

Dr Elizabeth Fry, Structural Biology Division, WTCHG, University of Oxford

Diamond Light Source is the UK's national synchrotron science facility, located at the Harwell Science and Innovation Campus in Oxfordshire.

Copyright © 2022 Diamond Light Source

Diamond Light Source Ltd

Diamond House

Harwell Science & Innovation Campus

Didcot

Oxfordshire

OX11 0DE

Diamond Light Source® and the Diamond logo are registered trademarks of Diamond Light Source Ltd

Registered in England and Wales at Diamond House, Harwell Science and Innovation Campus, Didcot, Oxfordshire, OX11 0DE, United Kingdom. Company number: 4375679. VAT number: 287 461 957. Economic Operators Registration and Identification (EORI) number: GB287461957003.